High-temperature-resistant heat dissipation coating and preparation method thereof

A heat-dissipating coating and high-temperature-resistant technology, applied in the coating field, can solve the problem that nano-carbon materials cannot obtain sufficient heat resistance, and achieve the effects of good crack resistance, good mechanical properties, flexibility and elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

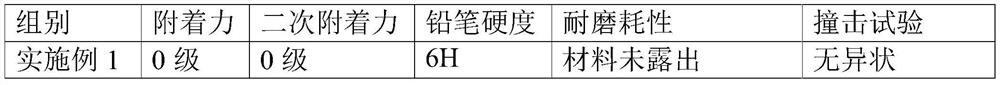

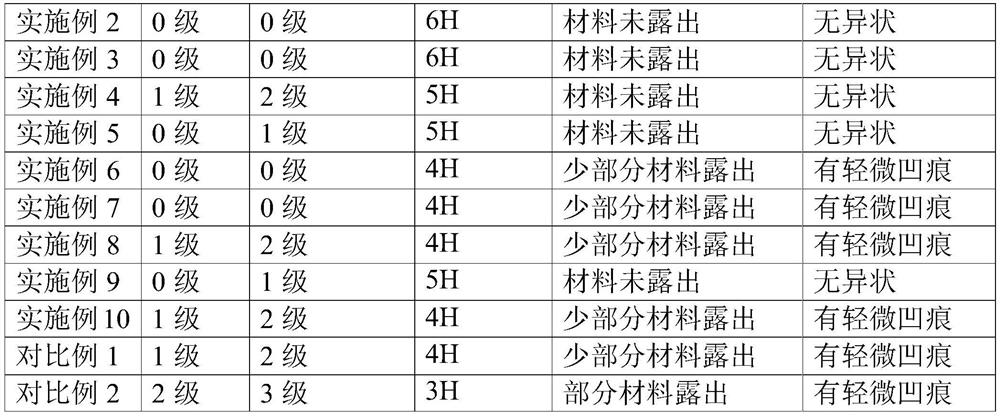

Examples

Embodiment 1

[0045] This embodiment provides a method for preparing a high-temperature-resistant heat-dissipating coating, which specifically includes the following steps:

[0046] S1. Preparation of metal oxide nanopowder: Dissolve 4g of ferric nitrate, 13g of aluminum nitrate, and 1g of cobalt nitrate in 100mL of water, add 30g of citric acid, disperse with 1000W ultrasonic wave for 30min, heat to 45°C and evaporate for 1h to obtain a sol; then increase To 170°C, the vacuum degree is 0.01MPa, forming a xerogel, taking it out, igniting the xerogel, and obtaining metal oxide nanopowder;

