SMC (Sheet Molding Compound) composite sheet for hog house slatted plate and preparation method of SMC composite sheet

A composite sheet and slatted board technology, applied in the field of composite materials, can solve the problems of poor thermal conductivity, heavy weight, high production cost, etc., achieve good mechanical strength and thermal conductivity, reduce self-weight, and facilitate cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

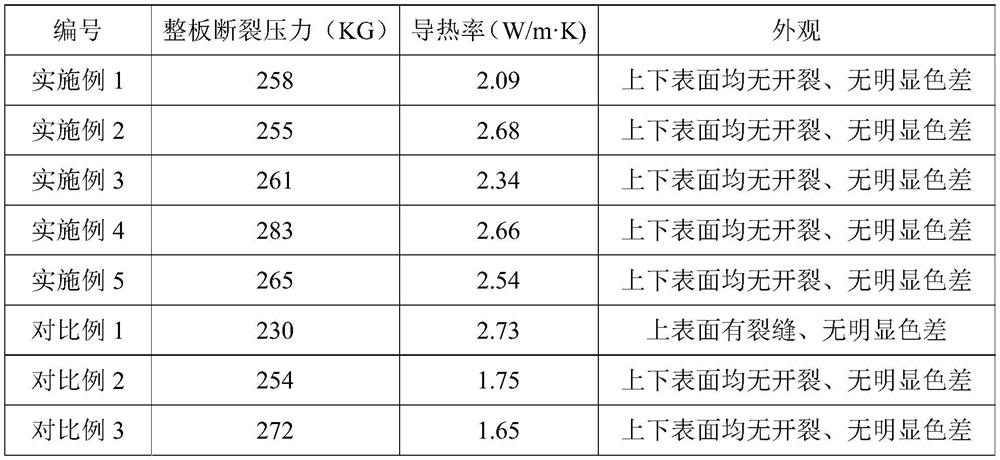

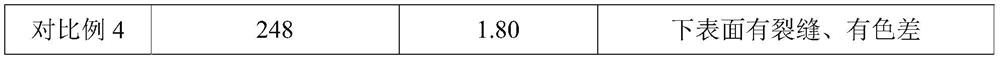

Examples

preparation example Construction

[0038] The present invention also provides a preparation method of the SMC composite sheet used for the slatted slats in a pig house, comprising the following steps:

[0039] Step 1: disperse the nano-alumina evenly in the polyethylene glycol solution and remove the solvent to obtain the polyethylene glycol-modified nano-alumina;

[0040] Step 2: According to the proportion, add p-benzoquinone, styrene and permeable benzene to the o-phenyl unsaturated polyester resin and mix evenly, continue to add tert-butyl peroxybenzoate, polyethylene glycol modified nano-alumina, fill Agent, thickener and release agent continue to mix uniformly to obtain polyester resin paste;

[0041] Step 3: Mix the glass fiber and the heat-conducting fiber evenly, and use polyester resin paste to impregnate the mixed fiber, age it, and mold it to obtain an SMC composite sheet.

[0042] In the above technical solution, the polyethylene glycol-modified nano-alumina is mixed with the polyester resin as th...

Embodiment 1

[0047] Formula: 25 parts of propylene phthalate unsaturated polyester resin, 3 parts of styrene, 6 parts of permeable benzene, 0.2 parts of tert-butyl peroxybenzoate, 0.005 parts of p-benzoquinone, 16 parts of glass fiber, polyethylene glycol 5 parts of coated modified nano-alumina, 7 parts of graphene fibers, 8 parts of stone powder, 12 parts of magnesium oxide, 2 parts of zinc stearate and 1 part of green color paste;

[0048] Its preparation method comprises the following steps:

[0049] The nano-alumina is uniformly dispersed in the PEG400 aqueous solution with a mass concentration of 8%, the mass ratio of PEG400 and nano-alumina is 1:2, and the solvent is removed to obtain polyethylene glycol-modified nano-alumina, which is used for later use.

[0050] According to the proportion, add p-benzoquinone, styrene and permeable benzene to the o-phenyl unsaturated polyester resin and mix evenly, and continue to add tert-butyl peroxybenzoate, polyethylene glycol modified nano-alu...

Embodiment 2

[0052] Formula: 30 parts of propylene phthalate unsaturated polyester resin, 3.6 parts of styrene, 7.2 parts of permeable benzene, 0.5 parts of tert-butyl peroxybenzoate, 0.02 parts of p-benzoquinone, 20 parts of glass fiber, polyethylene glycol 8 parts of coated modified nano-alumina, 10 parts of graphene fibers, 8 parts of stone powder, 20 parts of magnesium oxide, 5 parts of zinc stearate and 1 part of green color paste;

[0053] The preparation method is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com