Electronic material glue solution and preparation method thereof

A technology of electronic materials and glue, which is applied in the direction of adhesives, epoxy resin glue, polymer adhesive additives, etc., can solve the problems of glue viscosity increase, affecting processing performance, mechanical performance, etc., to achieve moderate curing temperature, Effects of life extension and high dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

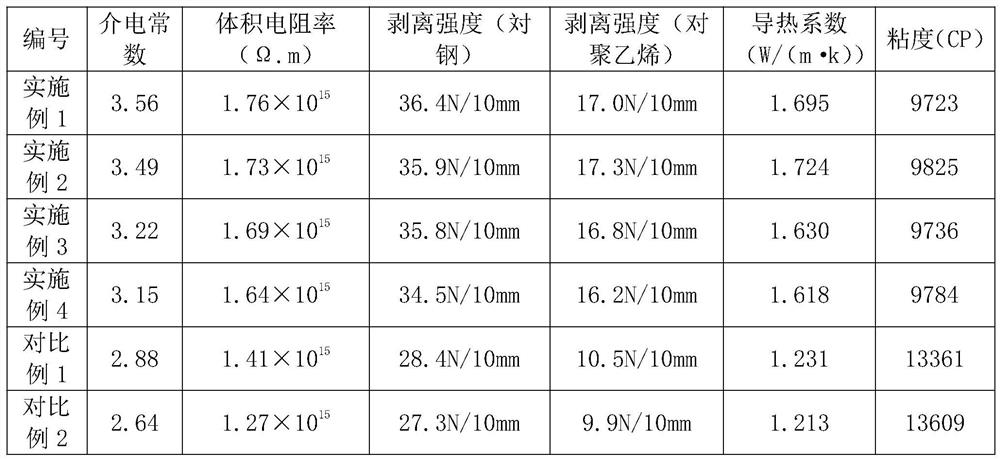

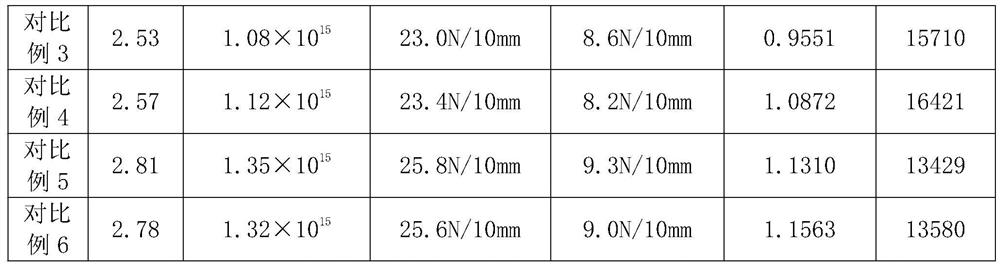

Embodiment 1

[0035] An electronic material glue, which is made by mixing component A and curing agent in a weight ratio of 100:8. The component A is composed of the following raw materials in the following weight ratio: 80 parts of improved high thermal conductivity components, epoxy resin 10 parts, 1 part of coupling agent, 2 parts of viscosity modifier, 0.05 parts of catalyst, 1 part of dispersant and 1 part of toughening agent.

[0036] Specifically, the curing agent is 650 low molecular weight polyamide resin.

[0037] Specifically, the preparation method of the improved high thermal conductivity component includes the following steps:

[0038] S1: Grinding non-spherical alumina in a ball mill to obtain fine-grained alumina powder for later use;

[0039] S2: Put anhydrous ethanol: fine-grained alumina powder: silicone resin: Brunei glue in a mixer in a ratio of 30:6:1:1 to disperse evenly to make a spray liquid;

[0040] S3: Carry out spray granulation to the spray liquid, and then c...

Embodiment 2

[0053] An electronic material glue, which is formed by mixing component A and curing agent in a weight ratio of 100:10. The component A is composed of the following raw materials in the following weight ratio: 90 parts of improved high thermal conductivity components, epoxy resin 15 parts, 3 parts of coupling agent, 3 parts of viscosity modifier, 0.1 part of catalyst, 1.5 parts of dispersant and 2 parts of toughening agent.

[0054] Specifically, the curing agent is 650 low molecular weight polyamide resin.

[0055] Specifically, the preparation method of the improved high thermal conductivity component includes the following steps:

[0056] S1: Grinding non-spherical alumina in a ball mill to obtain fine-grained alumina powder for later use;

[0057] S2: Put anhydrous ethanol: fine-grained alumina powder: silicone resin: Brunei glue in a mixer in a ratio of 30:6:1:1 to disperse evenly to make a spray liquid;

[0058] S3: Carry out spray granulation to the spray liquid, and ...

Embodiment 3

[0071] An electronic material glue, which is made by mixing component A and curing agent in a weight ratio of 100:8.5. The component A is composed of the following raw materials in the following weight ratio: 85 parts of improved high thermal conductivity components, epoxy resin 12 parts, 1.5 parts of coupling agent, 2.3 parts of viscosity modifier, 0.07 parts of catalyst, 1.3 parts of dispersant and 1.3 parts of toughening agent.

[0072] Specifically, the curing agent is 650 low molecular weight polyamide resin.

[0073] Specifically, the preparation method of the improved high thermal conductivity component includes the following steps:

[0074] S1: Grinding non-spherical alumina in a ball mill to obtain fine-grained alumina powder for later use;

[0075] S2: Put anhydrous ethanol: fine-grained alumina powder: silicone resin: Brunei glue in a mixer in a ratio of 30:6:1:1 to disperse evenly to make a spray liquid;

[0076] S3: Carry out spray granulation to the spray liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com