Simple synthesis method capable of controlling three-dimensional structure of nanometer cobaltosic oxide

A technology of cobalt tetroxide and three-dimensional structure, applied in cobalt oxide/cobalt hydroxide, nanotechnology and other directions, can solve the problems of complex process, high cost, easy to pollute the environment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Using cobalt nitrate hexahydrate as the cobalt source, threonine as the ligand, and deionized water as the solvent, the ligand and Co 2+ A solution with a substance ratio of 2.0, ultrasonically stirred for 20 minutes at room temperature to form a dark red transparent solution;

[0037] 2) Prepare a 1mol / L NaOH aqueous solution, add it and concentrated nitric acid with a concentration of 36% (wt) dropwise to the solution prepared in step 1), and stir fully to obtain a solution with a pH value of 9.3;

[0038] 3) Transfer the mixed system obtained in step 2) to a self-pressurized hydrothermal reaction kettle, seal it, and place it in a high-temperature oven at 120° C. for 12 hours;

[0039] 4) After the reaction, the product was collected by centrifugation, washed three times with deionized water and absolute ethanol, and then dried in air at 80°C for 6 hours;

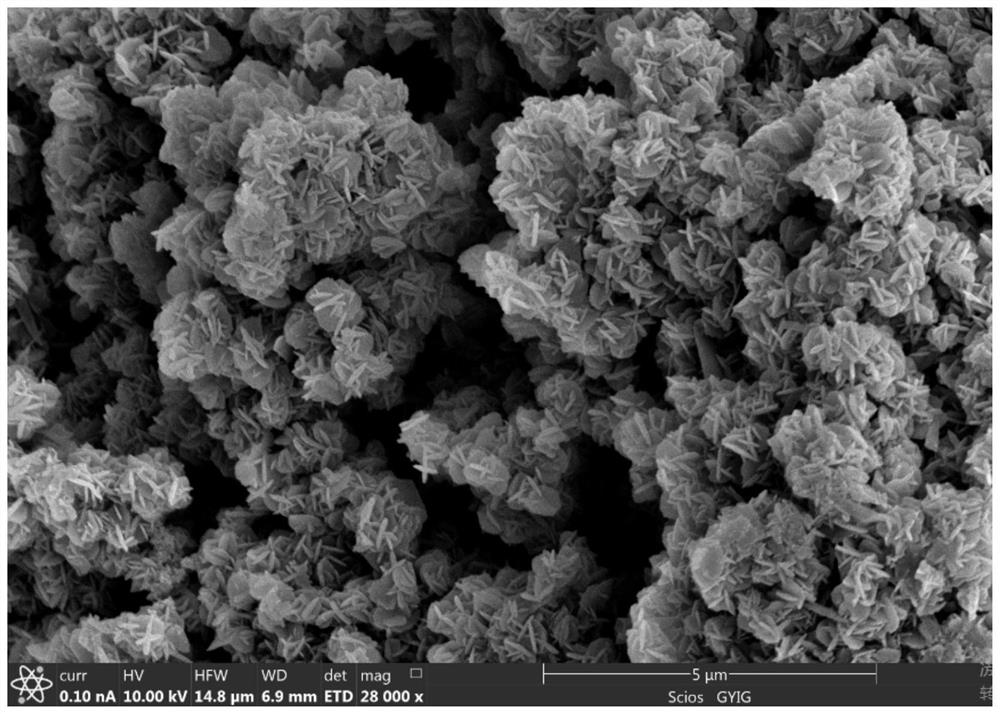

[0040] 5) The dried samples were taken for phase and morphology characterization. Scanning electron micros...

Embodiment 2

[0043] 1) Using cobalt nitrate hexahydrate as the cobalt source, threonine as the ligand, and deionized water as the solvent, the ligand and Co 2+ A solution with a substance ratio of 2.0, ultrasonically stirred for 20 minutes at room temperature to form a dark red transparent solution;

[0044] 2) Prepare a 1mol / L NaOH aqueous solution, add it and concentrated nitric acid with a concentration of 36% (wt) dropwise to the solution prepared in step 1), and stir fully to obtain a solution with a pH value of 6.0;

[0045] 3) Transfer the mixed system obtained in step 2) to a self-pressurized hydrothermal reaction kettle, seal it, and place it in a high-temperature oven at 120° C. for 12 hours;

[0046] 4) After the reaction, the product was collected by centrifugation, washed three times with deionized water and absolute ethanol, and then dried in air at 80°C for 6 hours;

