Drying method of bamboo shoots

A bamboo shoot drying technology, applied in the field of bamboo shoot processing, can solve the problems of long drying cycle, narrow application area, and loss of nutrients in dried bamboo shoots, and achieve the effects of easy long-term storage, short production cycle, and fresh taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

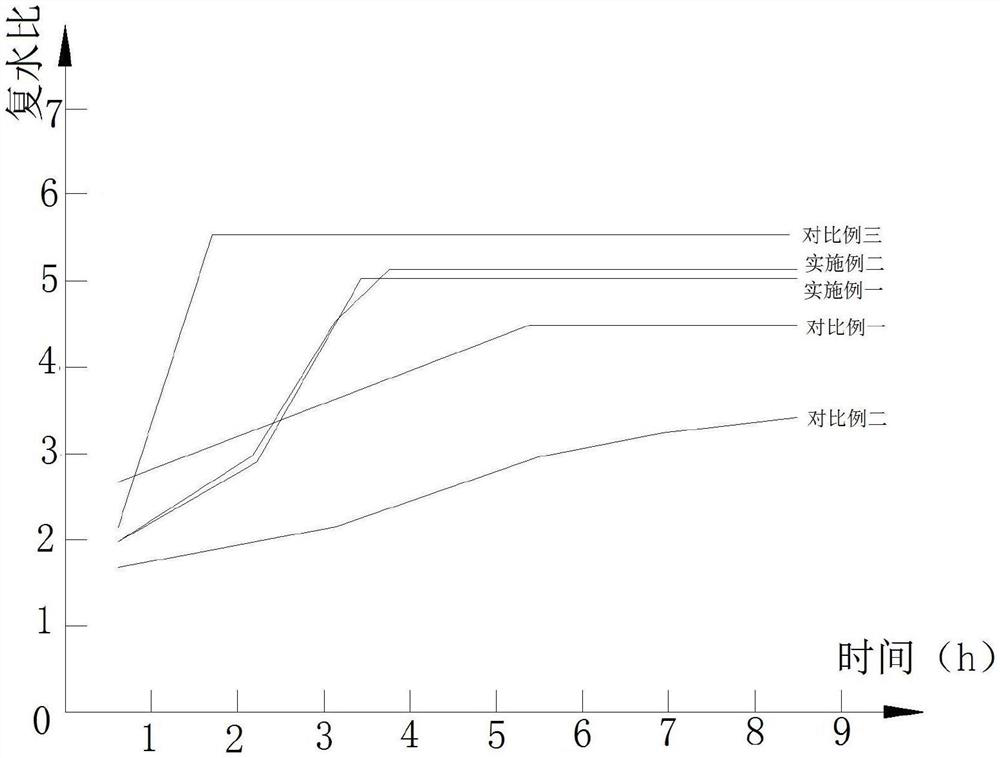

Image

Examples

Embodiment 1

[0029] In the present embodiment, dried bamboo shoots are obtained in the following manner:

[0030] Use local fresh moso bamboo shoots as raw materials for bamboo shoots. Cut the roots and peel the bamboo shoots obtained from the bamboo shoots, and then wash them with clean water. After cleaning, cut them in half and slice them. Lightly pat the surface of the cut bamboo shoots, so that the needles on the needle plate form pinholes on the surface of the cut bamboo shoots, and then use hot water to cook at high temperature, controlling the temperature of the hot water to 85-88°C , boiled for 210S, directly fished out after cooking, blanched in boiling water containing 3.5wt% edible alkali for 20S, fished out after rinsing, drained and spread to cool.

[0031] The above operation steps are completed within 24 hours after the raw materials of bamboo shoots are picked, so as to prevent the aging of the fibrous tissue in the bamboo shoots and affect the taste.

[0032] In this emb...

Embodiment 2

[0040] In the present embodiment, dried bamboo shoots are obtained in the following manner:

[0041]Use local fresh moso bamboo shoots as the raw material of bamboo shoots, cut the roots and peel the bamboo shoots obtained from the harvest, and then wash them with clean water. After cleaning, cut them in half and slice them. Lightly pat the surface of the cut bamboo shoots, so that the needles on the needle plate form pinholes on the surface of the cut bamboo shoots, and then use hot water to cook at high temperature, controlling the temperature of the hot water to 88-90°C , boil for 200S, take out directly after cooking, blanch in boiling water containing 3.5wt% edible alkali for 24S, take out after blanching and send it to a container for bleaching with a prefabricated bleaching solution, the prefabricated bleaching solution includes The mixture solvent prepared after mixing the chlorine dioxide of 25wt%, the benzoic acid peroxide of 17wt% and the sodium metabisulfite of 58w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com