Thermal protective agent of HMB, application of thermal protective agent, HMB derivative and application of HMB derivative

A heat protectant and derivative technology, which is applied in the fields of non-active ingredients medical preparations, food science, drug combinations, etc., can solve the problems of unsolved HMB deterioration, yellowing and odor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

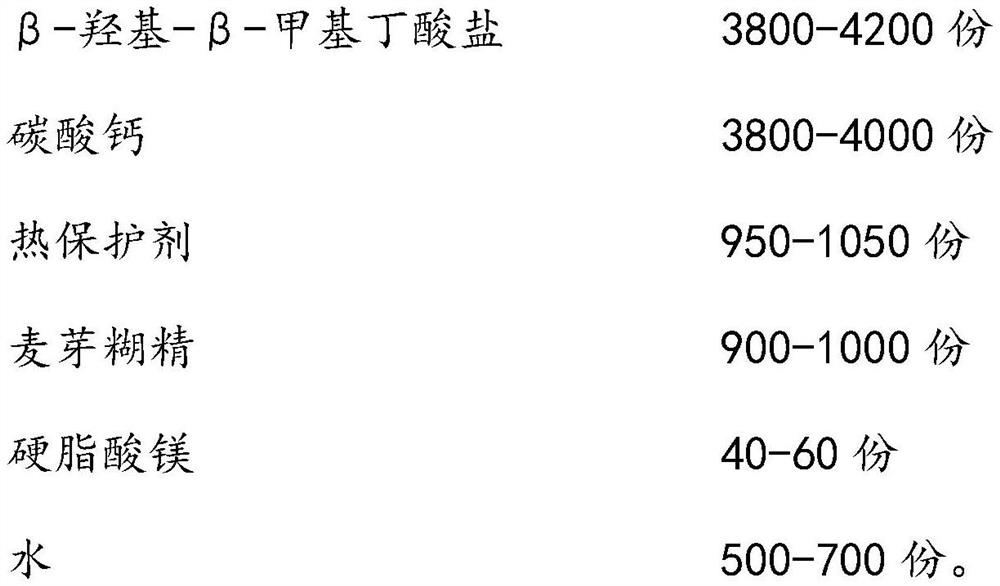

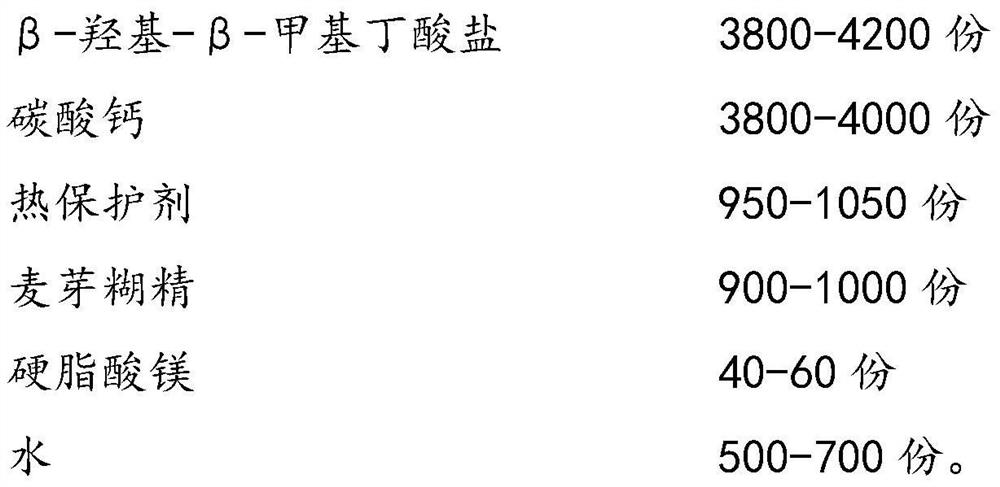

[0037] β-Hydroxy-β-methylbutyrate is currently mostly prepared in the form of tablets, and heating steps such as drying in the wet granulation process are likely to denature HMB. In some specific embodiments of the present invention, when the composition is a tablet, it includes the following parts by weight of raw materials: 3800-4200 parts of β-hydroxy-β-methylbutyrate, calcium carbonate 3800-4000 parts, 950-1050 parts of heat protection agent, 900-1000 parts of maltodextrin, 40-60 parts of magnesium stearate and 500-700 parts of water; preferably, the raw materials include β-hydroxy-β-formazan 3950-4050 parts of calcium butyrate, 3950-4050 parts of calcium carbonate, 980-1030 parts of magnesium malate, 920-1000 parts of maltodextrin, 45-55 parts of magnesium stearate and 550-650 parts of water. The preparation method of above-mentioned composition comprises the steps:

[0038] (4) pulverizing the raw materials except magnesium stearate and water, mixing the pulverized raw ...

Embodiment 1

[0050] Example 1 Composition Tablet 1 Containing HMB and Heat Stabilizer

[0051] The composition comprises the following raw materials: 4000g of calcium β-hydroxy-β-methylbutyrate, 4000g of calcium carbonate, 1000g of magnesium malate, 950g of maltodextrin, 50g of magnesium stearate and 600g of water.

[0052] (1) Use a 40-mesh sieve to sieve β-hydroxy-β-methyl calcium butyrate fine powder, calcium carbonate fine powder, magnesium malate fine powder, malt paste fine powder, magnesium stearate with D90≤380 microns fine powder for use;

[0053] (2) Add 4000g of the above-mentioned β-hydroxy-β-methyl calcium butyrate fine powder, 4000g of calcium carbonate fine powder, 1000g of magnesium malate fine powder, 950g of malt paste fine powder, 50g of magnesium stearate fine powder, and 600g of water In a high-speed mixer, the mixing time is 10 minutes, and the mixing temperature is 35°C to obtain a soft material;

[0054] (3) the above-mentioned soft materials are granulated by a w...

Embodiment 2

[0058] Example 2 Composition Tablet 2 Containing HMB and Heat Stabilizer

[0059] The composition comprises the following raw materials: 3950g of calcium β-hydroxy-β-methylbutyrate, 3950g of calcium carbonate, 950g of calcium malate, 900g of maltodextrin, 40g of magnesium stearate and 500g of water.

[0060] (1) Use a 40-mesh sieve to sieve β-hydroxy-β-methyl calcium butyrate fine powder, calcium carbonate fine powder, calcium malate fine powder, malt paste fine powder, magnesium stearate with D90≤380 microns fine powder for use;

[0061] (2) 3950g of the above-mentioned β-hydroxy-β-methyl calcium butyrate fine powder, 3950g of calcium carbonate fine powder, 950g of L-malic acid fine powder, 900g of malt paste fine powder, 40g of magnesium stearate fine powder, and 500g of water Add it to a high-speed mixer, mix for 5 minutes, and mix at a temperature of 25°C to make a soft material;

[0062] (3) the above-mentioned soft materials are granulated by a wet granulator, and 10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com