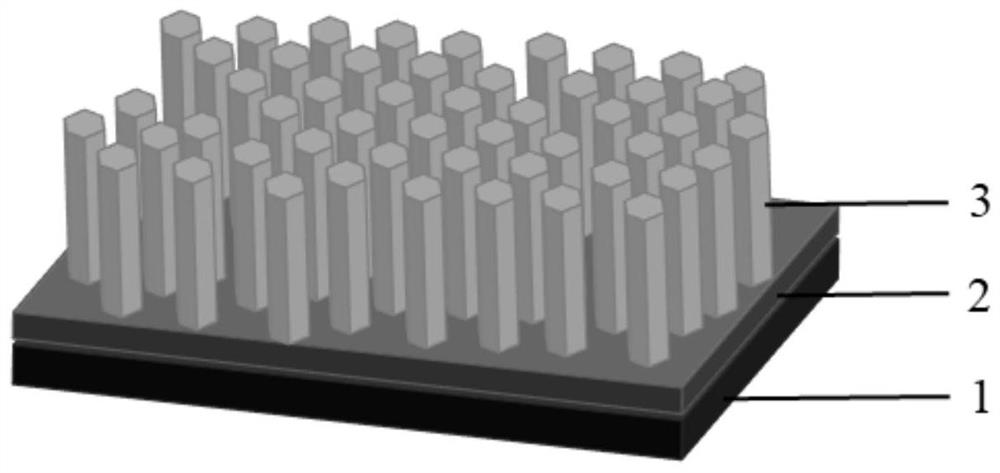

Preparation of array type TiO2/CdS composite electron transport layer and bulk heterojunction solar cell application of array type TiO2/CdS composite electron transport layer

An electron transport layer and solar cell technology, applied in the field of solar cells, achieves the effects of good application prospects, inhibition of charge recombination, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

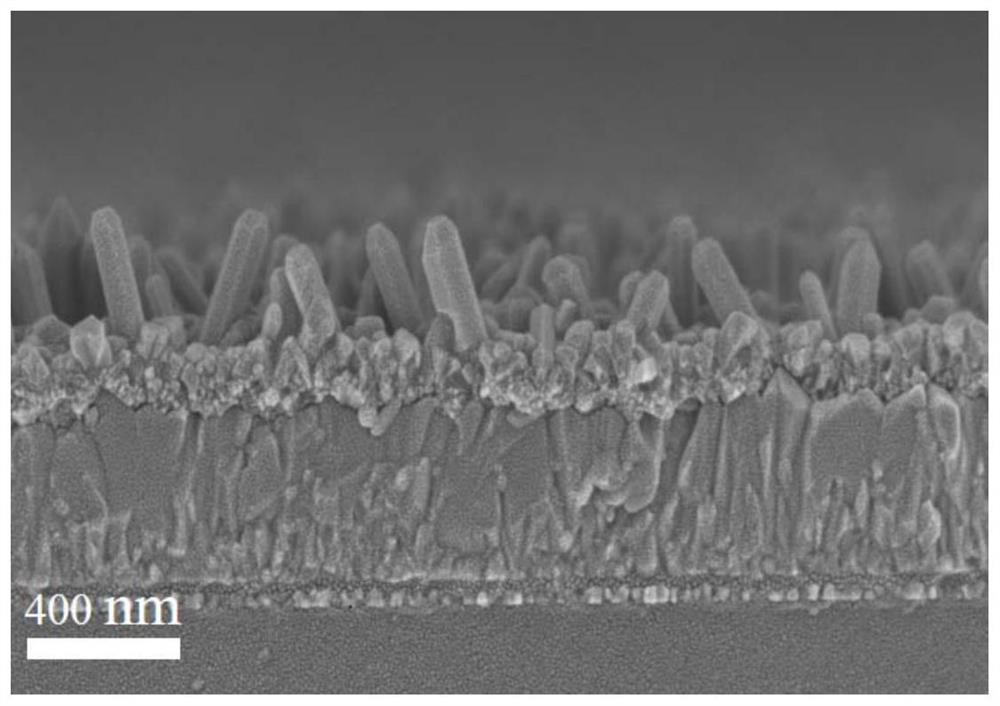

[0045] Preparation of array-based TiO 2 / CdS composite nanostructure electron transport layer perovskite solar cell, the specific steps are as follows:

