Non-heat-treated high-toughness die-casting aluminum-silicon alloy and preparation method thereof

A non-heat treatment, silicon alloy technology, applied in the field of metal materials, can solve the problems of reduced mold life, extremely high impurity content requirements, complex heat treatment process, etc., to achieve the effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

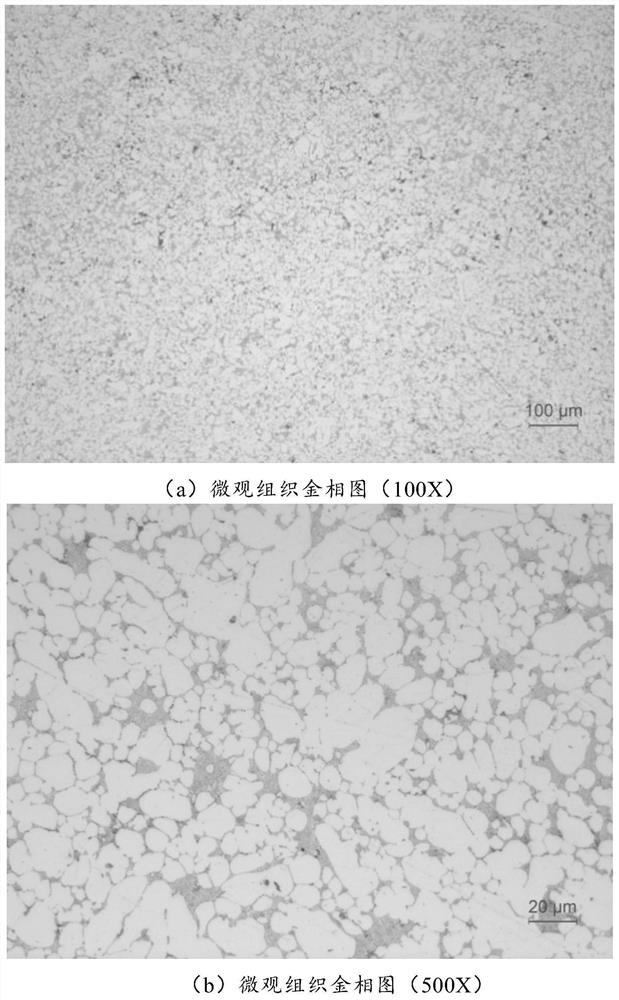

[0033] The percentage by weight of each component of a low-carbon emission renewable non-heat-treated high-toughness die-casting aluminum-silicon alloy in this embodiment is: Mg: 0.2%; Si: 6.5%; Fe: 0.15%; Cu: 0.1%; Mn: 0.5%; Ti: 0.03%; Sr: 0.025%; La, Ce total: 0.05%; Ni: 0.005%; Zn: 0.006%; Ga: 0.015%; .

[0034] A method for preparing a low-carbon emission renewable non-heat-treated high-toughness die-casting aluminum-silicon alloy in this embodiment includes the following steps:

[0035] (1) Furnace preparation: clean the bottom of the furnace and start to bake until the furnace wall turns red; paint all the operating tools with graphite powder and then dry and preheat;

[0036] (2) Ingredients: prepare metal Al ingot, metal Mg ingot, industrial Si, Al-Mn master alloy or metal Mn, metal Fe, Al-Ti master alloy, metal Cu or Al-Cu master alloy, metal Ni, metal Zn and Metal Ga, Al-Sr master alloy, aluminum rare earth master alloy, etc. are used as the raw materials of each e...