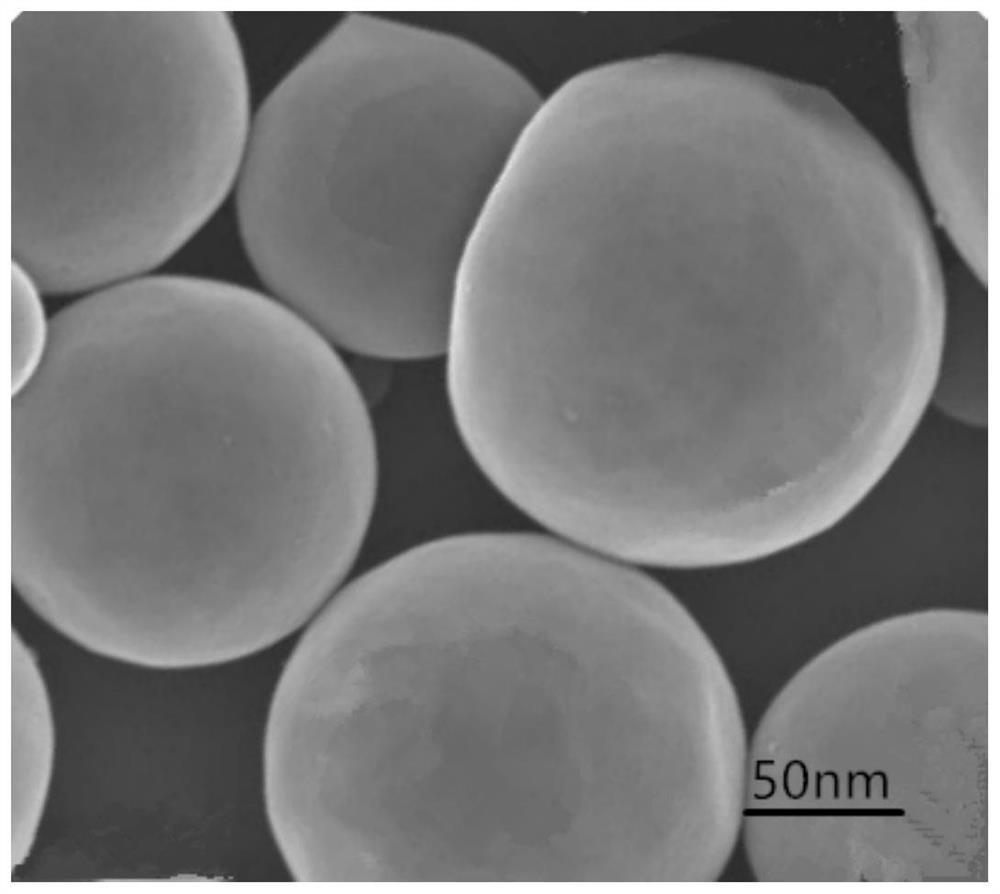

[0047] S2. Preparation of polydopamine / metal oxide nanopowder: add 10g of metal oxide nanopowder prepared in step S1 to 100mL water, 2000W ultrasonic dispersion for 30min, add 17g dopamine hydrochloride, add 1g Tris- HCl solution, heated to 40°C and stirred for 3h, centrifuged at 3000r / min for 15min, washed with deionized water, and dried at 70°C for 4h to obtain polydopamine / metal oxide nanopowder; figu...

Embodiment 2

[0053] This embodiment provides a method for preparing a high-temperature-resistant heat-dissipating coating, which specifically includes the following steps:

[0054] S1. Preparation of metal oxide nanopowder: Dissolve 12g of ferric nitrate, 13g of aluminum nitrate, and 5g of cobalt nitrate in 100mL of water, add 40g of citric acid, disperse with 1000W ultrasonic wave for 30min, heat to 55°C and evaporate for 1h to obtain a sol; then increase To 200°C, the vacuum degree is 0.1MPa, forming a xerogel, taking it out, igniting the xerogel, and obtaining metal oxide nanopowder;

[0055] S2. Preparation of polydopamine / metal oxide nanopowder: add 10g of metal oxide nanopowder prepared in step S1 to 100mL water, 2000W ultrasonic dispersion for 30min, add 22g dopamine hydrochloride, add 2g Tris- HCl solution, heated to 50°C and stirred for 5h, centrifuged at 3000r / min for 15min, washed with deionized water, and dried at 70°C for 4h to obtain polydopamine / metal oxide nanopowder;

[0...

Embodiment 3

[0061] This embodiment provides a method for preparing a high-temperature-resistant heat-dissipating coating, which specifically includes the following steps:

[0062] S1. Preparation of metal oxide nanopowder: Dissolve 8g of ferric nitrate, 13g of aluminum nitrate, and 3g of cobalt nitrate in 100mL of water, add 35g of citric acid, disperse with 1000W ultrasonic wave for 30min, heat to 50°C and evaporate for 1h to obtain a sol; To 185°C, the vacuum degree is at 0.05MPa, to form xerogel, take it out, ignite the xerogel, and obtain metal oxide nanopowder;

[0063] S2. Preparation of polydopamine / metal oxide nanopowder: add 10g of the metal oxide nanopowder prepared in step S1 into 100mL water, 2000W ultrasonic dispersion for 30min, add 20g dopamine hydrochloride, add 1.5g Tris with a pH value of 8.2 -HCl solution, heated to 45°C and stirred for 4h, centrifuged at 3000r / min for 15min, washed with deionized water, and dried at 70°C for 4h to obtain polydopamine / metal oxide nanopo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com