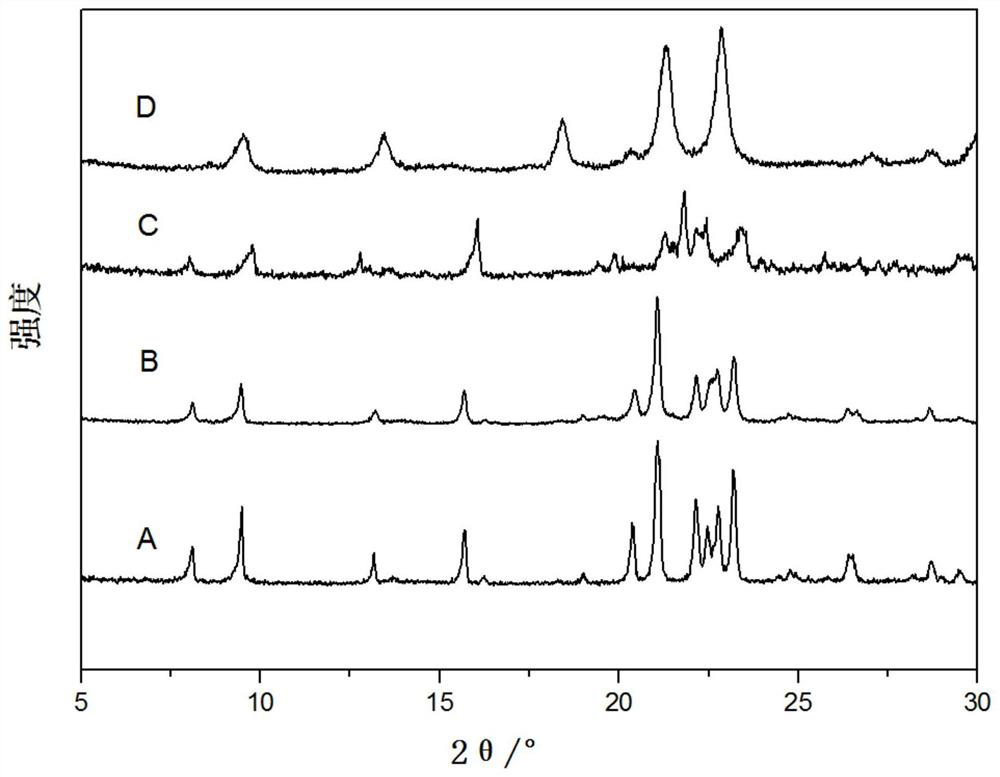

SAPO-11 molecular sieve and synthesis method thereof

A technology of SAPO-11, synthesis method, applied in molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate and other directions, can solve problems such as easy transformation of crystal structure, and achieve improved crystal morphology, simple synthesis process, and crystallite size. The effect of increasing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

