Preparation method of Cu-MOFs loaded multifunctional cotton fabric

A cotton fabric, multi-functional technology, applied in plant fibers, textiles and papermaking, fiber processing and other directions, can solve the problem of long process time, and achieve the effect of broad application prospects, simple equipment and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

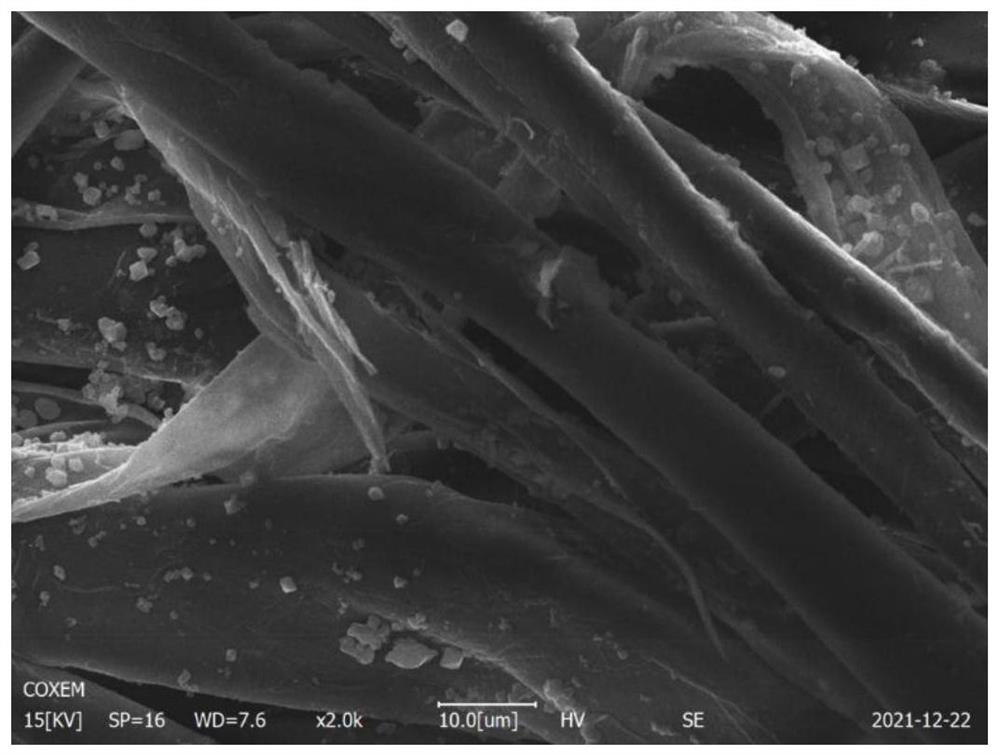

[0025] refer to figure 1 , a method for preparing a multifunctional cotton fabric loaded with Cu-MOFs, the specific steps are as follows:

[0026] Step 1, adopt butane tetracarboxylic acid to modify cotton fabric: after cotton fabric is soaked in the aqueous solution that contains 4wt% butane tetracarboxylic acid and 4wt% sodium hypophosphite 5min, roll and press with paddle car, two Dip twice. The padded cotton fabric was prebaked at 100°C for 3 minutes, and finally baked at 180°C for 3 minutes to obtain a modified cotton fabric.

[0027] Step 2: Load Cu-MOFs onto cotton fabrics by layer-by-layer assembly method: configure 0.02M copper nitrate trihydrate aqueous solution A, and immerse the modified cotton fabrics in solution A for 10 min. Then add 0.02M nanometer ZnO dispersion liquid into the solution A, stir rapidly to form the hydroxyl double salt solution B, and continue to soak the modified cotton fabric in the solution B for 10 minutes before taking it out. With etha...

