Rotary chemiluminescent protein chip

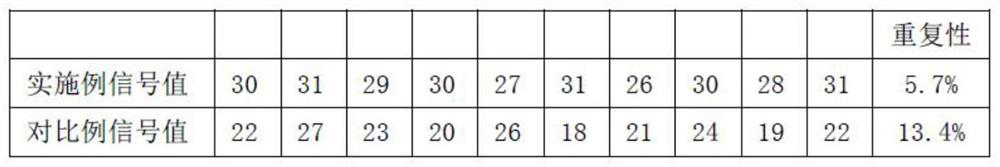

A chemiluminescence and protein chip technology, which is applied in chemiluminescence/bioluminescence, analysis through chemical reactions of materials, scientific instruments, etc., can solve the problem that liquid cannot be effectively removed, the repeatability of protein chips is not high, and infiltration Uncontrollable time and other issues, to achieve the effect of low assembly difficulty, improved repeatability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

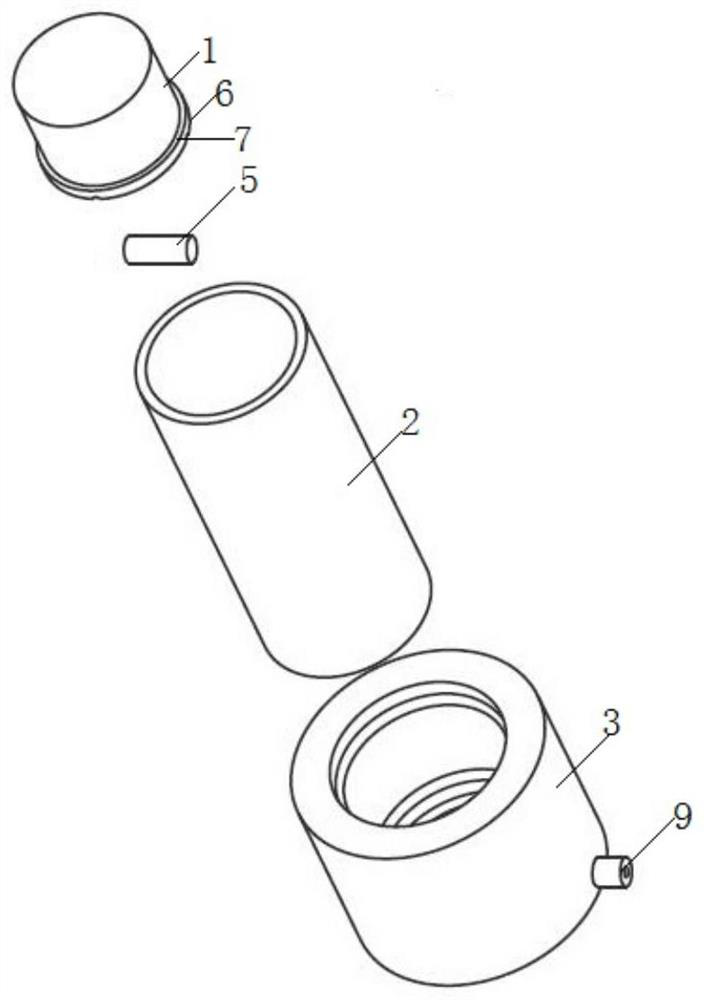

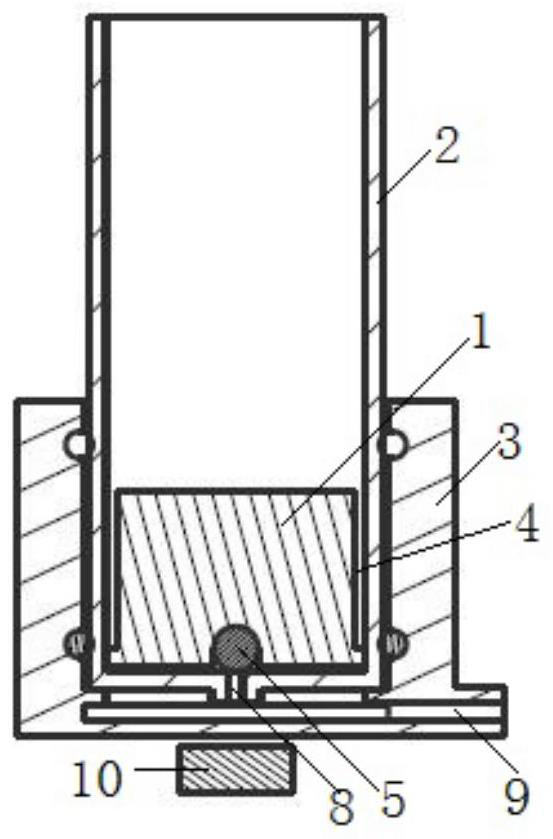

[0035] (1) Stick the porous carrier 4 coated with the Helicobacter pylori antigen microarray (nitrocellulose membrane is used as the carrier in this embodiment) to the outer ring of the cylindrical rotor 1 with self-adhesive or other adhesive film On the surface, the rotor 1 is placed in a cylindrical cuvette 2 made of transparent organic glass;

[0036] (2) Add 200 μL of the sample to be tested into the cuvette 2 at room temperature;

[0037] (3) Place the cuvette 2 on the base 3 and place the base 3 on the magnetic stirrer 10, turn on the magnetic stirrer 10, the reaction time is 10min, the rotating speed is 200r / min, the rotor 1 in the cuvette 2 starts to rotate , to drive the nitrocellulose diaphragm on the rotor 1 to rotate together;

[0038] (4) After the reaction is completed, the peristaltic pump is turned on, and the excess liquid in the cuvette 2 is sucked out by the peristaltic pump through the drain pipe 9 at the bottom of the cuvette 2;

[0039] (5) Add 300 μL o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com