Method for testing button type half cell made of lithium ion battery electrode material

A lithium-ion battery and electrode material technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc. Storage capacity, optimized battery assembly process, environmentally safe and friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

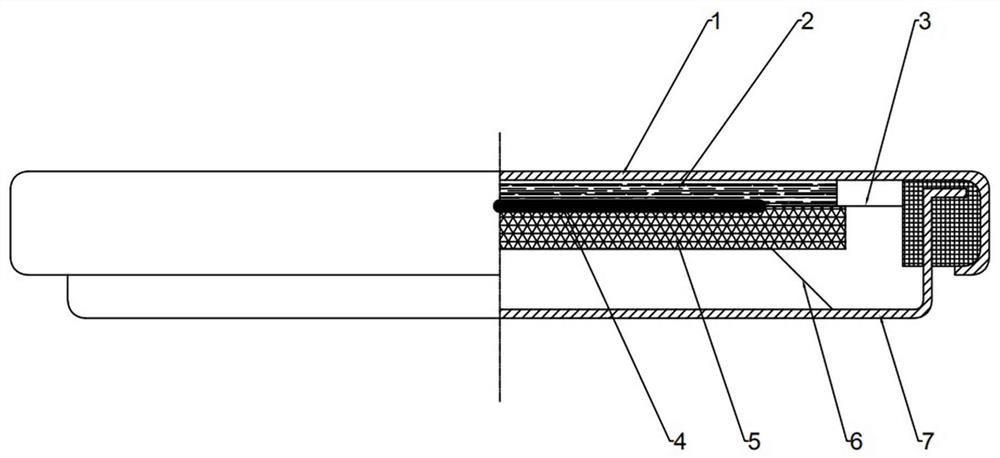

Image

Examples

Embodiment 1

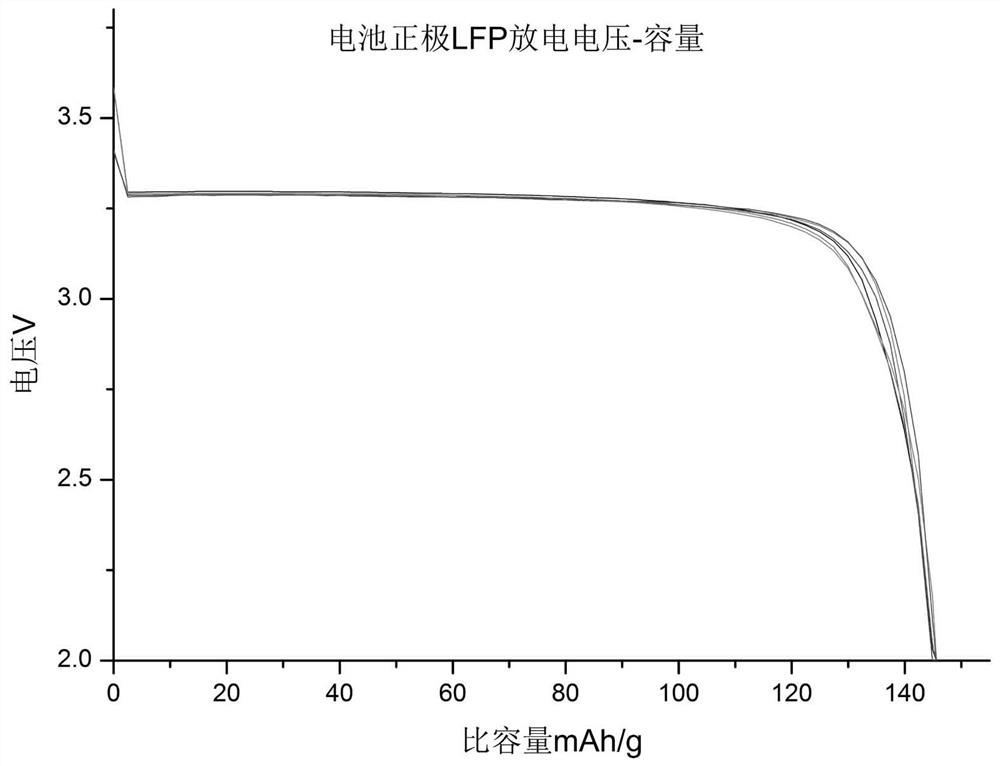

[0065] Embodiment 1, lithium iron phosphate as active material:

[0066] 1) Vacuum bake the lithium iron phosphate material to be tested in an oven at 120°C for 4 hours; bake Super P and KS-15 in an oven at 120°C for 12 hours, and bake PVDF in an oven at 80°C for 12 hours. :KS-15:PVDF:NMP=2.75:1.1:3:112.75 ratio to prepare a slurry, after vacuum stirring for 4 hours to obtain a uniform slurry A.

[0067] 2) According to the ratio of lithium iron phosphate: slurry A=9.315:11.9600, weigh the lithium iron phosphate material and the slurry into a ball mill jar, and add agate ball milling beads φ6:15 and φ10:8. After putting the ball mill jar into the ball mill, run it at 200r / min for 5min, then adjust the speed to 500r / min for 1h.

