Gel candy containing herba brassicae rubrae, rose and angelica sinensis oil and preparation method of gel candy

A technology for oil gel candy and gel candy, which is applied in the field of star rue, rose and angelica oil gel candy and its preparation field, can solve the problems of lack of beauty function, unable to meet the demand of gel candy, poor effect and the like, and achieves the Better absorption, smoother taste and richer nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Astragalus rose angelica oil gel candy, the gel candy is composed of the following ingredients by weight percentage: 10% xylitol, 8% edible gelatin, 13% perilla seed oil, 15% peony seed oil, 8% Milk thistle seed oil, 8% ingot maple seed oil, 6% jujube seed oil, 6% wolfberry seed oil, 6% rose oil, 10% angelica root oil, 2% rose pollen, 1% raspberry powder, 1% dandelion Powder, 5% glycerin, 1% solvent.

[0034] Further, the rose pollen is double red rose pollen.

[0035] Further, the solvent is purified water.

[0036] Xylitol: the sweetness is equivalent to that of sucrose. When dissolved in water, it can absorb a large amount of heat. It is the one with the largest heat absorption value among all sugar alcohol sweeteners. Therefore, when eaten in solid form, it will produce a pleasant cooling sensation in the mouth , the metabolism is not regulated by insulin, and the metabolism is complete in the human body, which can be used as a heat source for diabetics.

[0037]...

Embodiment 2

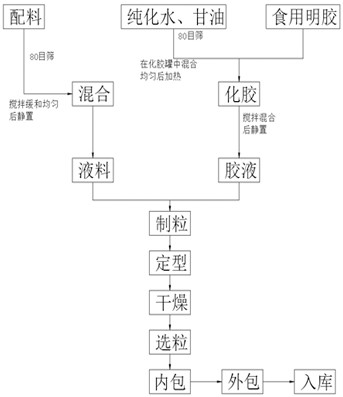

[0051] refer to figure 1 Shown, the present invention also provides the equipment method of astral grass rose angelica oil gel candy, comprising the following steps:

[0052] (1) Crushing and sieving: sugar alcohol, perilla seed oil, peony seed oil, silymarin seed oil, ingot maple seed oil, jujube seed oil, wolfberry seed oil, rose oil, angelica root oil, rose pollen, mulberry The raw and auxiliary materials of basin powder and dandelion powder are respectively crushed by a pulverizer, passed through an 80-mesh sieve, put into clean stainless steel containers, weighed and labeled. The name, batch number, weight, date, operator and Reviewer's name.

[0053] (2) Weighing: According to the batch weighing step (1), the raw and auxiliary materials required are placed in another clean stainless steel container, and a label is attached to the outside of the stainless steel container. The label is filled with name, batch number, weight, date, Name of operator and reviewer.

[0054] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com