Preparation method of biscuits

A technology for biscuits and flour, applied in the preparation of biscuits, the application field of glutaminase in increasing the crispness of biscuits and/or increasing the umami taste of biscuits, which can solve the problems affecting the flavor of flour products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

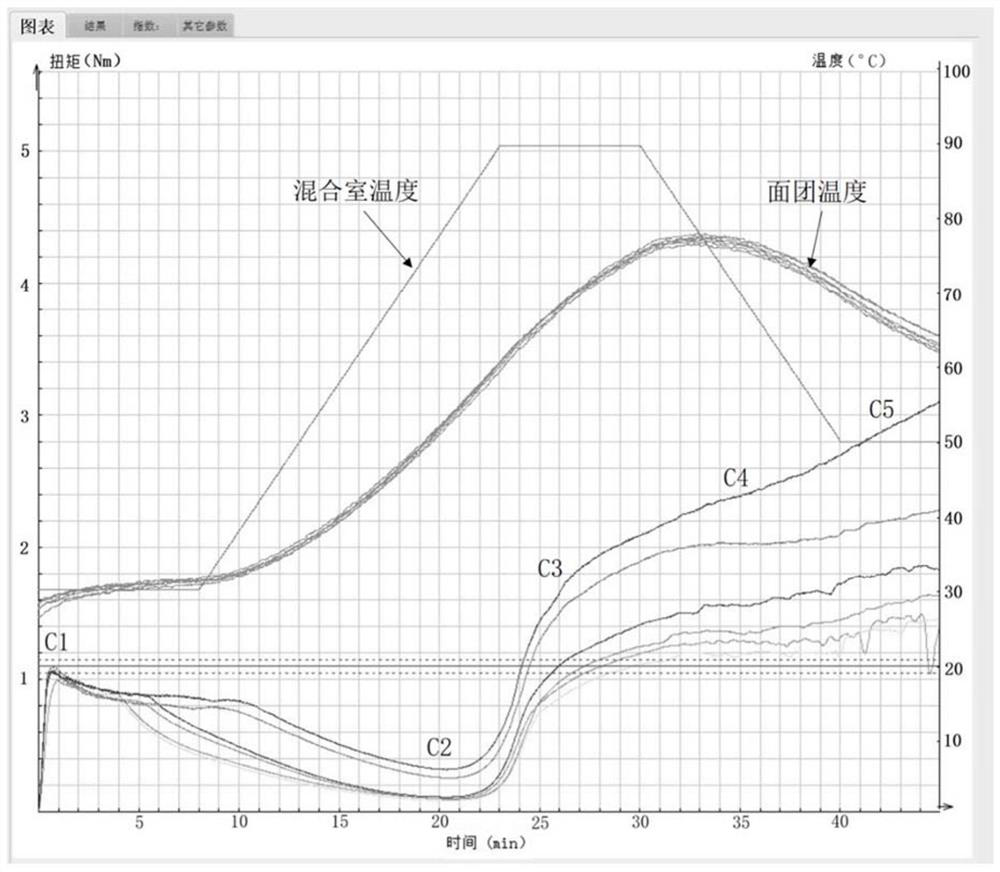

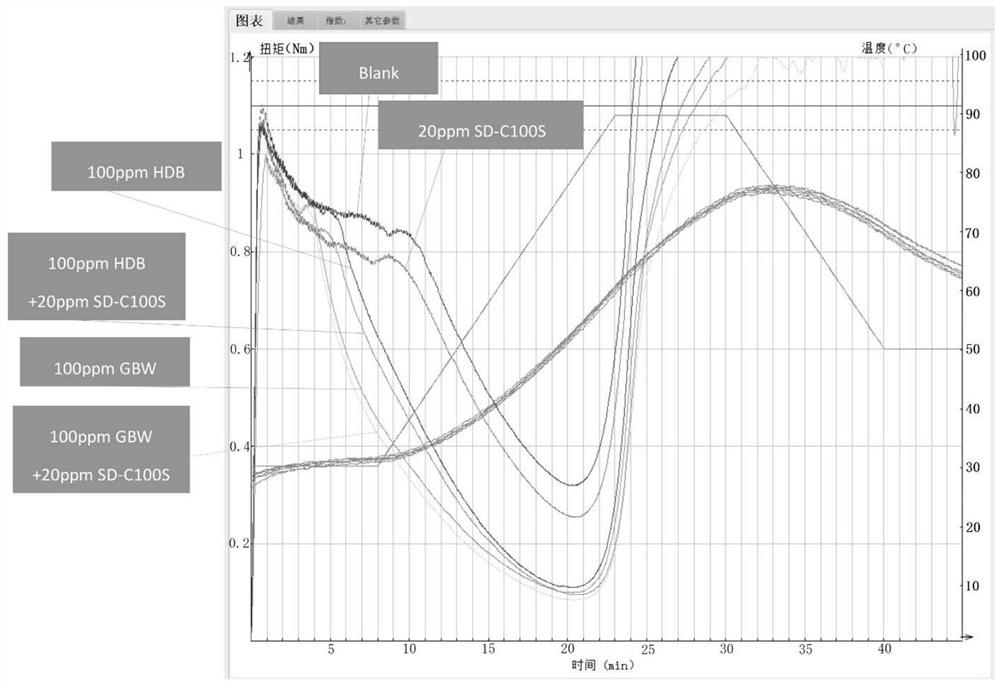

[0037] Example 1: Gluten-weakening effect of glutaminase

[0038] In this experiment, the gluten-weakening effect of glutaminase was determined according to the following materials and methods:

[0039] 1) Experimental materials

[0040] Experimental wheat flour: high-gluten flour without additives.

