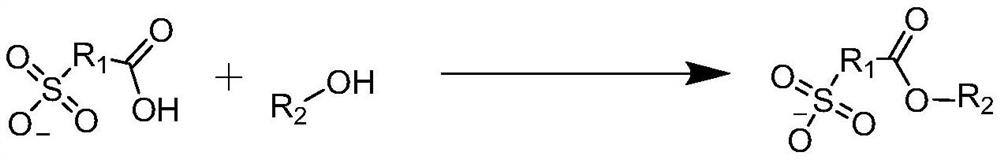

Preparation method of sulfonate alkane ester

A technology of sulfonate alkane ester and sulfonate alkane carboxylic acid, which is applied in the chemical field, can solve the problems of long reaction time and unsatisfactory synthesis effect, and achieve the effects of fast reaction speed, good photolithographic pattern quality, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

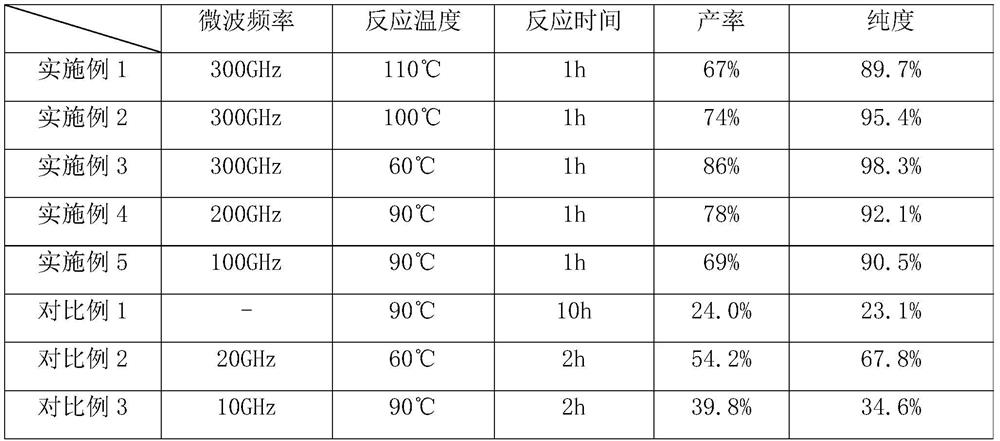

Embodiment 1

[0033] Embodiment 1 A kind of preparation method of sulfonate alkane ester

[0034] Include the following steps:

[0035] (1) Sodium sulfonate acetic acid and methanol were placed in a four-neck flask filled with toluene, and stirred until dissolved to obtain a reaction solution. The mass ratio of the sodium sulfonate acetic acid, methanol and toluene consumption is: 81:12:200.

[0036] (2) Place the four-necked flask in a microwave reactor, and slowly feed nitrogen into the four-necked flask for 30 minutes to get rid of the oxygen in the bottle;

[0037] (3) After raising the temperature of the reaction solution in the four-neck flask to 110°C, turn on the microwave, and control the microwave frequency to 300GHz to carry out the esterification reaction; control the microwave time to 1h, and turn off the microwave reactor after 1h to end the reaction;

[0038] (4) Take out the four-neck flask in the microwave reactor to remove impurities. The impurity removal: the reaction ...

Embodiment 2

[0041] Embodiment 2 A kind of preparation method of sulfonate alkane ester

[0042] Include the following steps:

[0043] (1) Sodium sulfonate acetic acid and methanol were placed in a four-neck flask filled with toluene, and stirred until dissolved to obtain a reaction solution. The mass ratio of the sodium sulfonate acetic acid, methanol and toluene consumption is: 81:12:200.

[0044] (2) Place the four-necked flask in a microwave reactor, and slowly feed nitrogen into the four-necked flask for 30 minutes to get rid of the oxygen in the bottle;

[0045] (3) After raising the temperature of the reaction solution in the four-neck flask to 100°C, turn on the microwave, and when the microwave frequency is set to 300GHz, carry out the esterification reaction; control the microwave time to 1h, and turn off the microwave reactor after 1h to end the reaction;

[0046] (4) Take out the four-neck flask in the microwave reactor to remove impurities. The impurity removal: pour the re...

Embodiment 3

[0049] Embodiment 3 A kind of preparation method of sulfonate alkane ester

[0050] Include the following steps:

[0051] (1) Place sodium sulfonate acetic acid and methanol in a four-necked flask filled with toluene, and stir until dissolved; a reaction solution is obtained. The mass ratio of the sodium sulfonate acetic acid, methanol and toluene consumption is: 81:12:200.

[0052] (2) Place the four-necked flask in a microwave reactor, and slowly feed nitrogen into the four-necked flask for 30 minutes to get rid of the oxygen in the bottle;

[0053] (3) After the temperature of the reaction solution in the four-neck flask was raised to 60°C, when the microwave frequency was set to 300GHz, the microwave was turned on to carry out the esterification reaction; the microwave time was controlled to be 1h, and the microwave reactor was turned off after 1h to end the reaction;

[0054](4) Take out the four-neck flask in the microwave reactor to remove impurities. The impurity re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com