Preparation method of anti-slip bright-surface ceramic tile

A ceramic tile and surface glaze technology, applied in the field of building materials, can solve problems such as damage to the texture, color and pattern of tiles, easy adsorption of dirty substances, difficulty in cleaning, etc., and achieve the effects of improving friction coefficient, improving brightness, and excellent anti-skid performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

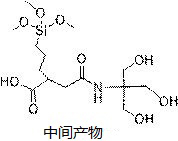

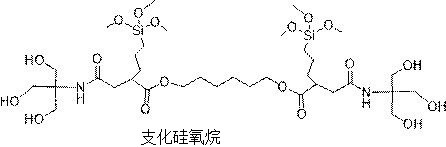

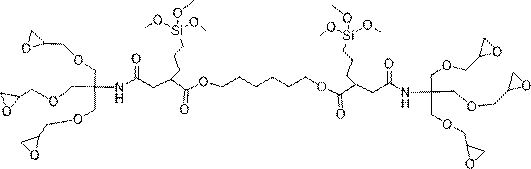

[0036] Preparation of branched epoxy siloxane:

[0037] Step A1. Add 0.01mol of trishydroxymethylaminomethane, 0.01mol of [3-(trimethoxysilyl)propyl]succinic anhydride and 100mL of absolute ethanol into a four-necked flask, stir well, and raise the temperature to reflux 8h, then lowered to room temperature, transferred the solution to a container, placed in an oven and dried under vacuum at 35°C to obtain an intermediate product; after mixing 0.02mol of the intermediate product and 0.01mol of 1,6-hexanediol uniformly, added the intermediate 5% p-toluenesulfonic acid by product mass, then heated to 80°C, stirred and reacted for 3 hours under nitrogen protection, to obtain branched siloxane;

[0038] Step A2: Add 0.01mol branched siloxane and 0.06mol epichlorohydrin into a three-necked flask equipped with a stirrer and a reflux device, heat up to 75°C under stirring conditions, and add in four batches after the temperature stabilizes 0.0308g catalyst NaH, after reacting for 4 h...

Embodiment 2

[0040] Preparation of branched epoxy siloxane:

[0041] Step A1. Add 0.01mol trishydroxymethylaminomethane, 0.014mol [3-(trimethoxysilyl)propyl]succinic anhydride and 150mL absolute ethanol into a four-neck flask, stir well, and raise the temperature to reflux 8h, then lowered to room temperature, transferred the solution to a container, placed in an oven and dried under vacuum at 35°C to obtain an intermediate product; after mixing 0.02mol of the intermediate product and 0.01mol of 1,6-hexanediol uniformly, added the intermediate 5% p-toluenesulfonic acid by product mass, then heated to 80°C, stirred and reacted for 3 hours under nitrogen protection, to obtain branched siloxane;

[0042] Step A2: Add 0.01mol branched siloxane and 0.065mol epichlorohydrin into a three-necked flask equipped with a stirrer and a reflux device, heat up to 75°C under stirring conditions, and add in four batches after the temperature stabilizes 0.0386g of catalyst NaH, after reacting for 4 hours, ...

Embodiment 3

[0044] The treatment fluid is made through the following steps:

[0045] Step A, after stirring 65g water, 0.5g emulsifier, 0.5g penetrant and 35g silica sol at room temperature and 300r / min, obtain silica sol emulsion, the emulsifier is sodium lauryl sulfate, the The penetrating agent is fatty alcohol polyoxyalkyl ether, the mass fraction of silicon dioxide in the silica sol is 20-30%, and the particle size of silicon dioxide is 80-150nm;

[0046] Step B: Add 7g of aminopropyltriethoxysilane to 100g of silica sol emulsion, mix well, adjust the pH value of the solution to 5.5, stir and react for 60min at 50°C, cool to room temperature, and then add 6.5g of Example 1. The prepared branched epoxy siloxane was stirred evenly at a speed of 700r / min to obtain a treatment solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com