Composite coagulant for industrial wastewater treatment and preparation method thereof

A technology for industrial wastewater and coagulant, which is applied in water treatment parameter control, water/sewage treatment, adsorbed water/sewage treatment, etc. It can solve the problems of unsatisfactory decolorization effect, unstable effluent quality, and poor COD reduction ability. Achieve the effect of good solid-liquid separation, good coagulation effect and less sludge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

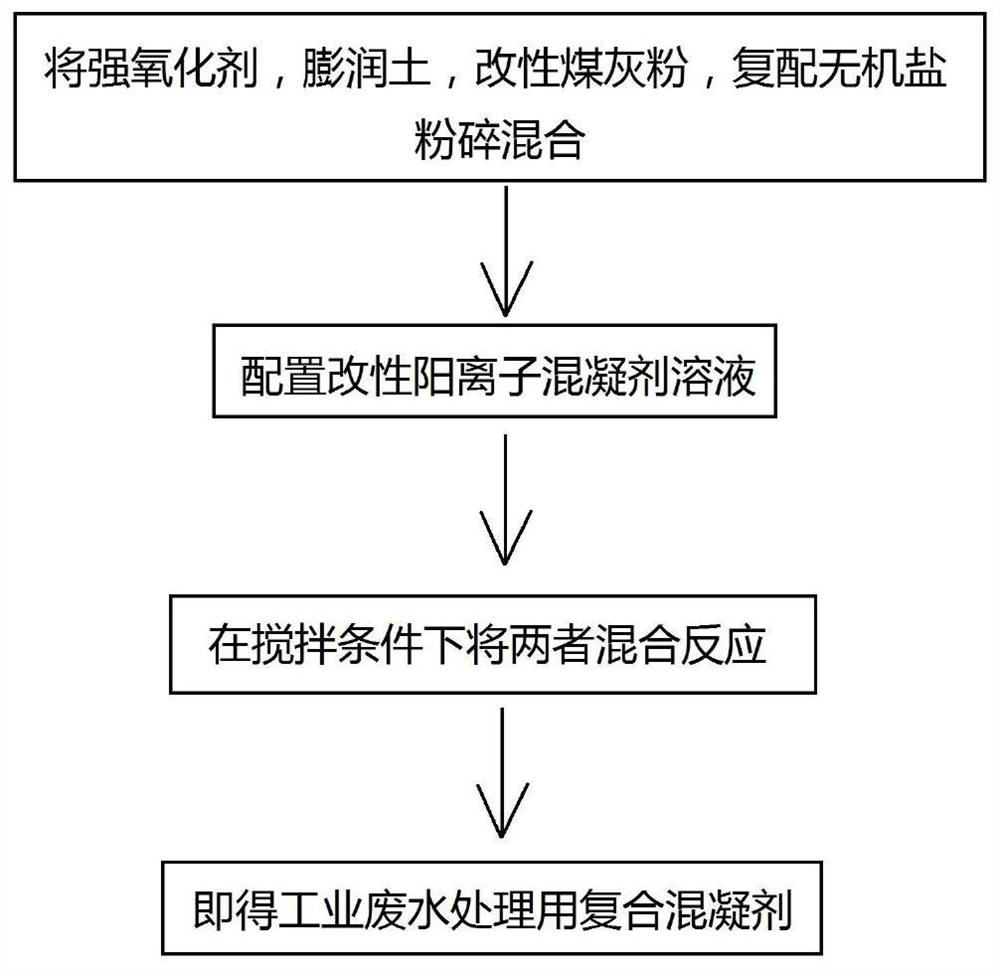

[0035] The components of the composite coagulant for industrial wastewater treatment in this embodiment are as follows: 1000 g of modified cationic coagulant, 20 g of strong oxidizing agent (sodium chlorate or potassium permanganate), 60 g of bentonite, 360 g of modified fly ash, With inorganic salt 40g.

[0036] Among them, the compound inorganic salt is CaCl with a mass ratio of 1:3:4 2 , MgCl 2 and FeCl 3 mixture.

