Red light fluorescent powder capable of being used for blue light excitation of white light LED and preparation method of red light fluorescent powder

A technology of red light phosphor and blue light excitation, which is applied in nanotechnology, chemical instruments and methods, nano optics, etc. for materials and surface science. It can solve the problems of poor moisture resistance, non-luminescence, inactivation, etc., and meet the reaction conditions The effect of low requirements, simple process and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

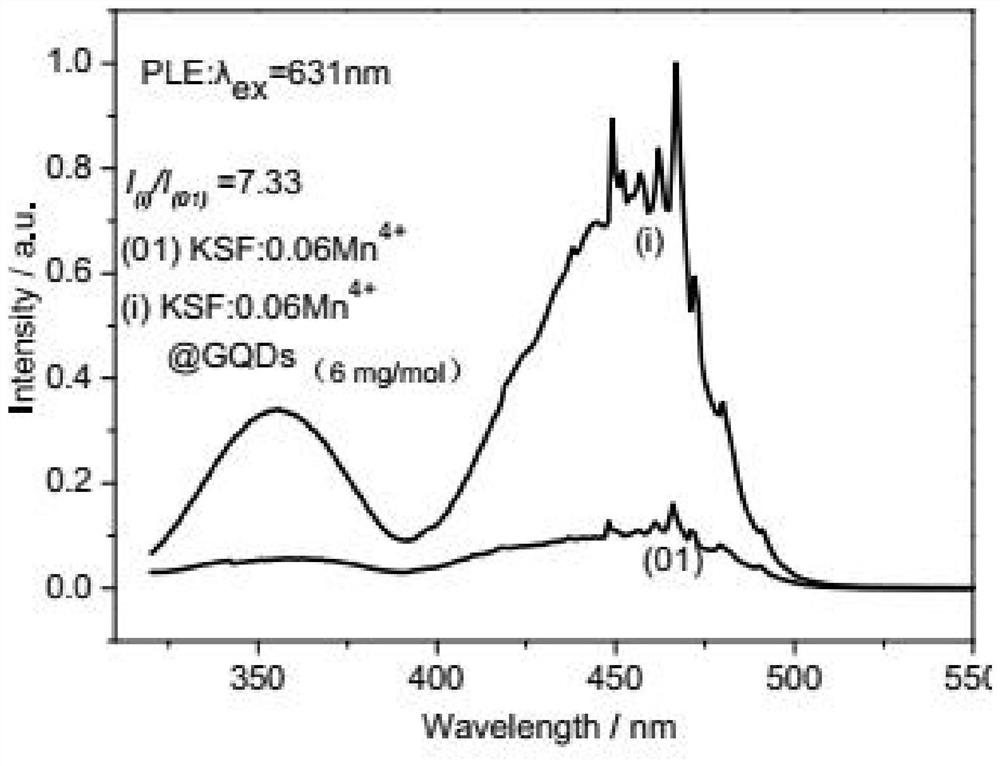

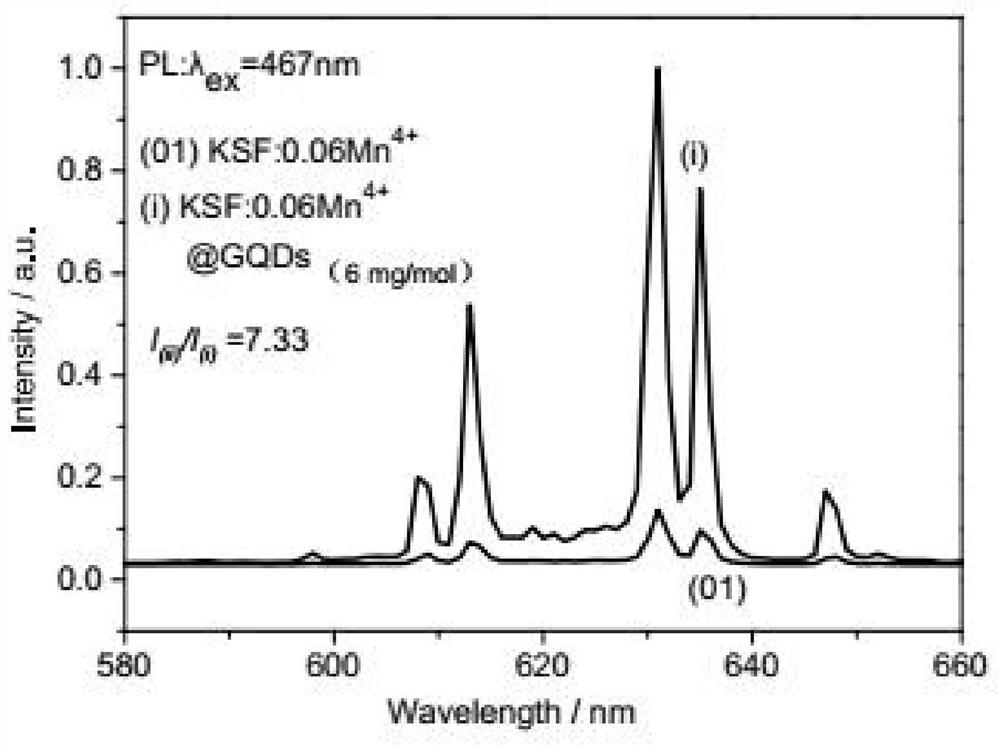

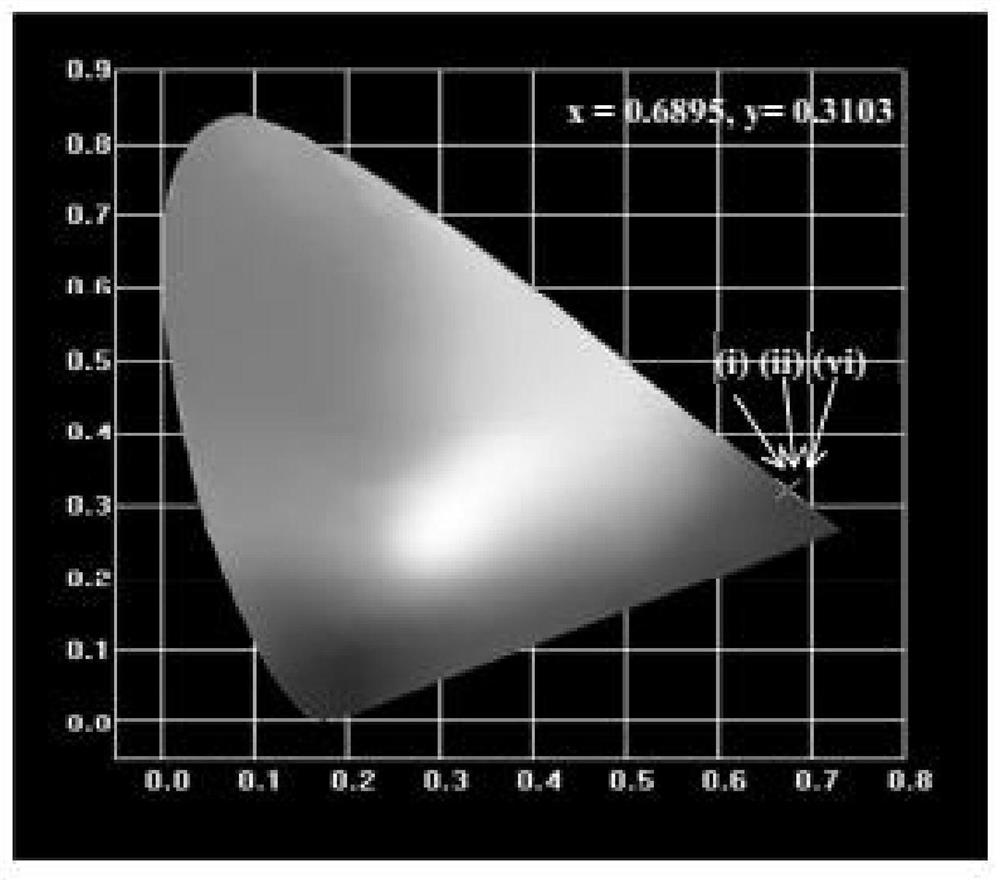

[0043] Embodiment 1 prepares [K 2 SiF 6 :0.06Mn 4+ @GQDs (6mg / mol) ](Abbreviated as: KSF:0.06Mn 4+ @GQDs (6mg / mol) )