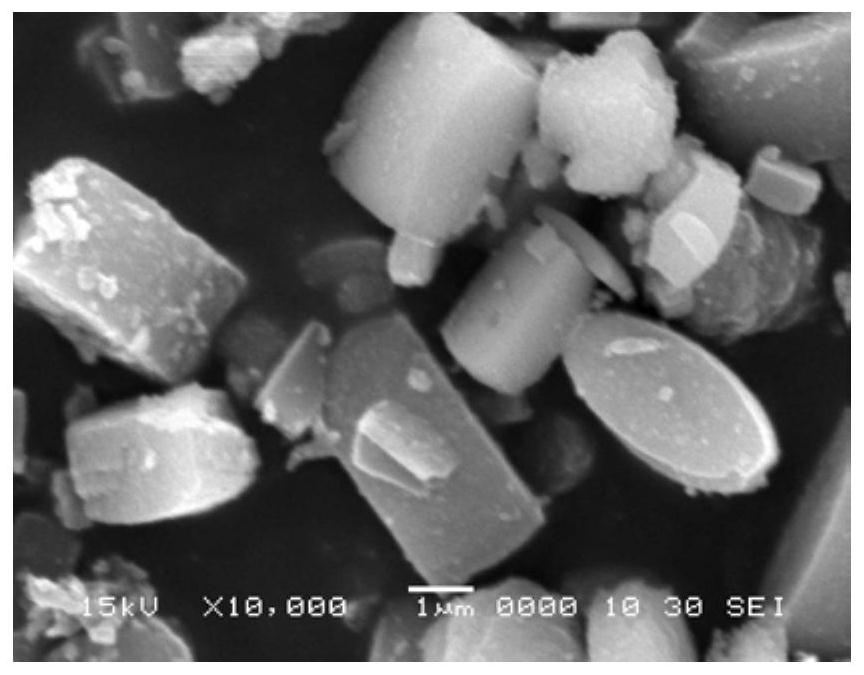

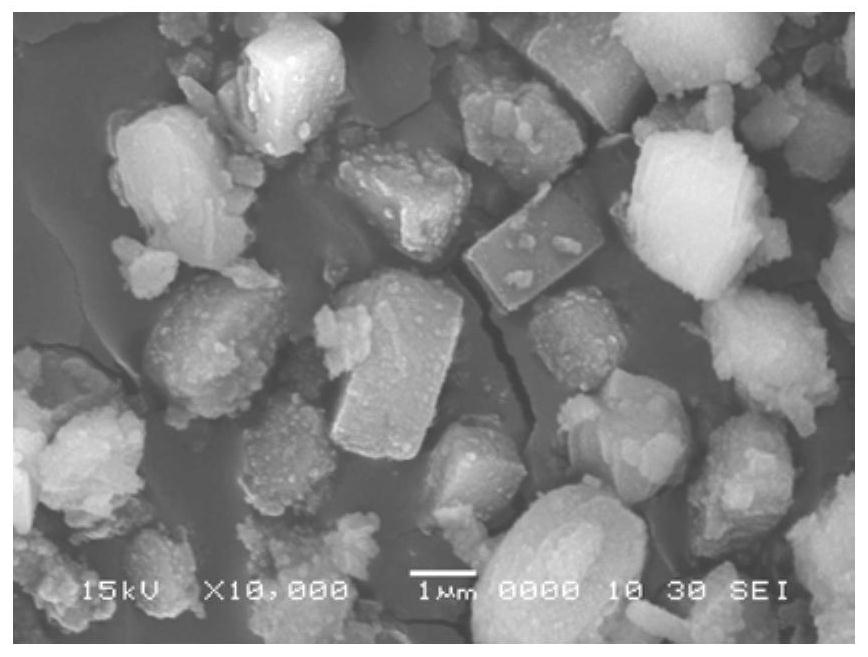

Embodiment 1

[0034] Preparation of the first step reaction mixture

[0035] 10.9 grams of pseudoboehmite (containing 75% Al 2 o 3 ) and 63.6 grams of deionized water were stirred evenly, and 18.5 grams of phosphoric acid (containing 85% H 3 PO 4 ), mixed and stirred for 2 hours; then 9.7 grams of di-n-propylamine (chemically pure) was added thereto, and continued to stir for 2 hours; next, 8 grams of silica sol (containing 30% SiO 2 ), fully stirred for 2 hours to form an initial reaction gel; finally, 1 gram of SAPO-11 molecular sieve powder was added to the initial reaction gel, and stirred evenly to form a reaction mixture.

[0036] The second step hydrothermal crystallization treatment

[0037] The reaction mixture was put into a stainless steel autoclave, and the temperature was kept at 110°C for 1 hour, at 120°C for 1 hour, at 130°C for 1 hour, and at 200°C for 24 hours to carry out the hydrothermal crystallization reaction. After the crystallized product was filtered and washed...

Embodiment 2

[0041] 10.9 grams of pseudoboehmite (containing 75% Al 2 o 3 ) and 63.6 grams of deionized water were stirred evenly, and 18.5 grams of phosphoric acid (containing 85% H 3 PO 4 ), mixed and stirred for 2 hours; then 5 grams of di-n-propylamine (chemically pure) was mixed with 4.7 grams of diisopropylamine (chemically pure) and added thereto, and continued to stir for 2 hours; then add 8 grams of silica sol (containing 30% SiO 2 ), fully stirred for 2 hours to form an initial reaction gel; finally, 1 gram of SAPO-11 molecular sieve powder was added to the initial reaction gel, and stirred evenly to form a reaction mixture.

[0042] The reaction mixture was put into a stainless steel autoclave, and the temperature was kept at 110°C for 2 hours, at 120°C for 2 hours, at 130°C for 2 hours, and at 160°C for 24 hours to carry out the hydrothermal crystallization reaction. After the crystallized product was filtered and washed, it was dried at 120° C. and weighed to obtain 19.2 gr...

Embodiment 3

[0059] The calcined SAPO-11 molecular sieve obtained in Example 1-2 and Comparative Example 1-2 was loaded with 0.5% Pt to prepare a catalyst, which was pressed into tablets and sieved into 40-60 mesh samples. The catalyst numbers were catalyst 1 and catalyst 2 respectively. , Catalyst 3, and Catalyst 4, to investigate their catalytic effects in the isomerization reaction process of n-dodecane. Evaluation conditions are reaction pressure 2MPa, space velocity 1.0h -1 , the molar ratio of hydrogen to hydrocarbon is 12:1, and the reaction results are shown in Table 1.

[0060] Table 1

[0061]

[0062]

[0063] It can be seen from Table 1 that compared with the traditional three-stage hydrothermal synthesis method, the SAPO-11 molecular sieve prepared by the four-stage crystallization method showed higher reactivity in the hydroisomerization reaction of n-dodecane And isomer selectivity, the yield of dodecane isomers reaches more than 80%, and has more excellent isomeriza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com