Abradable sealing composite coating material and preparation method thereof

A composite coating and abrasion technology, which is applied in the field of aero-engines, can solve problems such as cracking and peeling, frequent repairs of coatings, and affecting the safety of the engine, so as to reduce thermal stress, avoid high-temperature oxidation, and have good resistance to water vapor corrosion and corrosion resistance. The effect of oxidation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

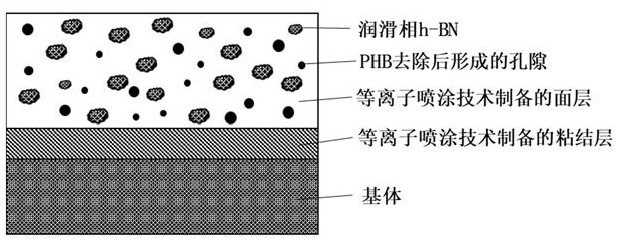

[0037] Preparation of the bonding layer. Specifically, the Si-containing bonding layer is prepared on the surface of the base material, that is, the plasma spraying method is used, and the silicon powder is used as the raw material to spray the silicon coating. The parameters of the plasma spraying process include: current 300-700A, argon gas flow rate 40 ~60slm, hydrogen flow rate 5~15slm, spraying power 30~50kW, spraying distance 100~300mm, powder feeding rate 10~35r / min. The thickness of the adhesive layer is 50 to 500 μm, preferably 50 to 200 μm. The SiC bonding layer can also be prepared. On the basis of preparing the silicon coating, the SiC coating can be formed by heat treatment at a high temperature of 1400-1800 °C for 1-4 hours in an atmosphere protection.

[0038] Preparation of toppings. The powder used for the wearable sealing surface layer is sprayed on the substrate with the bonding layer by using the plasma spraying method. Among them, the parameters of the ...

Embodiment 1

[0044] Step 1: Sandblasting the surface of the C / SiC substrate with a blasting pressure of 0.2 MPa to obtain a surface pretreated substrate.

[0045] Step 2: Prepare a Si layer on the surface of the pretreated substrate by using a plasma spraying method, and the spraying process parameters are shown in Table 2.

[0046] Table 2 Process parameters of plasma sprayed Si coating

[0047] Plasma gas Ar 38slpm Powder carrier gas Ar 2.5 slpm electric current 500A Plasma gas H 2

[0048] Step 3: heat-treat the substrate with the Si coating in a vacuum atmosphere furnace at 1550° C. for 3 hours, so that the Si layer reacts in situ to form a SiC bonding layer.

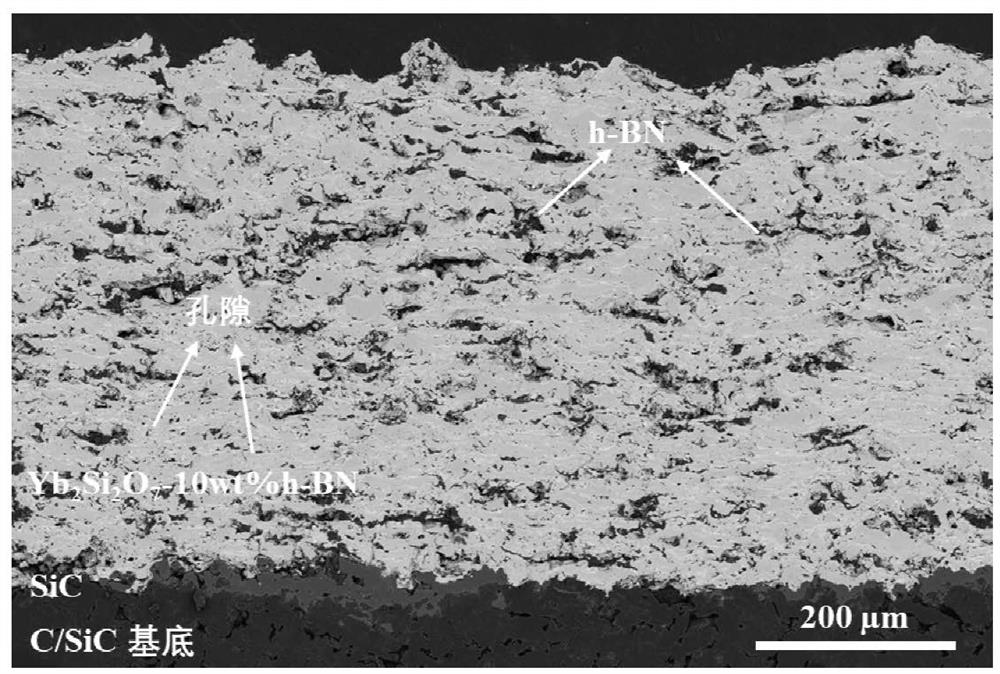

[0049] Step 4: Prepare Yb on the surface of the SiC bonding layer by plasma spraying 2 Si 2 o 7 -10wt.% h-BN composite coating, the spraying process parameters are shown in Table 3.

[0050] Table 3 Plasma sprayed Yb 2 Si 2 o 7 Process parameters of -10 wt% h-BN coating

[0051] Plasma...

Embodiment 2

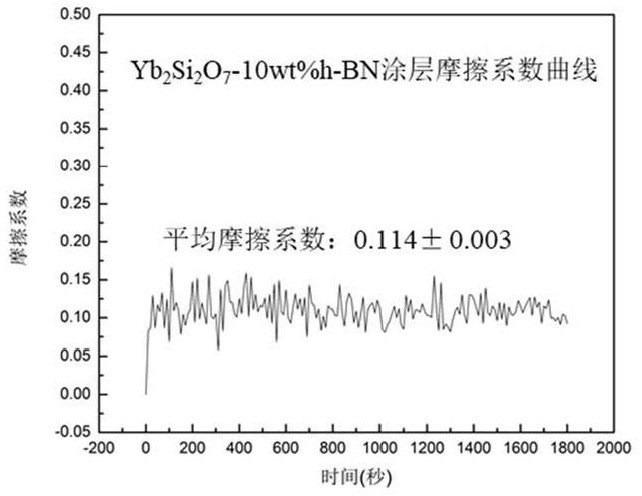

[0054] Using C / SiC as the substrate, the Si layer is prepared by plasma spraying method as the bonding layer, and the surface layer is Yb 2 Si 2 o 7 Coating, spraying process parameters are shown in Table 4. The prepared coating microhardness Hv 0.5 It is 4.44±0.23GPa. The abradability of the coating was evaluated by friction and wear experiments, and the evaluation conditions were the same as in Example 1. The average friction coefficient of the coating is 0.178±0.007, and the volume wear rate is (13.82±1.02)×10 -4 mm 3 / N·m. Compared with the YSZ coating in the comparative example, the microhardness is reduced by 25%, the friction coefficient is reduced by 12%, and the volume wear rate is increased by 135%. The performance requirements of lower coefficient of friction and higher wear rate of the layer.

[0055] Table 4 Plasma sprayed Yb 2 Si 2 o 7 Coating process parameters

[0056] Plasma gas Ar 38slpm Powder carrier gas Ar 2.5 slpm electric cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com