Corrosion-resistant strong-adhesion FEVE water-based fluorocarbon color paste and preparation method thereof

A water-based fluorocarbon and water-based fluorocarbon emulsion technology, applied in the direction of pigment paste, etc., can solve the problems of reduced adhesion of FEVE water-based fluorocarbon paste and reduced corrosion resistance of coatings, so as to improve adhesion performance and improve dispersion effect. , the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

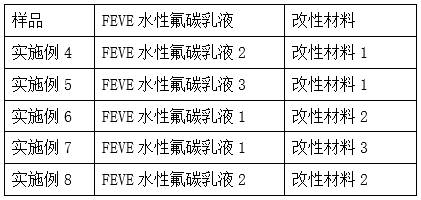

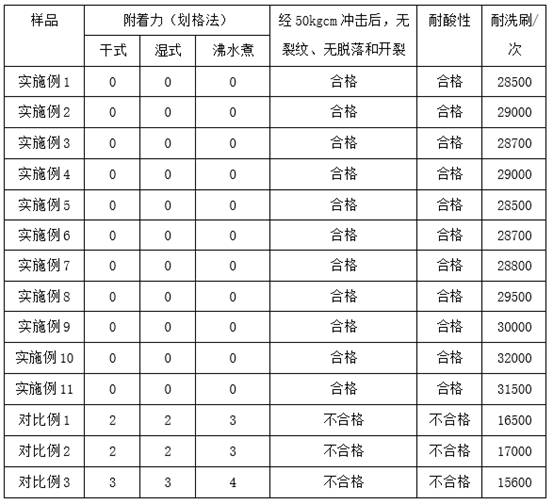

Examples

preparation example 1

[0046] A modified material 1:

[0047] 8 kg of trimethylolpropane three (3-mercaptopropyl ester) and 6 kg of 3-aminopropyltriethoxysilane were mixed with 6 kg of tetrahydrofuran, and the reaction was heated at 50 ° C for 12 h, and the reaction liquid was collected and the solvent was removed. Collect reactants;

[0048] Nano-hydroxyapatite with 0.5 kg of 2 to 10 μm was stirred with 2 kg of reactants and were placed in 200 W under ultrasonic dispersion. After the dispersion treatment, the reaction was heated at 50 ° C for 12 h, and the dried and dried can be prepared. .

preparation example 2

[0050] Modified material 2:

[0051] 8 kg of trimethylolpropane three (3-mercaptopropyl ester) and 6 kg of 3-aminopropyltriethoxysilane were mixed with 6 kg of tetrahydrofuran, and the reaction was heated at 50 ° C for 12 h, and the reaction liquid was collected and the solvent was removed. Collect reactants;

[0052] Nano-hydroxyapatite with 0.5 kg of 11 to 80 μm was mixed with 2 kg of reactants and was stirred in 200 W. After the dispersion treatment, the reaction was heated at 50 ° C for 12 h, and the dried and dried can prepare the modified material 2. .

preparation example 3

[0054] Modified material 3:

[0055] 8 kg of trimethylolpropane three (3-mercaptopropyl ester) and 6 kg of 3-aminopropyltriethoxysilane were mixed with 6 kg of tetrahydrofuran, and the reaction was heated at 50 ° C for 12 h, and the reaction liquid was collected and the solvent was removed. Collect reactants;

[0056] Nano-hydroxyapatite with 0.5 kg of 81 to 100 μm was stirred with 2 kg of reactants and were placed at 200 W under ultrasonic dispersion. After dispersion treatment, the reaction was heated at 50 ° C for 12 h, and the modified material 3 was prepared. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com