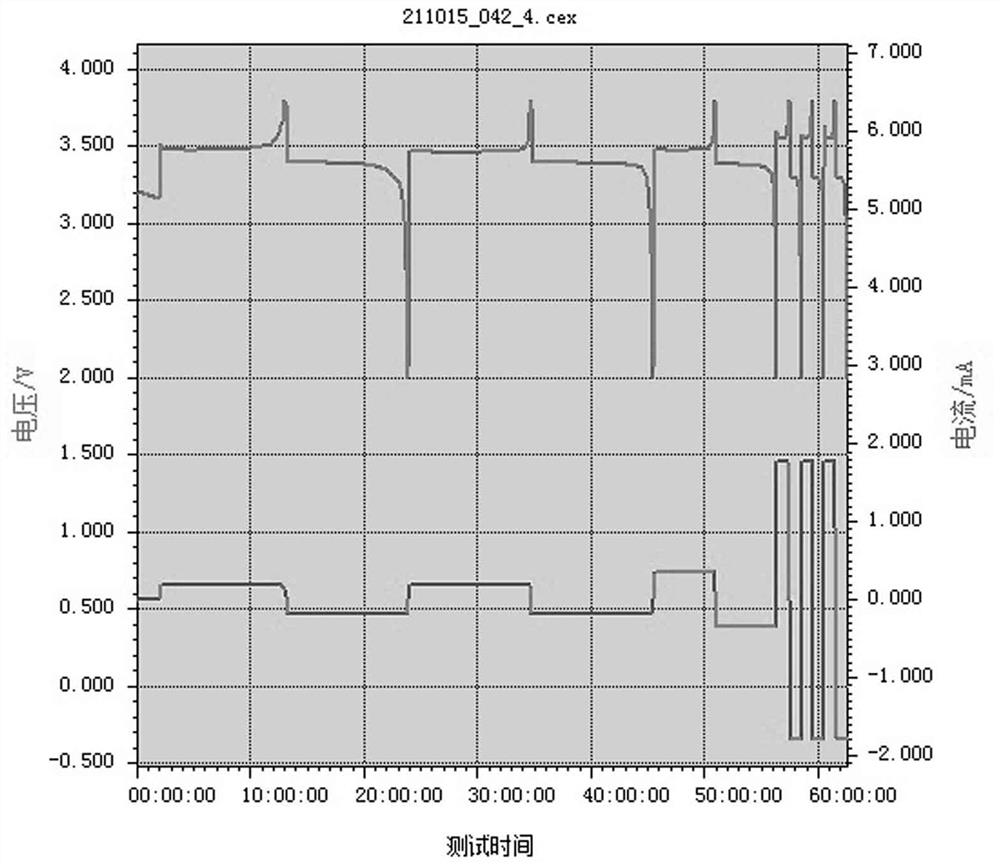

[0068] 3) After the ball milling, pour the obtained slurry on the clean and dry aluminum foil, adjust the scraper to 180-200μm, scrape the slurry evenly on the aluminum foil, dry the NMP at 120°C, and put it in a vacuum oven at 120°C Dry for 3h. The...

Embodiment 2

[0082] Embodiment 2: Ternary material is used as active material:

[0083] 1) According to the ratio of ternary material: slurry A (obtained in Example 1) = 9.315:11.9600, weigh the ternary material and slurry into a ball mill jar, and add agate ball milling beads φ6:15 and φ10:8. After putting the ball mill jar into the ball mill, run it at 200r / min for 5min, then adjust the speed to 500r / min for 1h.

[0084] 2) After ball milling, pour the resulting slurry on a clean and dry aluminum foil, adjust the scraper to 180-200 μm, scrape the slurry evenly on the aluminum foil, dry the NMP at 120°C, and put it in a vacuum oven at 120°C Dry for 3h. The surface capacity of the obtained electrode should be controlled at 1-3mAh / cm².

[0085] 3) Take the pole piece obtained above out of the oven and cut off the blank aluminum foil, clean the surface until it is dust-free, adjust the rollers for 50μm, 40μm, and 30μm rolling once respectively, and control the compaction density of the pol...

Embodiment 3

[0098] Example 3, the active site is graphite negative electrode material.

[0099]1) Bake the graphite anode material to be tested in an oven at 80°C for 1 hour; bake Super P in an oven at 120°C for 12 hours, and bake PVDF in an oven at 80°C for 12 hours. The ratio of 1:5:138 was weighed, the slurry was prepared, and the slurry was stirred for 4 hours to obtain the slurry B.

[0100] 2) Weigh an appropriate amount of graphite material: slurry B into a 100ml ball mill jar according to the ratio of 9.4:14.4, and add agate ball mill beads φ6:15 and φ10:8. After putting the ball mill jar into the ball mill, run it at 200r / min for 5min, then adjust the speed to 500r / min for 1h.

[0101] 3) After the ball milling, pour the obtained slurry on the clean and dry copper foil, adjust the scraper to 200μm, scrape the slurry evenly on the copper foil, dry the NMP at 120°C, and put it in a vacuum oven at 100°C Dry for 3h.

[0102] 4) Take the pole piece obtained above out of the oven an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com