Metal plating equipment

An equipment and metal technology, applied in the field of metal plating equipment, can solve the problems of increased cost, increased enterprise cost, and reduced process efficiency, and achieves the effect of reducing quantity requirements, saving time and cost, and improving process efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

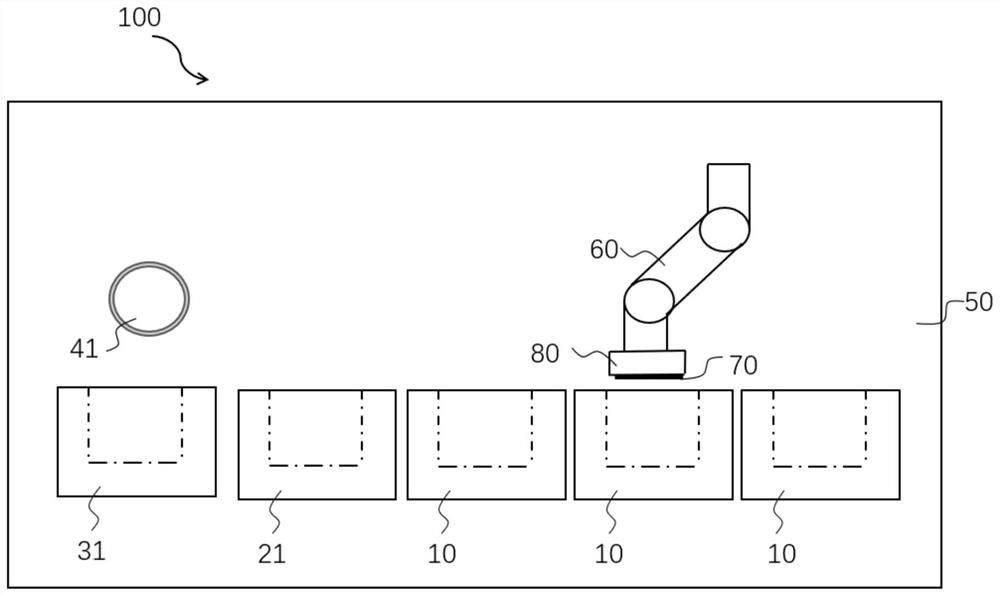

[0073] The present embodiment provides a kind of metal plating equipment 100, comprises a processing chamber 50, is integrated with a plurality of working tanks in the processing chamber 50, and working tank comprises plating tank 10 and process tank, and process tank comprises non-sealed processing process tank and sealed type treatment process tank, specifically, such as figure 1 As shown, in this embodiment, the non-sealed treatment process tank includes the non-sealed pre-treatment process tank 31 , and the sealed treatment process tank includes the sealed pre-treatment process tank 21 .

[0074] The processing chamber 50 is provided with a moving mechanism 60 and a wafer clamp 80, the wafer clamp 80 is used to clamp the wafer 70, the moving mechanism 60 is connected to the wafer clamp 80, the moving mechanism 60 can drive the wafer clamp 80 to move, non-sealed The pre-treatment tank 31 and the plating tank 10 share a wafer holder 80 . In addition, a first wafer holder co...

