Graphite fiber sizing method and sizing device

A graphite fiber and sizing agent technology, which is applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve the problems of unsuitable high-modulus brittle graphite fiber, uniform adhesion of unspecified sizing agent, and brittle fiber damage, etc., to achieve threading The operation process is convenient, easy to operate, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

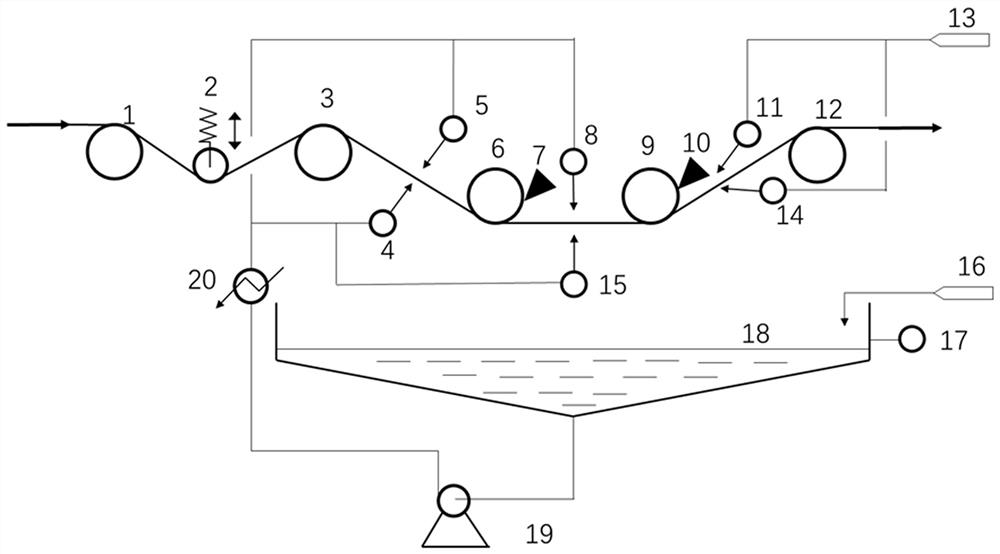

[0067] The graphite fiber beam passes through the drive roller set 1 into the upper weight system, the process parameters in the upper slurry system are: the tension applied by the tension adjustment roller 2 is 400 cn, and the spray velocity of the shower 4, 5 is 1 m / s, the shower 8, 15 Spray velocity is 2 m / s, the material of the cleaning plate 7 and 10 is polytetrafluoroethylene plastic, and the airflow speed of the purge is 3 m / s, and the slurry agent is a water-soluble epoxy resin slurry, concentration of 2.5%. , The upper pulley circulating line heat exchanger uses a hot water heater, and the water temperature is 40 ° C, the upper slurry temperature is 25 ° C. The graphite fiber is introduced from the guide roller 12 and then enters the override drying furnace, from the upper weight drying furnace outlet, the amount of graphite fiber sample is 5 / m, and the bunch is 20%, and the fibrinicity is a grade.

Embodiment 2

[0069] The graphite fiber beam passes through the drive roller set 1 into the upper slurry system, the process parameters in the upper slurry system are: 500 cn applied by the tension adjustment roller 2, the spray velocity of the shower 4, 5 is 1.2 m / s, the shower 8 15 spray velocity is 2 m / s, the material of the cleaning blade 7 and 10 is polytetrafluoroethylene plastic, and the airflow speed of the purge is 3 m / s, the slurry is a water-soluble epoxy resin lace, concentration 2.0 %, The upper pulley circulating line heat exchanger with hot water heater, water temperature is 40 ° C, and the upper slurry temperature is 25 ° C. The graphite fibers were introduced from the guide roller 12 to the upper tide drying furnace, and the amount of graphite fiber sample was taken from the upper weight drying furnace. The amount of graphite sample was 6 / m, the bunch of length was 22%, and the fibrinicity A level.

Embodiment 3

[0071] The graphite fiber beam passes through the drive roller set 1 into the upper weight system, the process parameters in the upper slurry system are: 600 cn applied by the tension adjustment roller 2, the spray velocity of the shower 4, 5 is 1.5 m / s, the shower 8 15 spray speed is 2 m / s, the material of the cleaning plate 7 and 10 is polytetrafluoroethylene plastic, and the airflow speed of the purge is 3 m / s, the cement is a water-soluble epoxy resin lace, concentration 2.5 %, The upper pulley circulating line heat exchanger with hot water heater, water temperature is 40 ° C, and the upper slurry temperature is 25 ° C. The graphite fibers were introduced from the guide roller 12 to enter the upper tap drying furnace, and the amount of graphite fiber sample was taken from the upper tester drying furnace to test the amount of 3 / m, the bundling property was 18%, and the fibrinformation A level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com