Negative electrode material and preparation method and application thereof

A negative electrode material and silicon-based material technology, applied in the field of negative electrode materials and their preparation, can solve problems such as limited electron transport capacity of conductive polymers, and inability to meet high-rate charge and discharge of lithium-ion batteries, so as to improve cycle performance and improve Conductivity, the effect of reducing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

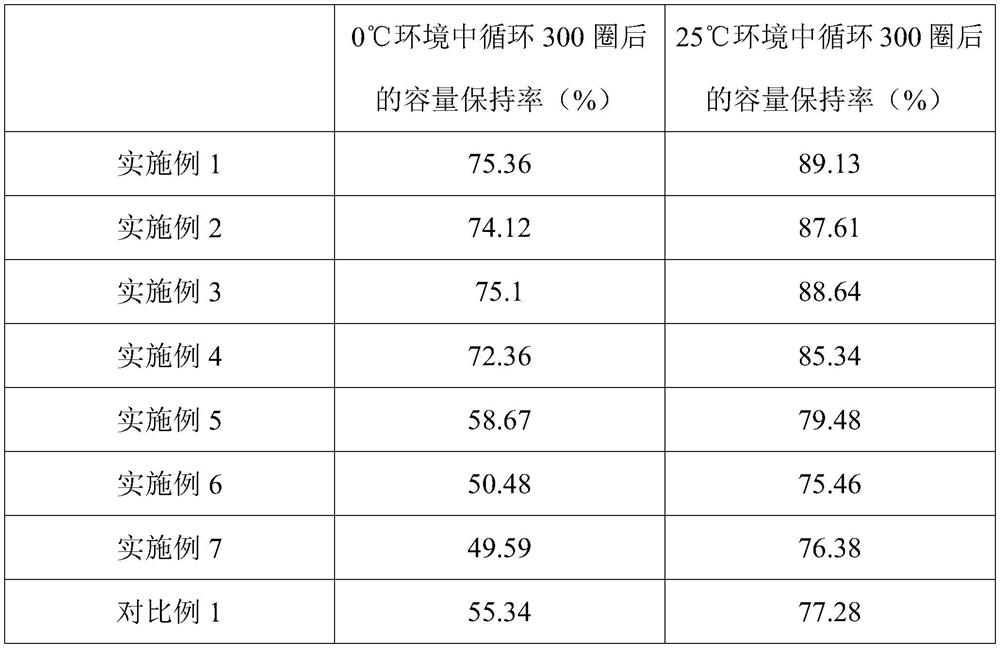

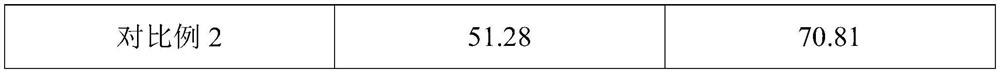

Examples

Embodiment 1

[0046] This embodiment provides a preparation method of negative electrode material, the method is as follows:

[0047] (1) Nano-silicon (median particle size is 200nm) and peach gum are ball milled for 12h with a mass ratio of 1:10 to obtain a mixture;

[0048] (2) The mixture described in step (1) and the metaphosphoric acid solution (concentration is 2.5%) are mixed and stirred at 40° C. for 3 h at a mass ratio of 1:8, and then mixed in a mixed atmosphere of nitrogen and hydrogen (nitrogen and hydrogen) The volume ratio is 98:2) at a heating rate of 5 °C / min to 600 °C and then sintered for 4 hours to obtain a negative electrode material with a nano-silicon surface coated with a porous carbon layer.

Embodiment 2

[0050] This embodiment provides a preparation method of negative electrode material, the method is as follows:

[0051] (1) Ball milling silicon dioxide and peach gum for 18 hours at a mass ratio of 1:15 to obtain a mixture;

[0052] (2) The mixture described in step (1) and the metaphosphoric acid solution (concentration is 2.5%) are mixed and stirred at 40° C. for 3 hours at a mass ratio of 1:5, and then mixed in a mixed atmosphere of nitrogen and hydrogen (nitrogen and hydrogen) The volume ratio is 98:2) at a heating rate of 2 °C / min to 350 °C and then sintered for 8 hours to obtain a negative electrode material with a silicon oxide surface coated with a porous carbon layer.

Embodiment 3

[0054] This embodiment provides a preparation method of negative electrode material, the method is as follows:

[0055] (1) Carry out ball milling 10h with silicon dioxide and peach gum with the mass ratio of 1:5, obtain mixture;

[0056] (2) The mixture described in step (1) and the metaphosphoric acid solution (concentration is 2.5,) are mixed and stirred at 40° C. for 3 hours at a mass ratio of 1:8, and then mixed in a mixed atmosphere of nitrogen and hydrogen (nitrogen and hydrogen) The volume ratio is 98:2) at a heating rate of 10 °C / min to 800 °C and then sintered for 4 hours to obtain a negative electrode material with a porous carbon layer coated on the surface of silicon dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com