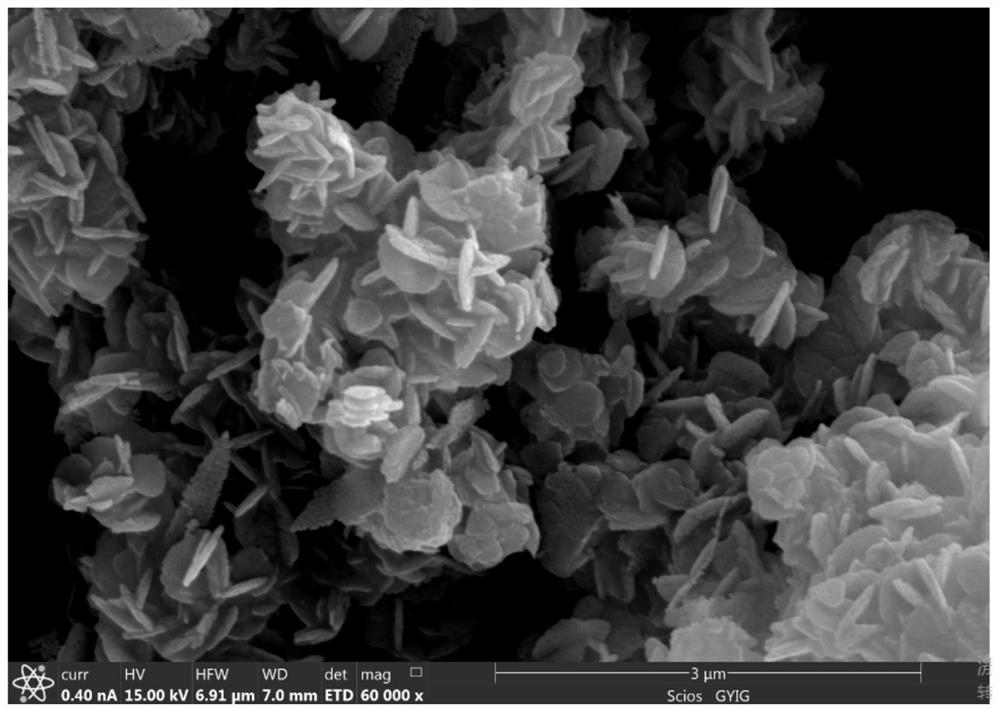

[0047] 5) The dried samples were taken for phase and morphology characterization. Scanning electron micros...

Embodiment 3

[0049] 1) Using cobalt nitrate hexahydrate as the cobalt source, threonine as the ligand, and deionized water as the solvent, the ligand and Co 2+ A solution with a substance ratio of 2.0, ultrasonically stirred for 20 minutes at room temperature to form a dark red transparent solution;

[0050] 2) Prepare a 1mol / L NaOH aqueous solution, add it and concentrated nitric acid with a concentration of 36% (wt) dropwise to the solution prepared in step 1), and stir fully to obtain a solution with a pH value of 7.3;

[0051] 3) Transfer the mixed system obtained in step 2) to a self-pressurized hydrothermal reaction kettle, seal it, and place it in a high-temperature oven at 120° C. for 12 hours;

[0052] 4) After the reaction, the product was collected by centrifugation, washed three times with deionized water and absolute ethanol, and then dried in air at 80°C for 6 hours;

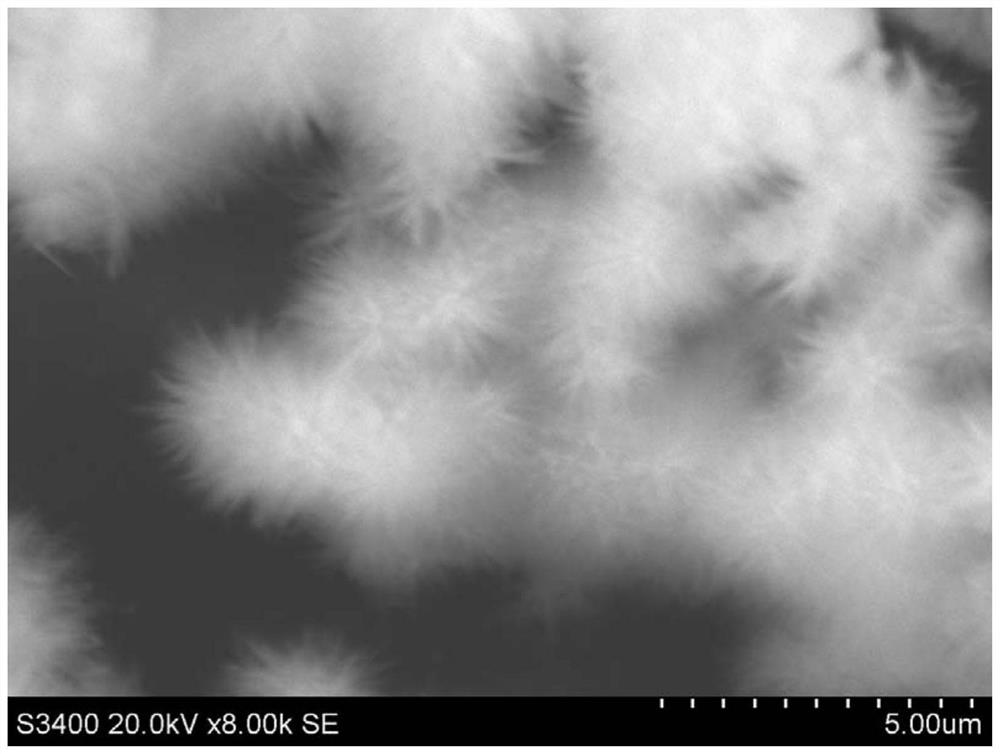

[0053] 5) The dried samples were taken for phase and morphology characterization. Scanning electron micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com