Zinc oxide resistance piece and preparation method thereof

A zinc oxide resistor sheet, resistor sheet technology, applied in resistor manufacturing, resistors, varistors, etc., can solve the problem of poor insulation ability of inorganic high-resistance layers, shorten the production cycle, save the pre-burning shrinkage process, Energy and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

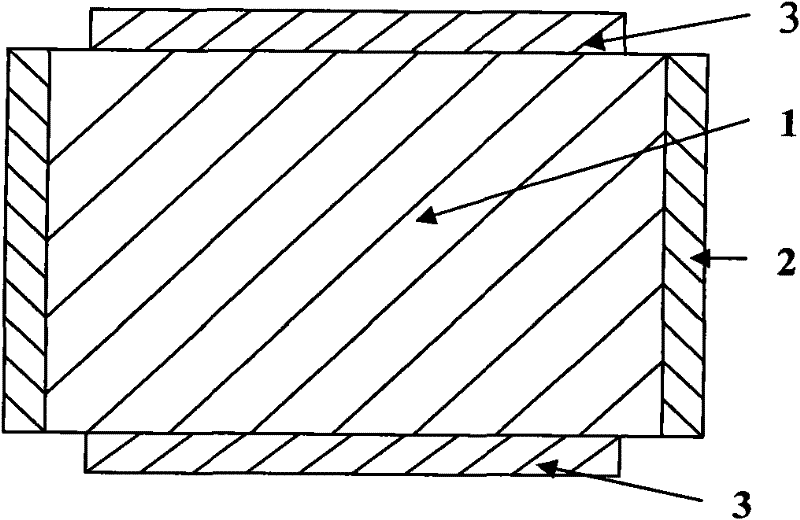

Image

Examples

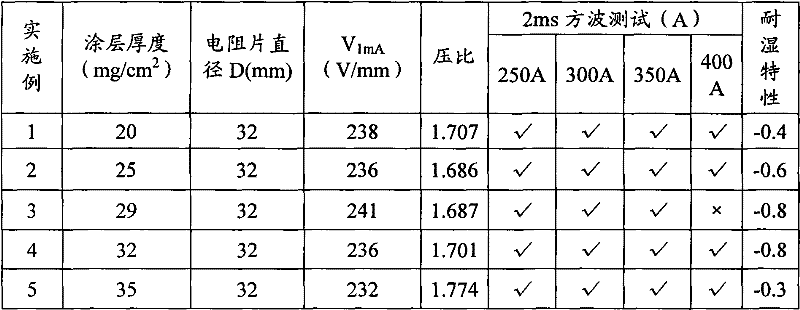

Embodiment 1~5

[0033] (1) Take 2.3g ZnO, 2g Bi 2 o 3 , 2.5g Sb 2 o 3 , 2.6g SiO 2 , 0.15g B 2 o 3 Mix evenly with 0.45g of mullite, add 20mL of PVA aqueous solution with a mass percent concentration of 2%, and use a planetary ball mill for 24 hours to obtain a slurry with a solid content of 30%.

[0034] (2) Use a coating machine to apply the slurry to the side of the zinc oxide resistor green body. When coating, the zinc oxide resistor green body is rotated for two weeks to ensure the uniformity of the coating. The coating thickness is controlled at 20-35mg / cm 2 . The coated sample was dried at 100°C, and then heated to 1200°C at a heating rate of 150°C / h for 2 hours, and then cooled to room temperature at a cooling rate of 100°C / h to obtain a sintered body, that is, a side with a high resistance layer of zinc oxide resistors.

[0035] The above-mentioned zinc oxide resistor with a high resistance layer on the side was tested for electrical performance and moisture resistance, and...

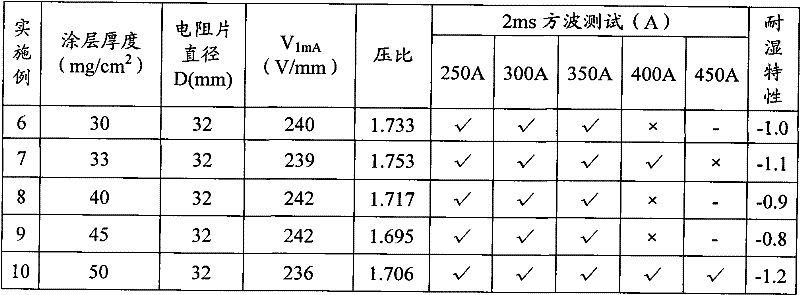

Embodiment 6~13

[0042] (1) Take 1.8g ZnO, 2.5g Bi 2 o 3 , 2.7g Sb 2 o 3 , 2.5g SiO 2 , 0.18g B 2 o 3 Mix evenly with 0.32g of mullite, add 15mL of PVA aqueous solution with a mass percent concentration of 2%, and use a planetary ball mill for 24 hours to obtain a slurry with a solid content of 40%.

[0043] (2) Apply the slurry to the side of the zinc oxide resistor green body by spraying, and the coating thickness is controlled at 30-50mg / cm 2 . The coated sample was dried at 100°C, then raised to 1200°C at a heating rate of 150°C / h and kept for 2 hours, and then lowered to room temperature at a cooling rate of 100°C / h to obtain a sintered body, that is, a side with a high resistance layer of zinc oxide resistors.

[0044] The above-mentioned zinc oxide resistor with a high resistance layer on the side was tested for electrical performance and moisture resistance, and the results are shown in Table 2 and Table 3.

[0045] Table 2

[0046]

[0047] table 3

[0048]

[0049] A...

Embodiment 14

[0051] (1) Take 0.8g ZnO, 3g Bi 2 o 3 , 2g Sb 2 o 3 , 3.5g SiO 2 , 0.5g B 2 o 3 Mix evenly with 0.2 g of mullite, add 90 mL of methyl cellulose aqueous solution with a mass percent concentration of 1%, and use a planetary ball mill for 10 hours to obtain a slurry with a solid content of 10%.

[0052] (2) Apply the slurry to the side of the zinc oxide resistor green body by dip coating, and the coating thickness is controlled at 7mg / cm 2 . The coated sample was dried at 100°C, then raised to 1100°C at a heating rate of 150°C / h and kept for 2 hours, and then lowered to room temperature at a cooling rate of 100°C / h to obtain a sintered body, that is, a side with a high resistance layer of zinc oxide resistors.

[0053] The above-mentioned zinc oxide resistors with high-resistance layers on the side were tested for electrical performance and moisture resistance, and found that their performance was equivalent to that of the resistors in Examples 1-13, and was significantly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com