Method for removing organic pollutants by activating persulfate with diatomite composite material loaded with iron and manganese

A technology for activating persulfate and organic pollutants, applied in the field of environmental remediation, can solve the problems of serious energy consumption, difficult to recycle, uneconomical, etc., and achieve the effects of strong activation performance, low cost, enhanced load capacity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

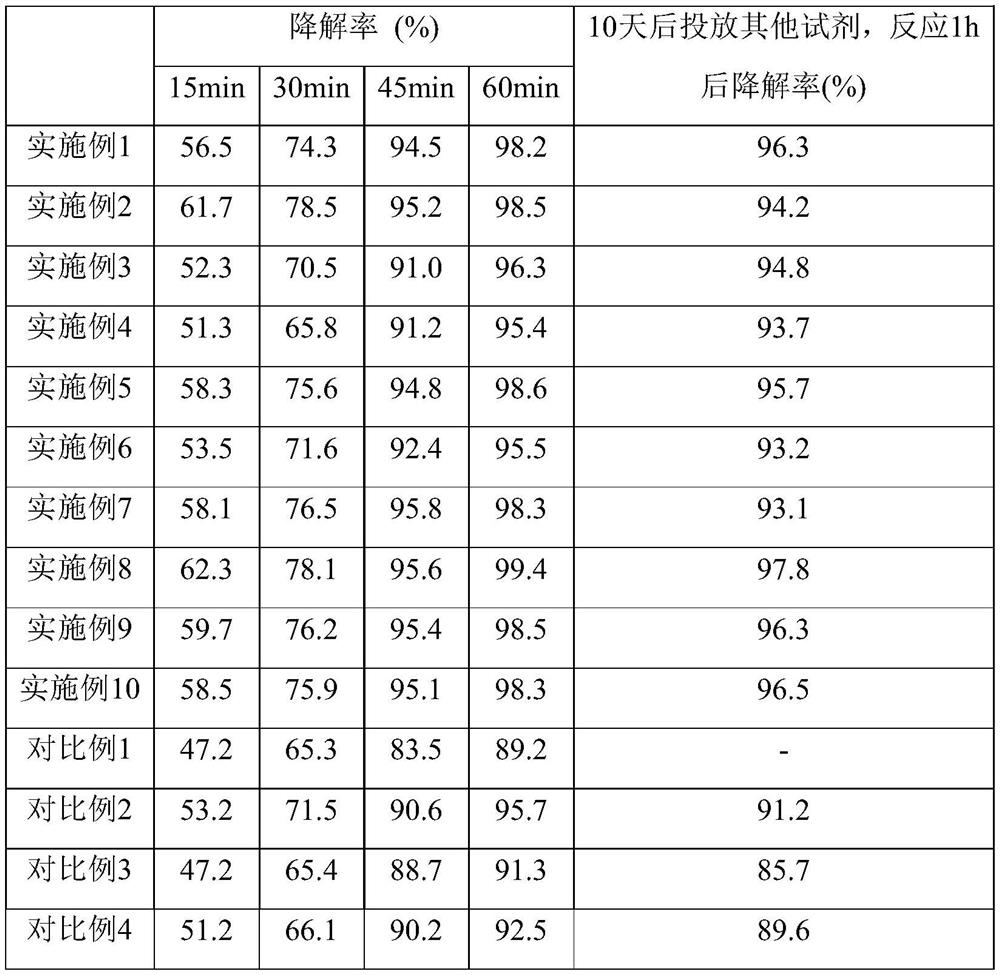

Examples

Embodiment 1

[0037](S1) 100 parts of diatomite were soaked in 10wt% dilute hydrochloric acid for 1 hour under stirring conditions, centrifuged, and dried to complete the pretreatment of diatomite. The pretreated diatomite was impregnated in 200 parts of In the ethanol solution of 2wt% KH-580, soak for 5h, take out, wash with water, dry to obtain the diatomite modified by mercaptosilane coupling agent; the modified diatomite is impregnated in 300 parts of Fe(NO 3 ) 2 and MnCl 2 In the mixed solution of Fe(NO 3 ) 2 The molar concentration is 0.2mol / L, MnCl 2 The molar concentration is 0.04mol / L, add 100 parts of 30wt% ammonia water, stir to form a slurry, after drying, wash twice with deionized water, then wash twice with ethanol, dry, grind and sieve to obtain an average particle size of about 120 μm diatomite composite material loaded with iron and manganese;

[0038] (S2) In a brown reagent bottle with 100 mL of 200 μM chlorobenzene, 1 g of the diatomite composite material loaded wit...

Embodiment 2

[0040] Other conditions and operation are identical with embodiment 1, difference is in step (S1), Fe(NO 3 ) 2 The molar concentration is 0.24mol / L, MnCl 2 The molar concentration is 0.03mol / L.

Embodiment 3

[0042] Other conditions and operation are identical with embodiment 1, difference is in step (S1), Fe(NO 3 ) 2 The molar concentration is 0.24mol / L, MnCl 2 The molar concentration is 0.02mol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com