[0041] Enzyme preparation: used in the experiment HDB, GBW was purchased from DSM, and SD-C100S was purchased from Amano Enzyme Co., Ltd. in, HDB and GBW is a special enzyme preparation for biscuit dough, the former contains protease and xylanase, and the latter contains protease. SD-C100S is a glutaminase preparation derived from Bacillus amyloliquefaciens.

[0042] Instruments and equipment: EM10 standard oven, purchased from Chopin Technologies, France; Mixolab mixing tester, purchased from Chopin Technologies, France.

[0043] 2) Experimental method

[0044] a) Determination of moisture content in flour

[0045] The moisture content of flour is determined acco...

Embodiment 2

[0067] Embodiment 2: the preparation of soda cracker

[0068] Prepare soda crackers as follows:

[0069] 1) Flour mixing for the first time: 135g of the 300g of test flour was added to 2g of fresh yeast liquid that had been melted with 65g of warm water in advance, and stirred in a Hobart dough mixer at a slow speed for 3 minutes to form a dough.

[0070] 2) First fermentation: Put the prepared dough into a plastic box, put it into a temperature-adjusting and humidity-adjusting box for fermentation, the temperature is about 38°C, the relative humidity is about 70%, and the fermentation time is 2 hours.

[0071] 3) The second powder adjustment: Add 135g flour, 40.5g fat, 1.1g maltose syrup, 12.5g milk powder, 1.25g refined salt, 1.0g NaHCO to the dough fermented for the first time 3 , 0.7gNH 4 HCO 3 , and 30g of warm water and other auxiliary materials, mix thoroughly, and stir at a slow speed for 5 minutes.

[0072] 4) Second fermentation: Put the dough into a temperatur...

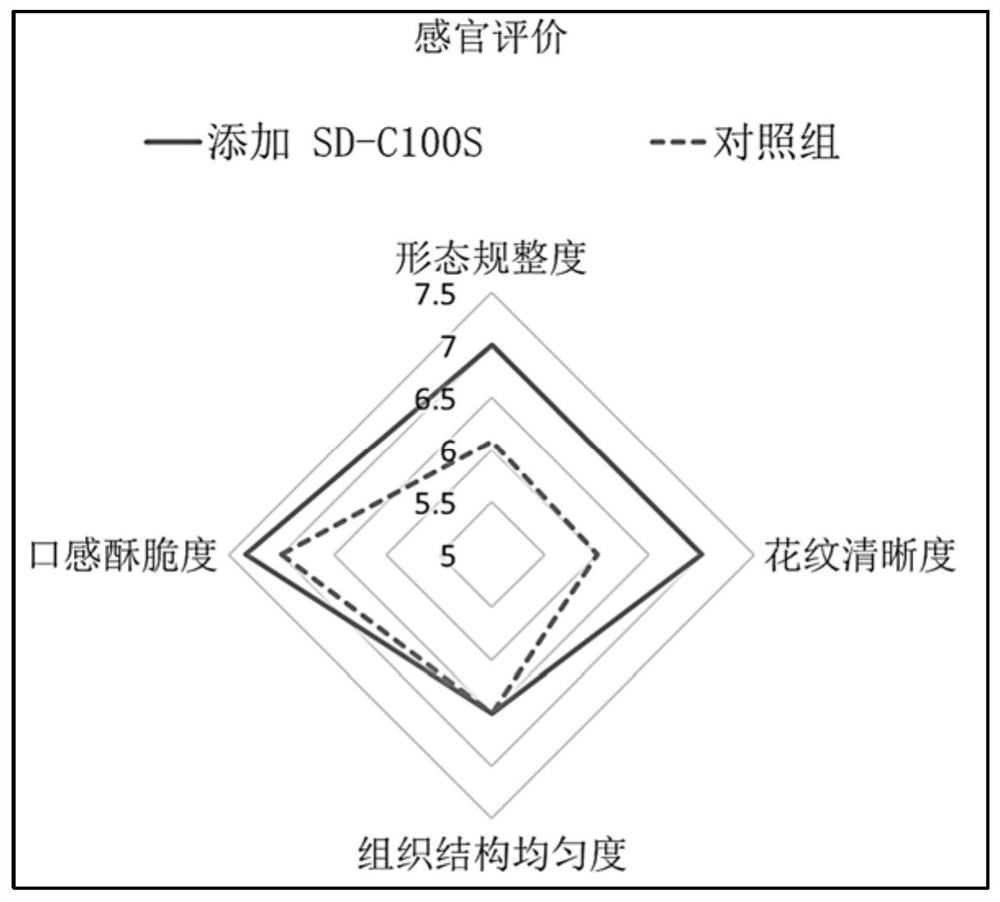

Embodiment 3

[0079] Embodiment 3: the preparation of short biscuit

[0080] 1) Weigh 85.5g of white granulated sugar and add about 15ml of water. Heat to dissolve, cool to about 30°C, and add 13.8g of maltose.

[0081] 2) Heat and melt 45g of shortening and 6g of cream together, then cool to about 30°C, and add 0.012g of citric acid therein.

[0082]3) Dissolve 0.21g of the weighed baking soda in 5ml of cold water, and dissolve 0.9g of the weighed table salt and 0.9g of ammonium bicarbonate in 5ml of cold water.

[0083] 4) Mix the oil and sugar together, stir for 10 seconds with a Hobart dough mixer at low speed, then add 50g of eggs and stir until uniform (about 20 seconds at medium speed).

[0084] 5) Then add sodium bicarbonate solution, stir evenly at low speed, then add the mixture of salt and ammonium bicarbonate, stir at low speed until uniform.

[0085] 6) Mix all auxiliary materials (except milk powder) evenly for about 1 minute.

[0086] 7) Mix 13.8g of milk powder and 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com