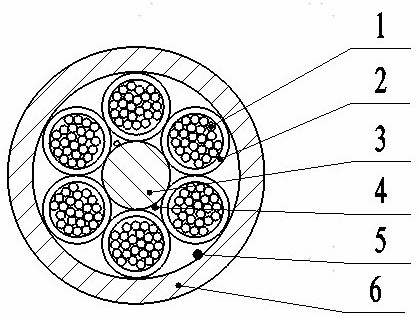

Water-blocking flexible optical fiber ribbon and full-dry high-density optical cable

A technology of optical fiber ribbon and water blocking, which is applied in the field of optical communication, can solve the problems of unfavorable optical cable miniaturization, etc., and achieve the effects of weight reduction, reduction of bending loss increase, and small light attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0052] The concrete formula of embodiment 3 is as follows:

[0053] Acrylate prepolymer 35wt%, acrylate monomer 26.5wt%, thickener 3wt%, additive 1.5wt%, photoinitiator 4wt%, pigment 6%, sodium polyacrylate 24wt%

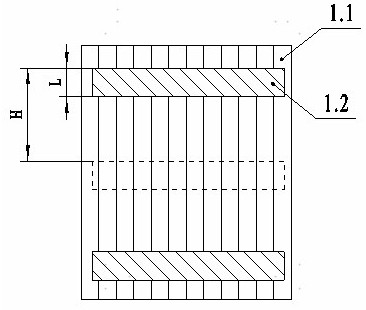

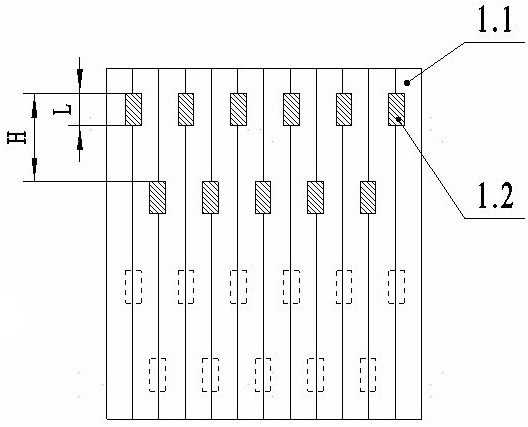

[0054] The microbending sensitivity of the single-core optical fiber is ≤2dB / km@1550nm, and the additional attenuation at -30~+70°C is ≤0.05dB / km@1550nm. The outer coating layer of the single-core optical fiber is contacted and bonded to the resin connection part. The resin connection part has different colors according to the position of the optical fiber to which it is bonded in the water-blocking flexible optical fiber ribbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com