High-transparency self-repairing self-adhesion conductive elastic material and preparation method thereof

A self-healing and transparent technology, applied in non-metallic conductors, organic material conductors, etc., can solve the problems of opaque elastomer, low long-term stability, complicated manufacturing process, etc., and achieve the effect of easy adhesion and rapid self-healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Mix 5.584g choline chloride, 5.761g acrylic acid and 0.400g 1-vinylimidazole at 60°C for 1 hour to prepare a polymerizable deep eutectic solvent;

[0036] (2) Add 0.026g photoinitiator 1173 in polymerizable deep eutectic solvent subsequently and obtain the prepolymer solution of mixed liquid after stirring at room temperature, finally the prepared prepolymer solution is subjected to ultraviolet light (light intensity is 13.3mw / cm 2 ) was irradiated for 5s for polymerization to obtain a highly transparent self-healing self-adhesive conductive elastomer.

[0037] After detection, the melting temperature of the polymerizable deep eutectic solvent prepared in step (1) is 1° C., indicating that it is a deep eutectic solvent.

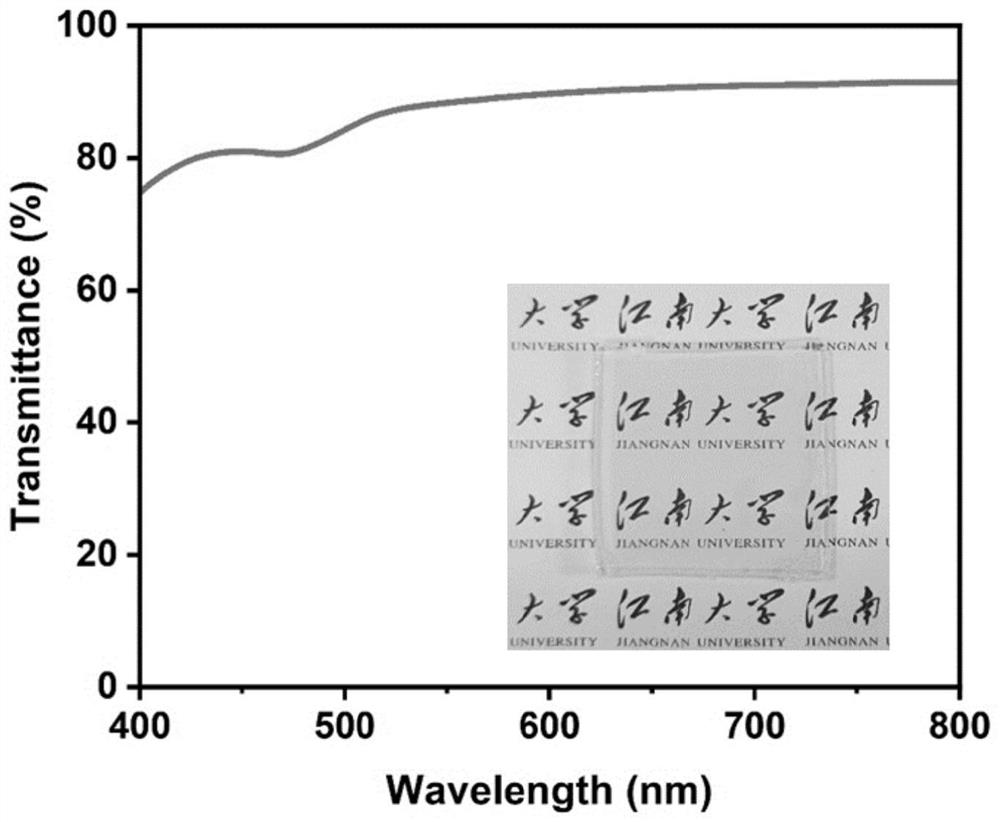

[0038] The ultraviolet spectrum and light transmittance of the highly transparent self-healing self-adhesive conductive elastomer prepared in step (2) are shown in figure 1 , It can be seen that the elastomer prepared by the present invention has...

Embodiment 2

[0043] (1) Mix 6.144g betaine hydrochloride, 6.887g methacrylic acid and 0.400g 1-vinylimidazole at 80°C for 0.5h to prepare a polymerizable deep eutectic solvent;

[0044] (2) Add 0.13g photoinitiator 2959 in polymerizable deep eutectic solvent subsequently and obtain the prepolymer solution of mixed liquid after stirring at room temperature, finally the prepared prepolymer solution is subjected to ultraviolet light (light intensity is 13.3mw / cm 2 ) was irradiated for 15s to obtain a highly transparent self-healing self-adhesive conductive elastomer.

[0045] According to the method of Example 1, it is found that the elastomer prepared in this example also has good light transmittance, electrical conductivity, adhesive performance, mechanical properties, self-repair and self-adhesive properties.

Embodiment 3

[0047] (1) Mix 5.584g choline chloride, 5.761g acrylic acid and 0.400g 2-vinylimidazole at 60°C for 1 hour to prepare a polymerizable deep eutectic solvent;

[0048] (2) Add 0.026g photoinitiator 1173 in polymerizable deep eutectic solvent subsequently and obtain the prepolymer solution of mixed liquid after stirring at room temperature, finally the prepared prepolymer solution is subjected to ultraviolet light (light intensity is 13.3mw / cm 2 ) was irradiated for 10s for polymerization to obtain a highly transparent self-healing self-adhesive conductive elastomer.

[0049] According to the method of Example 1, it is found that the elastomer prepared in this example also has good light transmittance, electrical conductivity, adhesive performance, mechanical properties, self-repair and self-adhesive properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com