[0044] (1) Take 24.0mL HF solution (mass concentration 40%) (V HF / W K2SiF6 =1.16mL / g), 12.00g KF 2H 2 O(W KF / W K2SiF6 =0.5), 0.9482g (6mmol) KMnO 4 The powder is placed in a 100mL plastic beaker, stirred with a magnetic stirrer at normal temperature and pressure until the solid material is completely dissolved to obtain a purple solution; then 20.71g (94.0mmol) K 2 SiF 6 Powder was added to the above solution (KMnO 4 / (K 2 SiF 6 +KMnO 4 ), x=0.06), seal the mouth of the beaker with plastic wrap, stir and react at normal temperature and pressure for 48h to obtain reaction mixture i, reaction mixture i is suction filtered, washed with absolute ethanol and then heated at 80°C Dry for 3 hours to obtain the uncoated sample, namely K 2 MF 6 :xMn 4+ Red phosphor crystal ((No. 01) sample).

[0045] (2) Slowly add 600 μL of green fluorescent GQDs ...

Embodiment 2

[0054] Embodiment 2 prepares [K 2 SiF 6 :0.03Mn 4+ @GQDs (6mg / mol) ](Abbreviated as: KSF:0.03Mn 4+ @GQDs (6mg / mol) )

[0055] Get 20.3mL HF solution (mass concentration 40%) (V HF / W K2SiF6 =0.95mL / g), 8.56g KF 2H 2 O(W KF / W K2SiF6 =0.40), 0.4741g (3.0mmol) KMnO 4 The powder is placed in a 100mL plastic beaker, stirred with a magnetic stirrer at normal temperature and pressure until the solid raw material is completely dissolved to obtain a purple-red solution; then 21.40g (97.0mmol) K 2 SiF 6 Powder was added to the above solution (KMnO 4 / (K 2 SiF 6 +KMnO 4 ), x=0.03), seal the mouth of the beaker with plastic wrap, stir and react at room temperature and pressure for 70h, then slowly add 600 μL of 1mg / mL to the above reaction mixture with a micropipette under stirring. After adding the green fluorescent GQDs solution, continue to stir for 25 minutes, then transfer the above mixture to a water heating tank; then put the sealed water heating tank in an oven, k...

Embodiment 3

[0058] Embodiment 3 prepares [K 2 TiF 6 :0.05Mn 4+ @GQDs (4mg / mol) ](abbreviated as: KTF:0.05Mn 4+ @GQDs (6mg / mol) )

[0059] (1) Take 21.89mL HF solution (mass concentration 40%) (V HF / W K2TiF6 =0.96mL / g), 10.26g KF 2H 2 O(W KF / W K2TiF6 =0.45), 0.7902g (5mmol) KMnO 4 The powder is placed in a 100mL plastic beaker, stirred with a magnetic stirrer at normal temperature and pressure until the solid raw material is completely dissolved to obtain a purple-red solution; then 22.81g (95.0mmol) K 2 TiF 6 Powder was added to the above solution (KMnO 4 / (K 2 TiF 6 +KMnO 4 ), x=0.05), seal the mouth of the beaker with plastic wrap, stir and react at normal temperature and pressure for 40h to obtain reaction mixture i, reaction mixture i is filtered by suction, washed with absolute ethanol and then heated at 80°C Dry for 3 hours to obtain the uncoated sample, namely K 2 MF 6 :xMn 4+ Red phosphor crystal ((No. 02) sample).

[0060] (2) Slowly add 400 μL of green fluo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| internal quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com