Method for performing cyclic enzymolysis saccharification on lignocellulose by using multi-enzyme synergistic surfactant

A technology of surfactant and circulating enzyme, applied in fermentation and other directions, can solve the problems of high cost of enzyme, high cost and high amount of enzyme, and achieve the effect of simple operation, reducing the cost of enzymolysis and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the pretreatment of wood

[0027] (1) Clean poplar wood and use a pulverizer to pulverize it. After passing through an 80-mesh sieve, put the sawdust in an oven at 60° C. and bake to constant weight;

[0028] (2) Take 50g of sawdust, use 4% sodium hydroxide to mix well according to the ratio of material to liquid 1:10 (g:mL), and place it at 121°C for 90min;

[0029] (3) Wash the poplar sawdust with pure water until it is neutral, then put it in an oven at 60°C, bake it to constant weight, and set it aside.

Embodiment 2

[0030] Embodiment 2: the secondary pretreatment of hydrogen peroxide and laccase

[0031] (1) The sawdust treated in Example 1 was fully mixed with acetic acid sodium acetate buffer according to the ratio of solid to liquid at 1:10 (g:mL);

[0032] (2) Add 50 mL of 10% hydrogen peroxide and 50 U / g sawdust laccase, and pretreat at 50°C for 12 hours;

[0033] (3) Use a vacuum pump to filter the wood chips that have been pretreated twice to obtain filtrate and filter residue, wherein the filtrate is recovered and stored in cold storage for easy reuse, and the filter residue is ready for use.

Embodiment 3

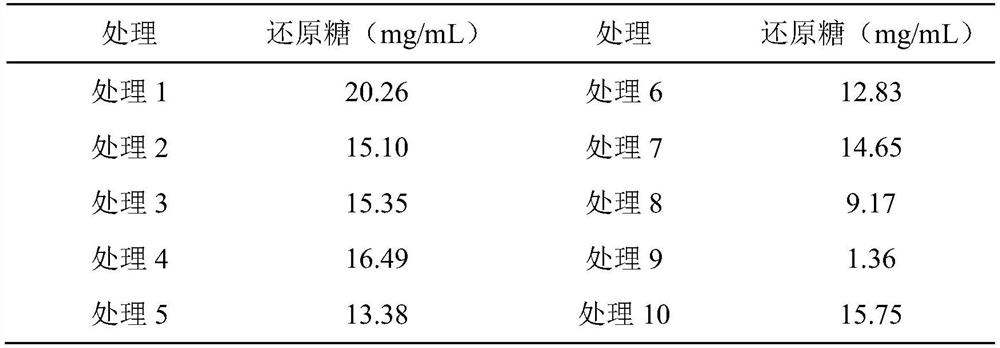

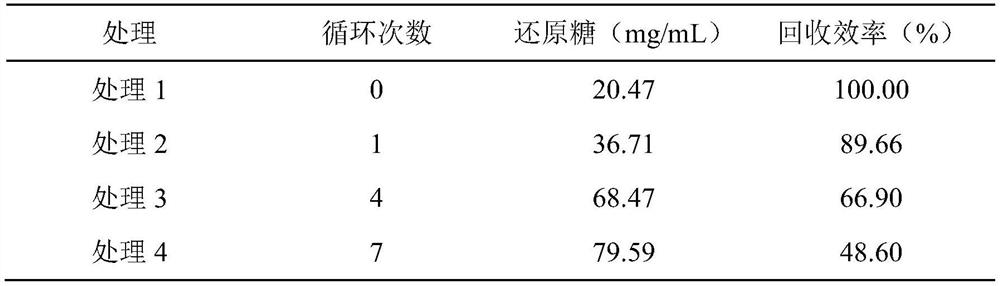

[0034] Embodiment 3: the pre-enzymolysis of xylanase and surfactant

[0035] (1) the poplar filter residue obtained in Example 2 is thoroughly mixed with acetic acid sodium acetate buffer solution according to the ratio of solid to liquid 1:10 (g:mL);

[0036] (2) Add 60 U / g wood chips xylanase and 0.05 g / g wood chips non-ionic surfactant Tween-80 for pre-enzymolysis for 2 hours;

[0037] (3) Use a vacuum pump to filter the pre-enzymolyzed sawdust to obtain filtrate and filter residue, wherein the filtrate is recovered and stored in cold storage for easy reuse, and the filter residue is used for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com