Enamel glaze and preparation process thereof

An enamel glaze and process technology, applied in the field of ceramics, to achieve the effect of broadening the firing range, increasing the adhesion and increasing the firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

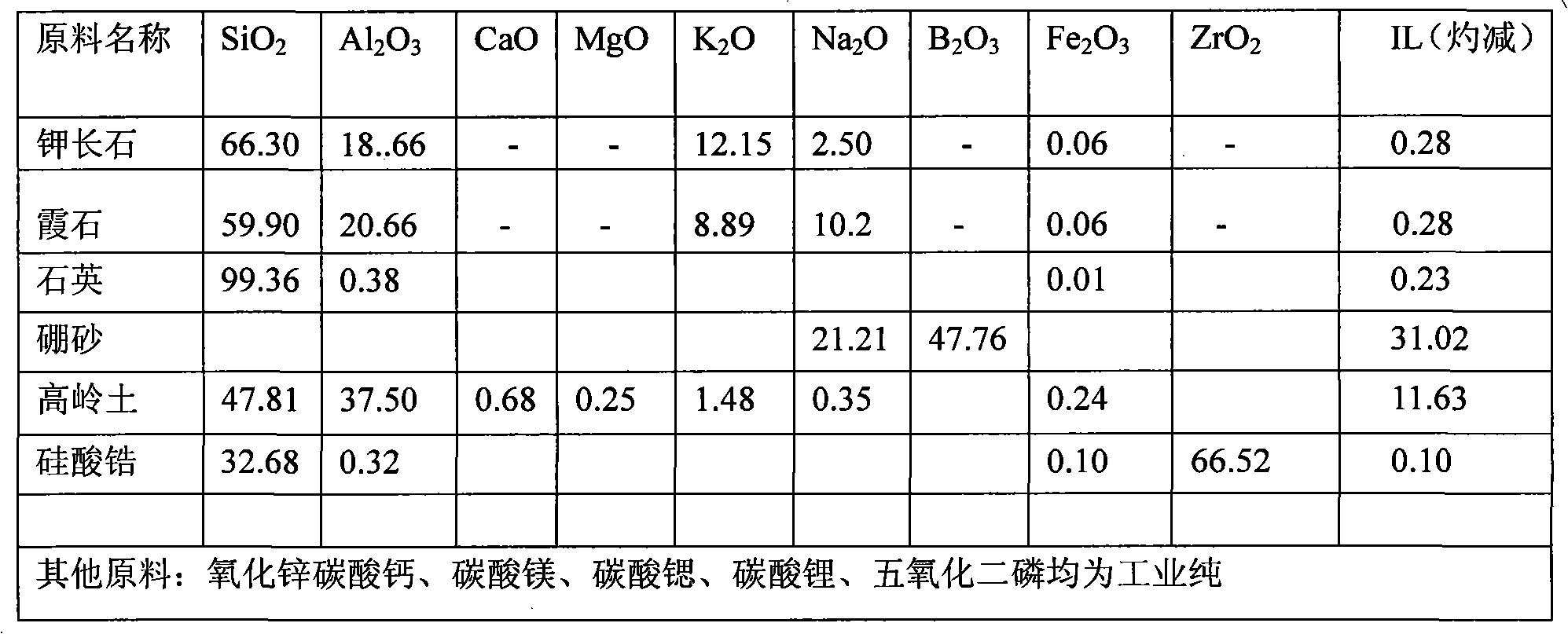

Method used

Image

Examples

Embodiment 1

[0032]Example 1: On the fine blank of the 480mm bone china vase, draw the outline of the dragon and the phoenix with a brush dipped in peelable glue, and then apply a layer of golden-yellow glaze on the outer surface of the fine blank of the 480 mm bone china vase. , The golden yellow color glaze is prepared according to the following formula: 25 parts of quartz powder (325 mesh), potassium feldspar powder (325 mesh): 25 parts, 10 parts of kaolin, 12 parts of borax, 5 parts of zinc oxide, 1 part of zirconium silicate, carbonic acid 11 parts of calcium, 5 parts of phosphorus pentoxide, 1 part of strontium carbonate, and 5 parts of lithium carbonate. After the above-mentioned raw materials are mixed uniformly, they are melted at 1400°C to 1450°C, and then quenched in cold water to form a frit. Put the frit into the ball mill, add water, high alumina ball stone and 6% kaolin to grind into glaze slurry, the fineness is controlled to be less than 0.03% of the 10,000-hole sieve, and...

Embodiment 2

[0035] Embodiment 2: on the 400mm hard porcelain flat disc fine blank, use a writing brush to dip the paraffin and draw the outline of the peony flower, and then on the outer surface of the 400mm hard porcelain flat disc fine blank, a layer of bright red color glaze, The bright red color glaze is prepared according to the following formula: 44 parts of quartz powder (325 mesh), nepheline powder (325 mesh): 20 parts, 6 parts of kaolin, 8 parts of borax, 6 parts of zinc oxide, 1 part of yttrium trioxide, calcium carbonate 9 parts, 2 parts of magnesium carbonate, 2 parts of strontium carbonate, 2 parts of lithium carbonate. After the above-mentioned raw materials are mixed uniformly, they are melted at 1450° C. and then quenched in cold water to form a frit. Put the frit into the ball mill, add water, high alumina balls and 10% kaolin to grind into glaze slurry, the fineness is controlled to be less than 0.03% of the 10,000-hole sieve, then dried at 80 ℃, and made into powder and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com