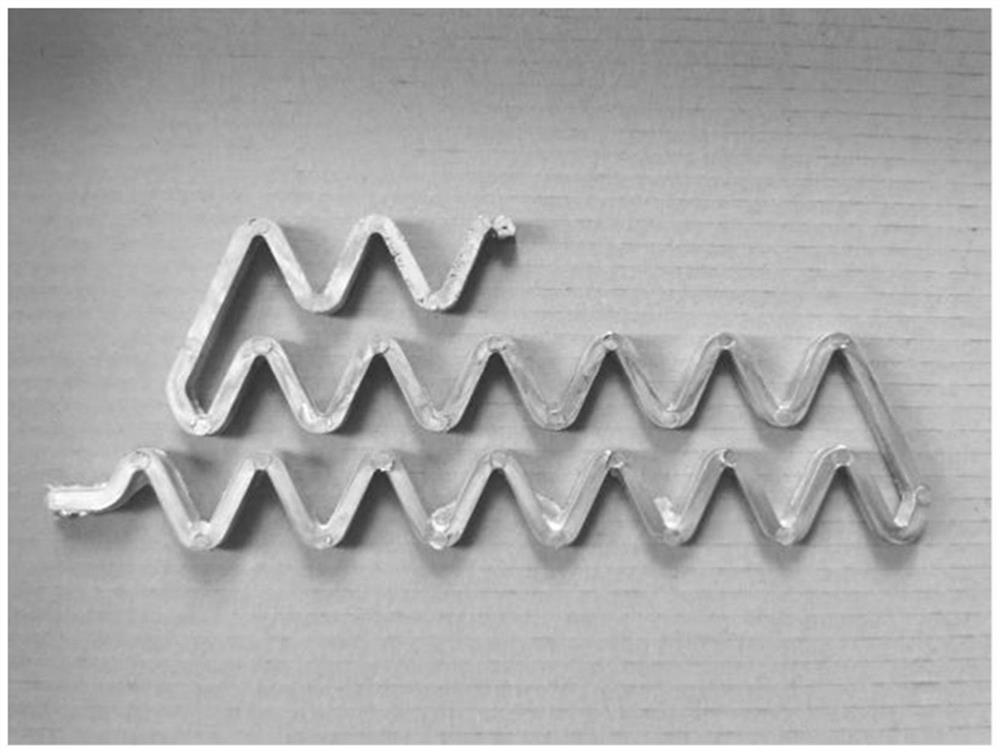

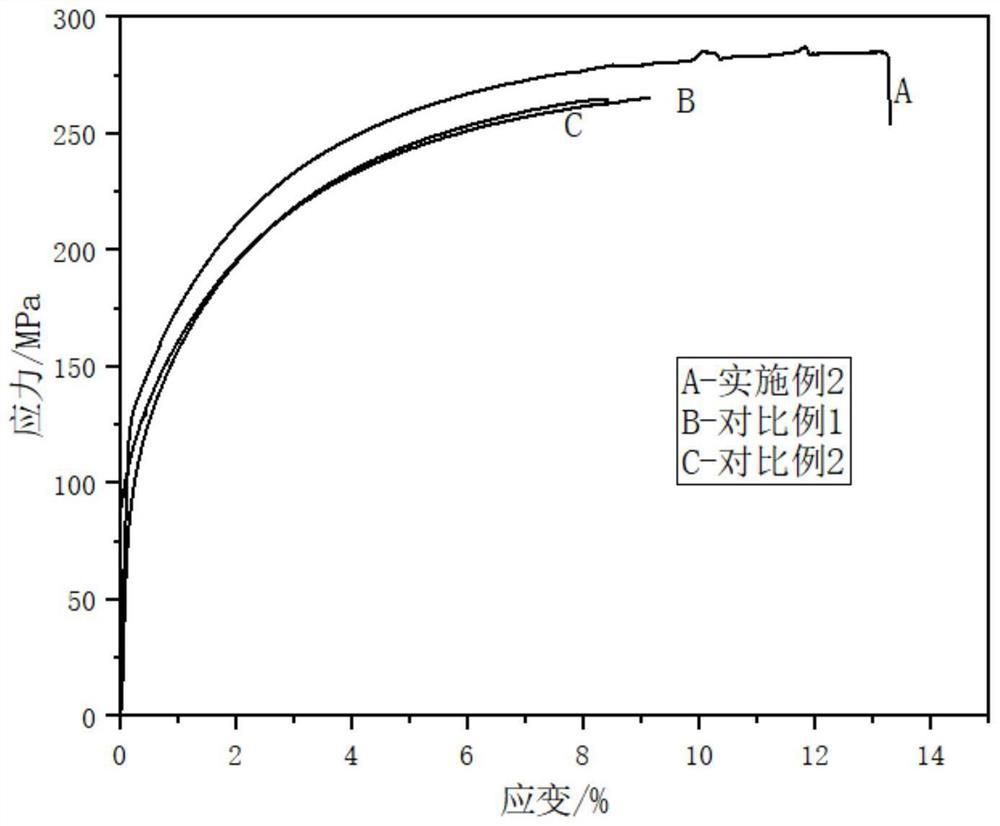

Embodiment 2

[0043] The percentage by weight of each component of a low-carbon emission renewable non-heat-treated high-toughness die-casting aluminum-silicon alloy in this embodiment is: Mg: 0.3%; Si: 6.9%; Fe: 0.2%; Cu: 0.2%; Mn: 0.6%; Ti: 0.07%; Sr: 0.02%; La: 0.1%; Ni: 0.003%; Zn: 0.07%;

[0044] A method for preparing a low-carbon emission renewable non-heat-treated high-toughness die-casting aluminum-silicon alloy in this embodiment includes the following steps:

[0045] (1) Furnace preparation: clean the bottom of the furnace and start to bake until the furnace wall turns red; paint all the operating tools with graphite powder and then dry and preheat.

[0046] (2) Ingredients: Prepare metal Al ingot or scrap aluminum, metal Mg ingot, industrial Si, Al-Mn master alloy or metal Mn, metal Fe, Al-Ti master alloy, metal Cu or Al-Cu master alloy, metal Ni, Metal Zn and metal Ga, Al-Sr master alloy, aluminum rare earth master alloy, etc. are used as raw materials for each element in the ...

Embodiment 3

[0053] The weight percent of each component of a low-carbon emission renewable non-heat-treated high-toughness die-casting aluminum-silicon alloy in this embodiment is: Mg: 0.35%; Si: 7.5%; Fe: 0.25%; Cu: 0.3%; Mn: 0.7%; Ti: 0.15%; Sr: 0.03%; Ce: 0.08%; Ni: 0.08%; Zn: 0.09%;

[0054] A method for preparing a low-carbon emission renewable non-heat-treated high-toughness die-casting aluminum-silicon alloy in this embodiment includes the following steps:

[0055] (1) Furnace preparation: clean the bottom of the furnace and start to bake until the furnace wall turns red; paint all the operating tools with graphite powder and then dry and preheat.

[0056] (2) Ingredients: Prepare metal Al ingot or scrap aluminum, metal Mg ingot, industrial Si, Al-Mn master alloy or metal Mn, metal Fe, Al-Ti master alloy, metal Cu or Al-Cu master alloy, metal Ni, Metal Zn and metal Ga, Al-Sr master alloy, aluminum rare earth master alloy, etc. are used as raw materials for each element in the alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com