High-temperature-resistant high-reflectivity coating component and preparation method thereof, and coating and construction method thereof

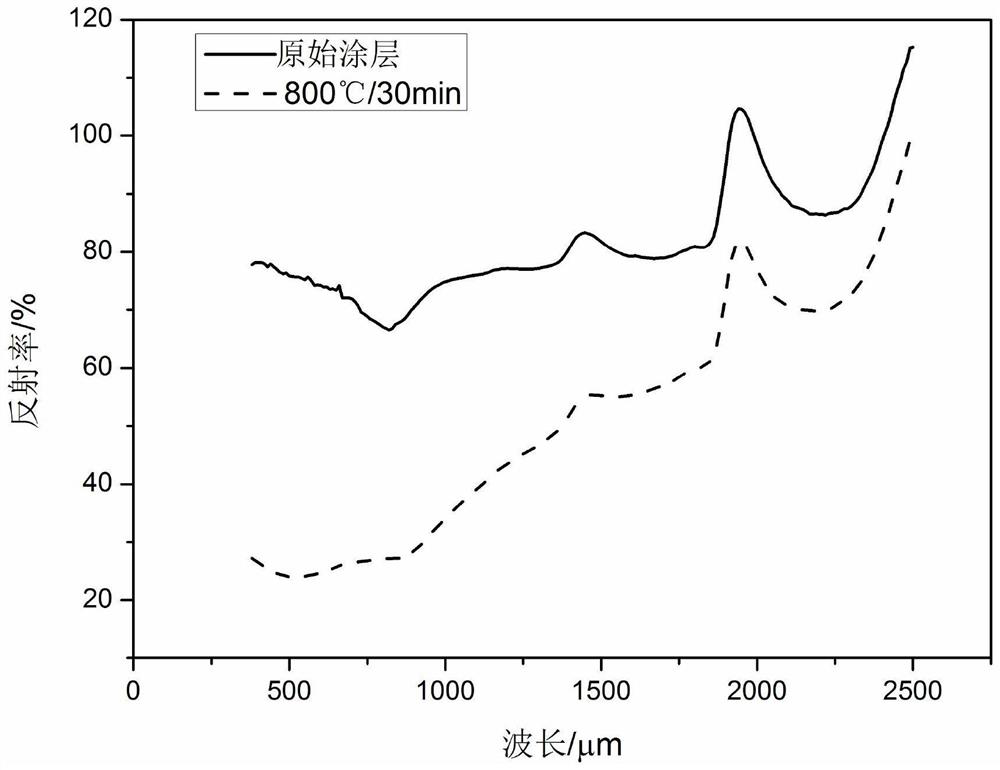

A high-reflectivity, paint-component technology, used in reflective/signal paints, coatings, buildings, etc., to solve problems such as blistering, inability to reflect infrared light, and reduced reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The high-temperature-resistant high-reflectivity coating consists of components A and B, in parts by weight, wherein 1) the formula of component A is: epoxy-modified polysiloxane resin (viscosity 120cp, epoxy equivalent 130, 20 parts) , phenyl polysiloxane resin (30% phenyl content, 80 parts), high reflectivity coating powder (35 parts), ultra-fine AZO (particle size 20nm, 5 parts), nano fumed silica (particle size 7nm, 15 parts), barite powder (particle size 10μm, 10 parts), ultrafine flaky brass powder (particle size 10μm, 15 parts), raybo 41 (2 parts), xylene 10 parts, butyl acetate 10 2) Component B is polysilazane (5 parts) with a number average molecular weight of 1000.

[0082] The preparation process of the above-mentioned high-reflectivity coating powder is as follows: 1) Pour 200g of mica powder (1200 mesh) into 2000g of 0.08mol / L nitric acid aqueous solution for ultrasonic activation for 0.5h, add sodium carbonate to adjust the pH of the solution to 6.5, and ...

Embodiment 2

[0090] The high-temperature-resistant high-reflectivity coating is composed of components A and B, in parts by weight, wherein 1) the formula of component A is: epoxy-modified polysiloxane resin (viscosity 120cp, epoxy equivalent 150, 20 parts) , phenyl polysiloxane resin (30% phenyl content, 80 parts), high reflectivity coating powder (35 parts), ultra-fine AZO (particle size 30nm, 8 parts), nano fumed silica (particle size 14nm, 20 parts), barite powder (particle size 10μm, 15 parts), ultrafine flaky brass powder (particle size 5μm, 15 parts), raybo 41 (3 parts), xylene 10 parts, butyl acetate 12 2) Component B is polysilazane (10 parts) with a molecular weight of 5000.

[0091] The preparation process of the above-mentioned high-reflectivity coating powder is as follows: 1) Pour 200g of mica powder (1200 mesh) into 2000g of 0.08mol / L nitric acid aqueous solution for ultrasonic activation for 0.5h, add sodium carbonate to adjust the pH of the solution to 6.5, and filter for ...

Embodiment 3

[0098] The high-temperature-resistant high-reflectivity coating is composed of components A and B, in parts by weight, wherein 1) the formula of component A is: epoxy-modified polysiloxane resin (viscosity 120cp, epoxy equivalent 120, 40 parts) , phenyl polysiloxane resin (35% phenyl content, 60 parts), high reflectivity coating powder (40 parts), nano fumed silica (particle size 14nm, 20 parts), barite powder (particle size 15μm, 20 parts), superfine flaky brass powder (particle size 5μm, 25 parts), BYK8461 (3 parts), xylene 10 parts, butyl acetate 14 parts; 2) B component is the molecular weight of 1000 Polysilazane (20 parts). The preparation process of the above-mentioned high-reflectivity coating powder is the same as that of Example 1.

[0099] The preparation process of component A of the high-temperature-resistant high-reflectance coating is the same as that in Example 1.

[0100] The construction technology of the high-temperature-resistant high-reflectivity coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com