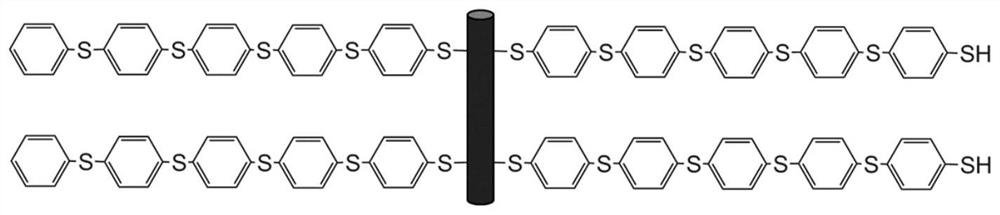

Polyphenylene sulfide linear oligomer grafted modified carbon fiber as well as preparation method and application thereof

A polyphenylene sulfide and graft modification technology, which is applied in the fields of carbon fiber, fiber processing, textile and paper making, etc., can solve the problems of production waste and difficult to use effectively, improve compatibility, and realize high-value reuse. , the effect of improving the comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] At 100 °C, 100 g of commercial CF was refluxed with acetone for 48 h to remove the surface sizing agent. The desizing CF was oxidized with 3000 mL of 65wt% concentrated nitric acid for 4 h, and active groups such as -OH and -COOH were introduced on the surface of CF, washed and dried in vacuum to obtain surface oxidized carbon fibers (CFO).

[0036] The CFO fiber tow is put into the round-bottomed flask, and 5000 g of MPTES (methacryloyloxypropyl tris(trimethylsiloxane) silane) solution (concentration is 0.05 g / mL) is added to the above-mentioned solution. The reaction device was adjusted to pH 5-6 with glacial acetic acid, left to stand at 30° C. for 1 hour, washed and dried in vacuum to obtain carbon fiber (CFO-MPTES) grafted on the surface of MTPES.

[0037] Using acetone (also tetrahydrofuran, chloroform, acetonitrile, dimethylformamide, etc.) as a solvent to prepare a LPS solution with a concentration of 0.01g / mL, CFO-MPTES, 2g catalyst 2,2-dimethoxy-2- Phenylacet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com