Lactobacillus rhamnosus fermented oat milk and preparation method thereof

A technology of Lactobacillus rhamnosus and a production method, which is applied to the field of oat milk fermented by Lactobacillus rhamnosus and its production, can solve problems such as poor survival of beneficial bacteria, contamination by miscellaneous bacteria, short product shelf life and the like, and achieve long storage survival time. , the effect of high viable count and good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

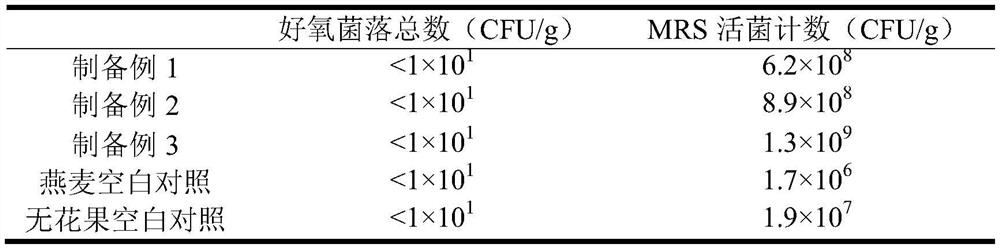

[0076] Example 1 Preparation of Mouse Lactobacillus Oatmeal Milk

[0077] Preparation 1: Weigh 1 parts by weight of oatmeal powder, 1 weight sucrose, 1 weight of lyophilic fig and 7 parts by weight water, stir mix, and homogenate. Cooling at 60 ° C for 1 h, cooking (100 ° C 1H). Refilibrate, homogenate, cooled after vaccination 1.0x10 6 CFU / ml Lactobacillus rhamnosus kf7, 37 ° C is fermented for 8 h.

[0078] Preparation 2: Weigh 1 part weight oatmeal powder, 1 weight sucrose, 2 parts by weight of lyophilic fig and 6 parts by weight of water, stir mix, and homogenate. Cooling at 60 ° C for 1 h, cooking (100 ° C 1H). Refilibrate, homogenate, cooled after vaccination 1.0x10 7 CFU / ml Lactobacillus rhamnosus kf7, 37 ° C is fermented for 8 h.

[0079]Preparation 3: Weigh 3 parts by weight of oatmeal powder, 1 weight sucrose, 2 parts by weight of lyophilic fig and 4 parts by weight of water, stir mix, and homogenate. 70 ° C was held for 1 h, cooked (100 ° C 2H) was cooled. Refilibra...

Embodiment 2

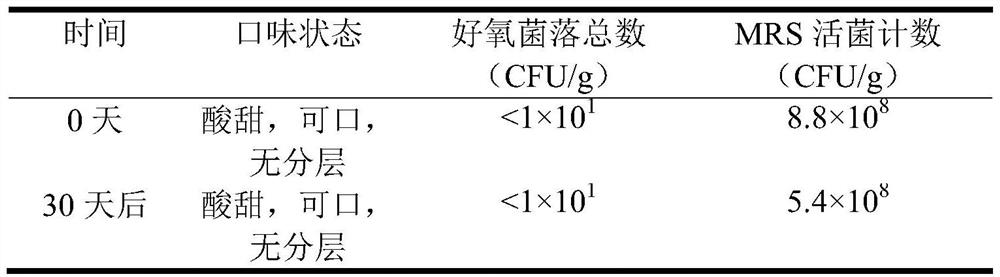

[0085] Example 2 Rats Lactobacillus fermented oatmeal storage survival

[0086] According to the preparation of Example 1, a mouse Li-sugar latex fungus was produced, and after 30 ° C, it was stored at 10 ° C, and the gradient was diluted, and the oxygen contaminite was measured by Lb medium, and MrS medium was counted by MRS Liose. Lactobacillus, the experimental results are shown in Table 2.30 Heat, and the number of live bacteria in the fermented milk obtained by the preparation example 2 of the present invention is not obvious, and it can still reach 5.0 × 10 after 30 days. 8 CFU / G, far higher than lactic acid bacteria beverage hygiene standards (GB 16321-2003) on "Lactic acid bacteria minimum standard: 1.0 × 10 6 Relevant regulations of CFU / g. Therefore, the rats in the fermented dairy in the fermented dairy obtained by the method of the present invention have a high survival rate, in the storage period, the fermented dairy still maintains substantially no state of alcoho...

Embodiment 3

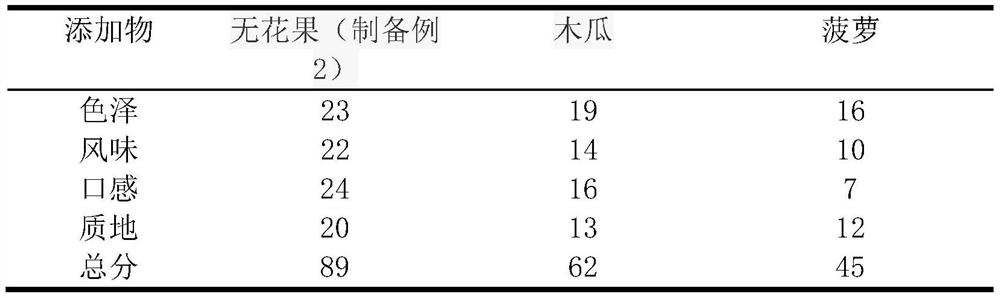

[0090] Example 3 Flavor Contrast Experiment

[0091] The adults in the preparation of Example 1 in Example 1 of the present invention were prepared with papaya, and pineapple alternative to the preparation of fermented emulsion, and the preparation of 2 to produce oatmunctival milk.

[0092] Take the taste test, 50 tested people. Tasting method: Tasting in a manner that is not named; the color, flavor, taste and texture of the above fermented milk products are separately scored, each of which is 25 points, calculating average division and its total score, statistical results record Table 3.

[0093] At the same time, according to the views given to the overall preferences of the product, the statistics are recorded in Table 4 for each item.

[0094] Table 3 taste test

[0095]

[0096] Table 4 Product Pixabay Level Test Results Data Statistics

[0097]

[0098] In terms of product taste, oat fermented milk prepared by the method of prepared by the present invention is higher t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com