Embodiment 2

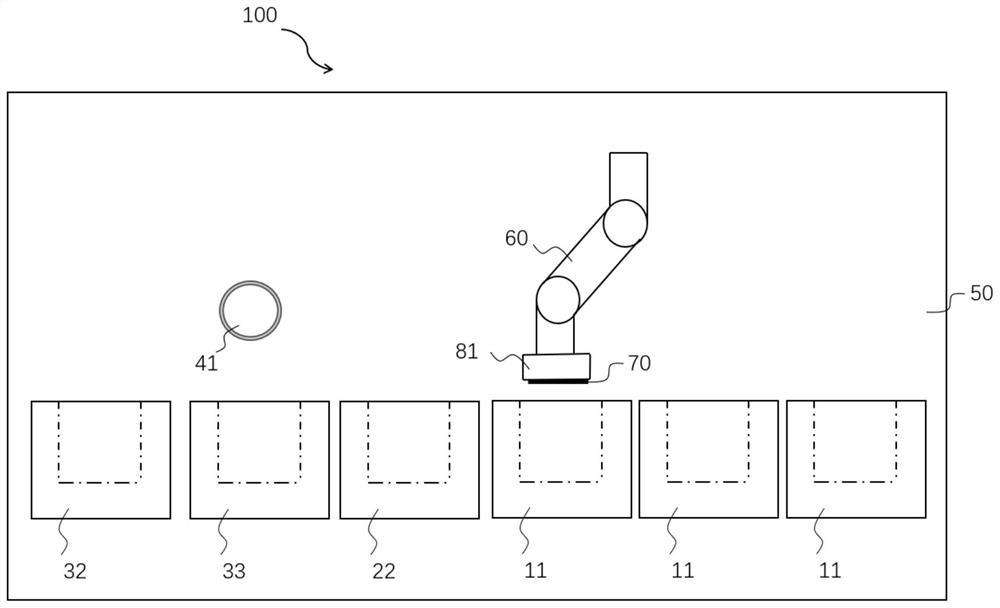

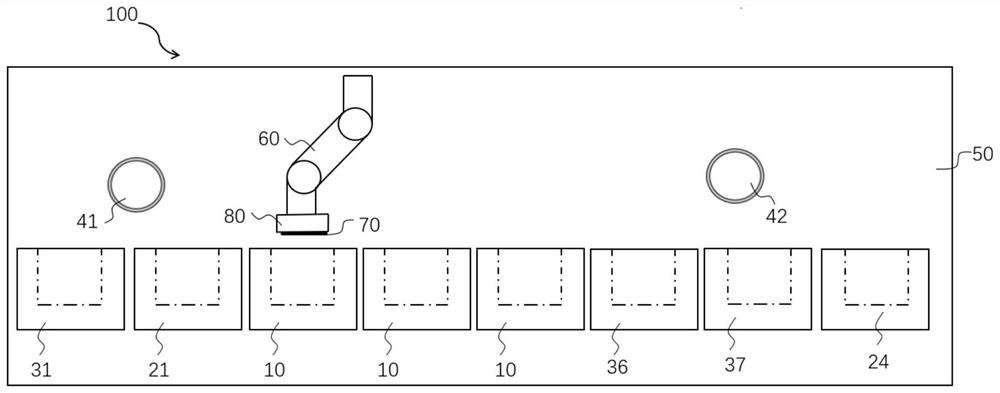

[0088] The present embodiment provides a kind of metal plating equipment 100, comprises a processing chamber 50, is integrated with a plurality of working tanks in the processing chamber 50, and working tank comprises plating tank 10 and process tank, and process tank comprises non-sealed processing process tank and sealed Type treatment process tank. Specifically, such as image 3 As shown, the non-sealed treatment process tank includes a non-sealed pre-treatment process tank 31 and an unsealed post-treatment process tank, and the non-sealed post-treatment process tank includes an EBR treatment process tank 36 and an SRD treatment process tank 37; The process tank includes a sealed pre-treatment process tank 21 and a sealed post-treatment process tank, and the sealed post-treatment process tank includes an annealing treatment process tank 24 .

[0089] The processing chamber 50 is also provided with a moving mechanism 60 and a wafer clamp 80. The wafer clamp 80 is used to cl...

Embodiment 3

[0099] The structure of the metal plating equipment 100 provided by this embodiment is substantially the same as that of Embodiment 2, the difference is that in this embodiment, before the wafer 70 enters the EBR processing tank 36, it is not necessary to unload and unload the wafer from the wafer holder 80, and can Directly driven by the wafer holder 80, it enters the EBR processing tank 36 to perform the EBR processing.

[0100] like Figure 5 and Image 6 As shown, the EBR treatment process tank 36 provided in this embodiment is provided with a spray device 38, and the spray device 38 is provided with a chemical liquid nozzle 381 that is inclined at an angle of 5-15 degrees toward the edge surface of the wafer 70. The spray device 38 is also provided with a number of nitrogen jets 382 and DIW spray ports for jetting nitrogen towards the area within the edge of the wafer 70 .

[0101] After the wafer 70 enters the EBR processing tank 36 with the wafer holder 80, the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com