[0046] 1. Use standard deionized water, IPA and PA to ultrasonically clean the etched FTO glass for 15 minutes, then immediately dry it with a nitrogen gun and then perform UVO treatment for 20 minutes;

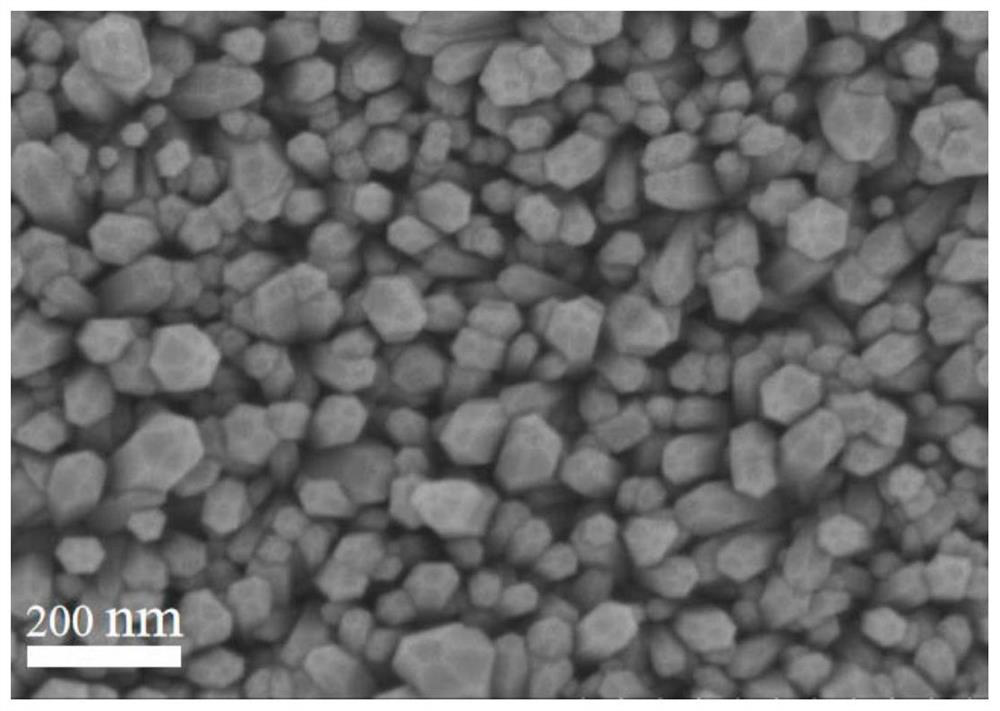

[0047] 2. Take 80 μL of TiO 2 The precursor solution was added dropwise onto the FTO, and spin-coated at a speed of 500rpm for 3s, and then spin-coated at a speed of 2000rpm for 30s. After the spin-coating, it was annealed on a heating table at 135°C for 10min, and finally placed in a muffle furnace. Sinter at 500°C for 30 minutes to form a dense layer;

[0048] 3. Mix 0.01M Cd(NO 3 ) 2 4H 2 O, 0.03M thiourea and 0.006M glutathione (GSH) were sequentially added to 80 mL of deionized water, and stirred at room temperature for 15 min;

[0049] 4. Will contain TiO 2 The FTO of the dense layer was immersed in the solution...

Embodiment 2

[0055] Unlike Example 1, the hydrothermal heat in step 4 is 90min, and the prepared MAPbI 3 The perovskite solar cell has an efficiency of 18.72%.

Embodiment 3

[0057] Different from Example 1, the hydrothermal heat in step 4 is 100min, and the prepared MAPbI 3 The perovskite solar cell has an efficiency of 19.01%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com