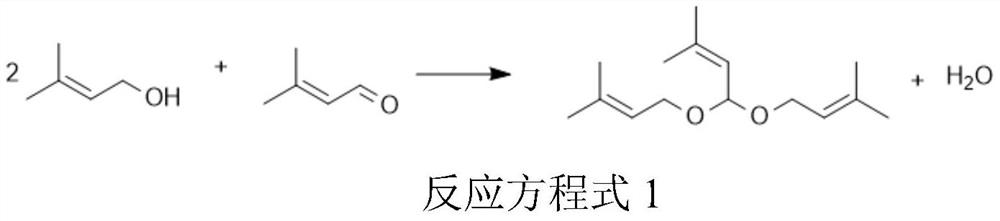

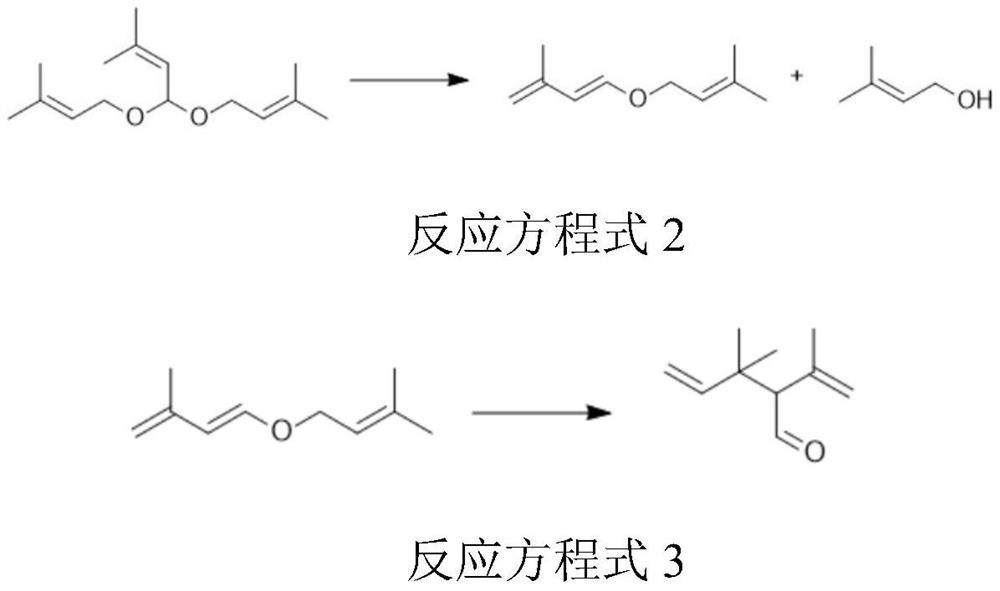

Preparation method of 3-methyl-2-butene-1-aldehyde diisopentenyl acetal

A technology of aldehyde di-prenyl acetal and prenyl alcohol, which is applied in the field of preparation of 3-methyl-2-butene-1-aldehyde di-prenyl acetal, can solve the problem of citral Problems such as the influence of the selectivity and yield of the condensation reaction of intermediates, to achieve the effect of improving selectivity, reducing side reactions, and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041]300 g of prenyl alcohol content of 63 wt%, prenyl aldehyde content of 35 wt%, 2,4,4-trimethyl-3-formyl-1,5-hexadiene content of 2 wt% isopentene After the content of alcohol B and 1050g 2,4,4-trimethyl-3-formyl-1,5-hexadiene is 4wt% isopentenol C mixed (the mass ratio of two flows of B and C is 0.3:1.05), into the water azeotropic rectification column for purification. The water consumption is 675g, which is 50wt% of the total mass of the mixture of prenyl alcohols B and C, operated at normal pressure, and the number of packing plates in the azeotropic separation tower is 20, and the mixture of prenyl alcohols B and C is in the rectification tower The upper part of the feed, the feed rate is 2.5g / min, water is fed in the lower part of the rectification tower, the feed rate is 1.25g / min, the temperature at the top of the tower is 94°C, and the temperature at the bottom of the tower is 101°C ; After the steam at the top of the rectification tower is condensed, the phase s...

Embodiment 2

[0046] 9000g of isoamyl alcohol with 89.5wt% prenol, 10wt% prenal and 0.5wt% 2,4,4-trimethyl-3-formyl-1,5-hexadiene After the content of pentenol B and 990g 2,4,4-trimethyl-3-formyl-1,5-hexadiene is 1wt% prenol C after mixing (the mass of B, C two flows Ratio is 9:0.99), enters the water azeotropic rectification tower to carry out purification. The water consumption is 999g, which is 10wt% of the total mass of the mixture of prenyl alcohols B and C, operated at normal pressure, and the number of packing plates in the azeotropic separation tower is 25, and the mixture of prenyl alcohols B and C is in the rectification tower The upper part of the feed is fed at a feed rate of 2.5g / min, water is fed at the lower half of the rectification tower, the feed rate is 0.25g / min, the temperature at the top of the tower is 96°C, and the temperature at the bottom of the tower is 103°C ; After the steam at the top of the rectification tower is condensed, the phase separation is carried out...

Embodiment 3

[0051] 4500g of prenol content of 76.25wt%, prenyl aldehyde content of 22.50wt%, 2,4,4-trimethyl-3-formyl-1,5-hexadiene content of 1.25wt% The content of isopentenol B and 1020g 2,4,4-trimethyl-3-formyl-1,5-hexadiene is 2.5wt% after mixing prenol C (B, C two flows The mass ratio is 4.5:1.02), enters the water azeotropic rectification column and purifies. The water consumption is 1656g, which is 30wt% of the total mass of the prenol mixture B and C after mixing, operated under normal pressure, and the packing plate number of the azeotropic separation tower is 15, and the mixture of prenol B and C in the rectification tower The upper part of the feed, the feed rate is 2.5g / min, water is fed in the lower part of the rectification tower, the feed rate is 0.75g / min, the temperature at the top of the tower is 95 ° C, and the temperature of the bottom of the tower is 102 ° C ; After the steam at the top of the rectification tower is condensed, the phase separation is carried out in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com