Functional nano-zinc oxide modified polycarbonate sheet and preparation method thereof

A technology of nano-zinc oxide and polycarbonate, which is applied in the field of polycarbonate, can solve the problems of poor mechanical properties such as impact strength of polycarbonate sheets, and achieve the effect of enhancing functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

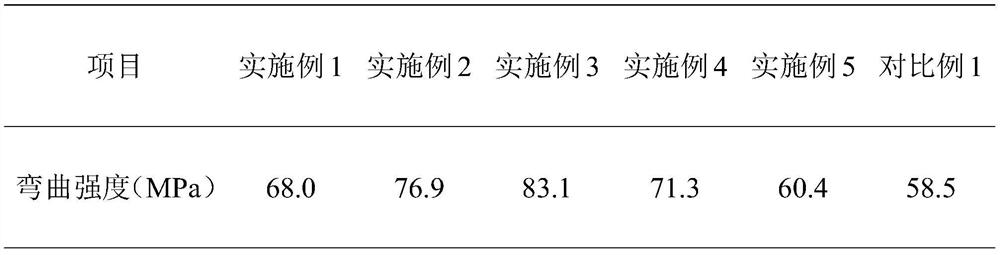

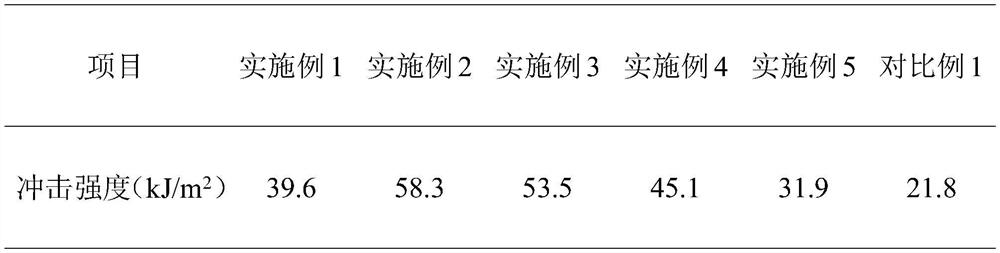

Examples

preparation example Construction

[0022] In order to achieve the above object, the present invention provides the following specific implementation methods and examples: a functional nano-zinc oxide modified polycarbonate sheet, the preparation method comprising the following steps:

[0023] (1) Add N,N-dimethylformamide solvent and nano-zinc oxide to the reactor, after ultrasonic dispersion is uniform, continue to add 2-isocyanatoethyl methacrylate and dibutyltin dilaurate, wherein The mass ratio of N,N-dimethylformamide solvent, nano-zinc oxide, 2-isocyanatoethyl methacrylate and dibutyltin dilaurate is 200-550:10:6-15:0.02-0.06, Stir and mix evenly, transfer to an oil bath, stir and react at a constant temperature of 60-80°C for 6-18h, centrifuge, wash and dry after the reaction to obtain alkenylated zinc oxide;

[0024] (2) Add absolute ethanol solvent and alkenyl zinc oxide to the reactor, after ultrasonic dispersion for 20-40min, continue to add tris(2-aminoethyl)amine, wherein absolute ethanol solvent, ...

Embodiment 1

[0028] (1) Add 110mL of N,N-dimethylformamide solvent and 5g of nano-zinc oxide to the reactor, after ultrasonic dispersion is uniform, continue to add 3g of 2-isocyanatoethyl methacrylate and 0.01g of di Dibutyltin laurate, stirred and mixed evenly, transferred to an oil bath, stirred and reacted at a constant temperature of 60°C for 6 hours, after the reaction was completed, centrifuged, washed and dried to obtain alkenyl zinc oxide;

[0029] (2) Add 160mL of absolute ethanol solvent and 5g of alkenyl zinc oxide into the reactor, after ultrasonic dispersion for 20min, continue to add 1.25g of tris(2-aminoethyl)amine, mix well and transfer to the oil bath, React at a constant temperature of 30°C for 36 hours, precipitate after the reaction, filter with suction, wash and dry to obtain aminated zinc oxide;

[0030] (3) Add 210mL of xylene solvent and 5g of aminated zinc oxide to the reactor, ultrasonically disperse until completely dissolved, then continue to add 2g of maleic a...

Embodiment 2

[0033](1) Add 160mL of N,N-dimethylformamide solvent and 5g of nano-zinc oxide to the reactor, after ultrasonic dispersion is uniform, continue to add 4g of 2-isocyanatoethyl methacrylate and 0.015g of di Dibutyltin laurate, stirred and mixed evenly, transferred to an oil bath, stirred and reacted at a constant temperature of 65°C for 8 hours, after the reaction was completed, centrifuged, washed and dried to obtain alkenyl zinc oxide;

[0034] (2) Add 200mL of absolute ethanol solvent and 5g of alkenyl zinc oxide to the reactor, after ultrasonic dispersion for 25min, continue to add 1.8g of tris(2-aminoethyl)amine, mix well and transfer to the oil bath, React at a constant temperature of 35°C for 48 hours, precipitate after the reaction, filter with suction, wash and dry to obtain aminated zinc oxide;

[0035] (3) Add 260mL of xylene solvent and 5g of aminated zinc oxide into the reactor, ultrasonically disperse until completely dissolved, then continue to add 2.5g of maleic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com