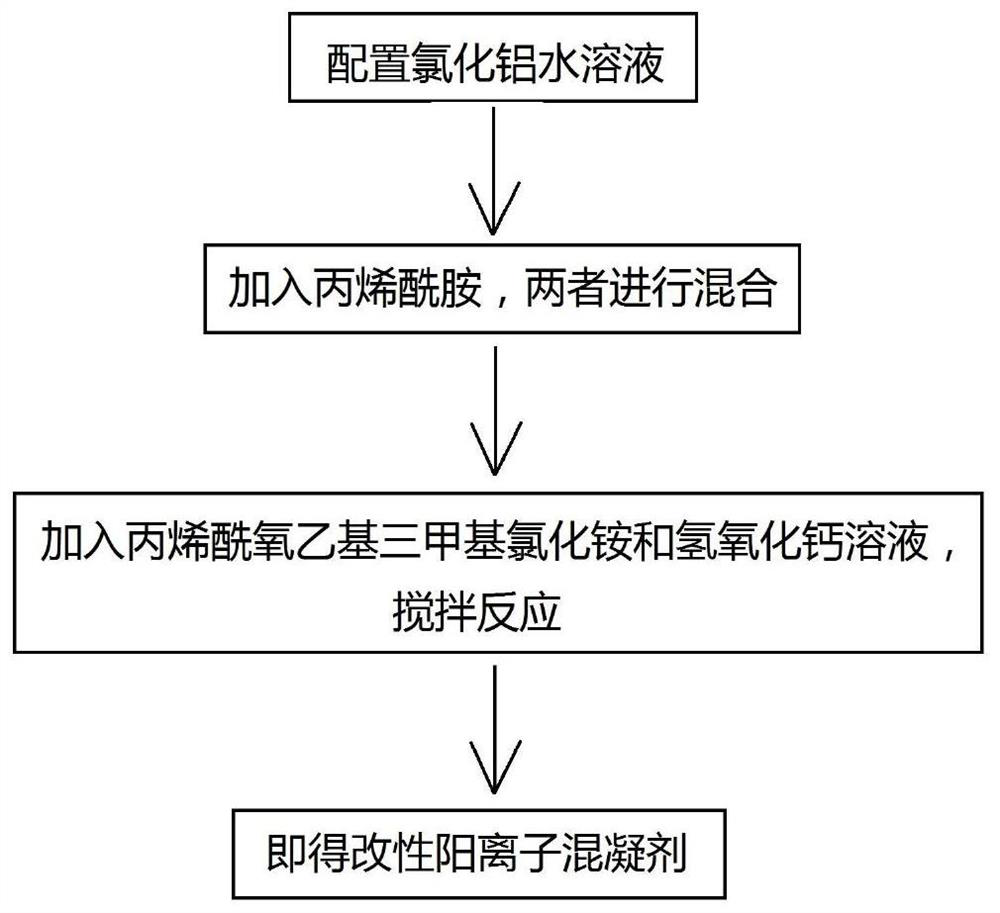

[0037] The preparation process of modified cationic coagulant, such as figure 1 Shown:

[0038] (1) aluminum chloride hexahydrate is dissolved in the hydrochloric acid solution of 0.2mol / L, is configured into the aluminum chloride aqueous solution that mass concentration is 58%;

[0039] (2) Add acrylamide and the aluminum chloride aqueous solution obtained in step (1) to the reaction vessel, the addition of acrylamide is 12% of the quality of aluminum chloride hexahydrate, stir and mix, and feed nitrogen to drive oxygen for 10 -20min;

[0040] (3) Add th...

Embodiment 2

[0047] The components of the composite coagulant for industrial wastewater treatment in this embodiment are as follows: 1000g of modified cationic coagulant, 40g of strong oxidizing agent (sodium chlorate or potassium permanganate), 100g of bentonite, 300g of modified fly ash, With inorganic salt 60g.

[0048] Among them, the compound inorganic salt is CaCl with a mass ratio of 1:5:2 2 , MgCl 2 and FeCl 3 mixture.

[0049] The preparation process of modified cationic coagulant is as follows:

[0050] (1) aluminum chloride hexahydrate is dissolved in the hydrochloric acid solution of 0.5mol / L, is configured into the aluminum chloride aqueous solution that mass concentration is 50%;

[0051] (2) Acrylamide and the aluminum chloride aqueous solution obtained in step (1) are added in the reaction vessel, the addition of acrylamide is 15% of the quality of aluminum chloride hexahydrate, stirring and mixing, and feeding nitrogen to drive oxygen for 10 -20min;

[0052] (3) Add ...

Embodiment 3

[0056] The components of the composite coagulant for industrial waste water treatment in this embodiment are as follows: 1000g of modified cationic coagulant, 50g of strong oxidizing agent (sodium chlorate or potassium permanganate), 80g of bentonite, 420g of modified fly ash, With inorganic salt 100g.

[0057] Among them, the compound inorganic salt is CaCl with a mass ratio of 1:6:3 2 , MgCl 2 and FeCl 3 mixture.

[0058] The preparation process of modified cationic coagulant is as follows:

[0059] (1) aluminum chloride hexahydrate is dissolved in the hydrochloric acid solution of 0.5mol / L, is configured into the aluminum chloride aqueous solution that mass concentration is 56%;

[0060] (2) Add acrylamide and the aqueous aluminum chloride solution obtained in step (1) to the reaction vessel, the amount of acrylamide added is 10% of the quality of aluminum chloride hexahydrate, stir and mix, and feed nitrogen to drive oxygen for 10 -20min;

[0061] (3) Add the dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com