Embodiment 2

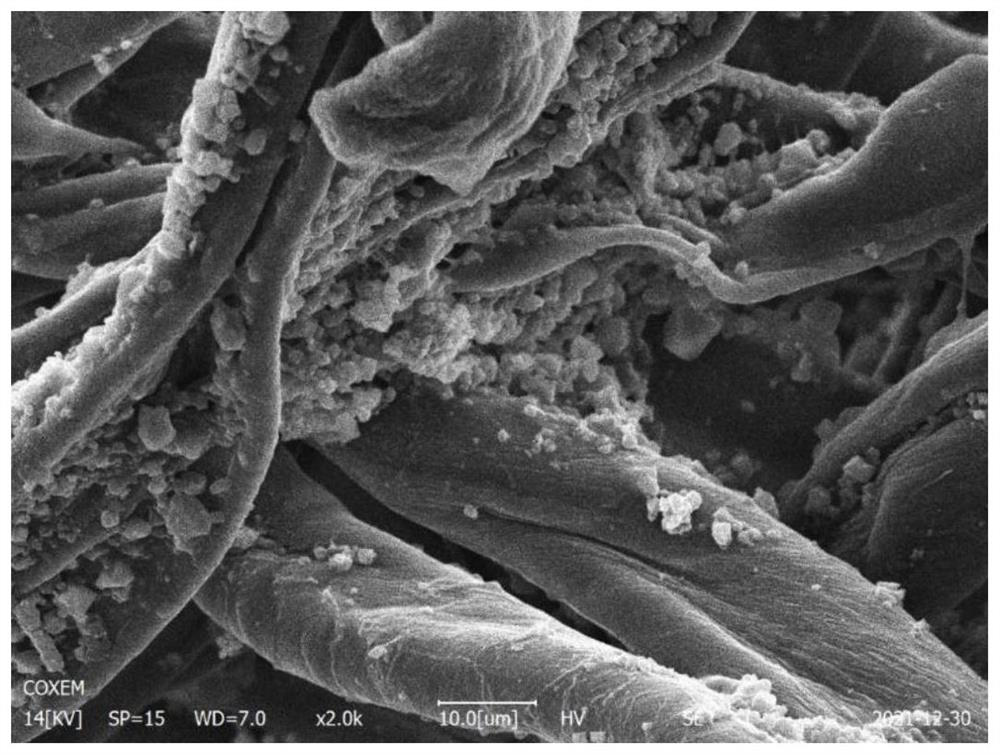

[0029] refer to figure 2 , a method for preparing a multifunctional cotton fabric loaded with Cu-MOFs, the specific steps are as follows:

[0030] Step 1, using citric acid to modify the cotton fabric: immerse the cotton fabric in an aqueous solution containing 4wt% citric acid and 4wt% sodium hypophosphite for 5 minutes, and then use a paddle car to perform rolling, two dipping and two rolling. The padded cotton fabric was prebaked at 100°C for 3 minutes, and finally baked at 180°C for 3 minutes to obtain a modified cotton fabric.

[0031] Step 2: Load Cu-MOFs onto cotton fabrics by layer-by-layer assembly method: prepare 0.1M copper sulfate pentahydrate aqueous solution A, and immerse the modified cotton fabrics in solution A for 10 min. Then add 0.1M nanometer ZnO dispersion liquid into solution A, stir rapidly to form hydroxyl double salt solution B, and the modified cotton fabric is continuously soaked in solution B for 10 minutes and then taken out. With ethanol and N...

Embodiment 3

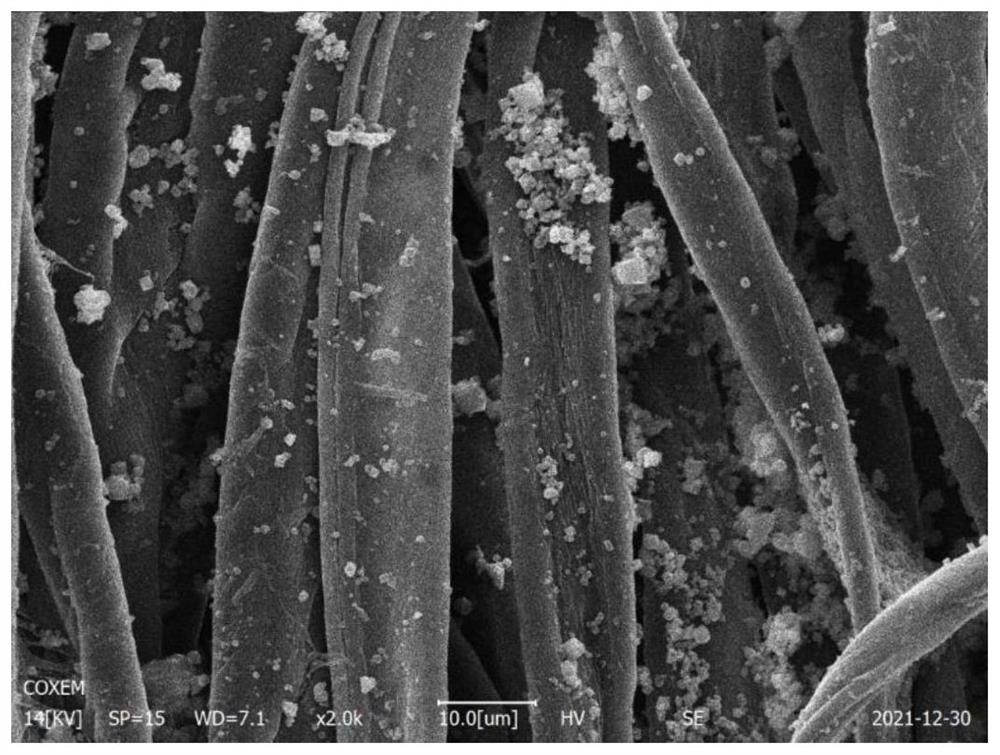

[0033] refer to image 3 , a method for preparing a multifunctional cotton fabric loaded with Cu-MOFs, the specific steps are as follows:

[0034] Step 1, adopt butane tetracarboxylic acid to modify cotton fabric: after cotton fabric is soaked in the aqueous solution that contains 4wt% butane tetracarboxylic acid and 4wt% sodium hypophosphite 5min, roll and press with paddle car, two Dip twice. The padded cotton fabric was prebaked at 100°C for 3 minutes, and finally baked at 180°C for 3 minutes to obtain a modified cotton fabric.

[0035]Step 2: Load Cu-MOFs onto cotton fabrics by layer-by-layer assembly method: configure 0.05M copper chloride dihydrate aqueous solution A, and immerse the modified cotton fabrics in solution A for 10 min. Then add 0.05M nanometer ZnO dispersion liquid into the solution A, stir rapidly to form the hydroxyl double salt solution B, and continue to soak the modified cotton fabric in the solution B for 10 minutes before taking it out. With ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com