Sake imitation prepared from single component

A technology for imitation and sake, which is applied in the field of sake imitation prepared from a single component, which can solve the problems of time-consuming, high cost, and harsh harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

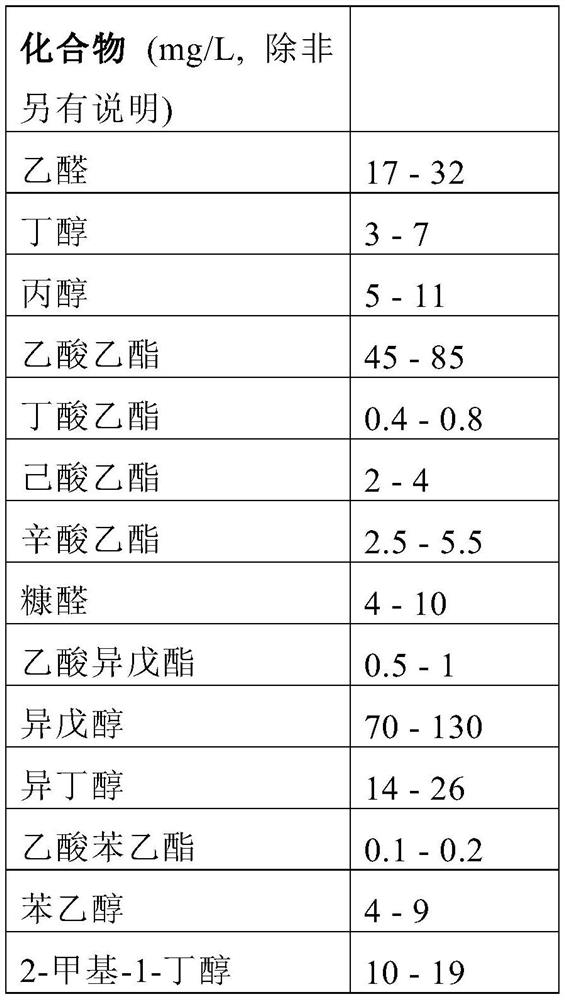

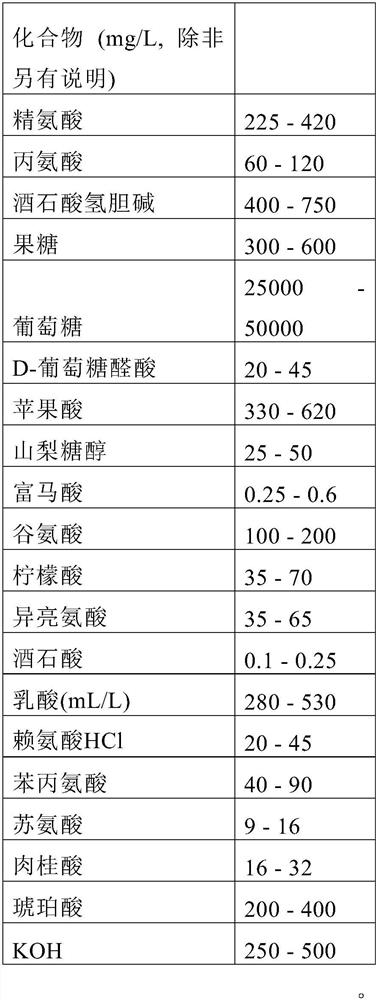

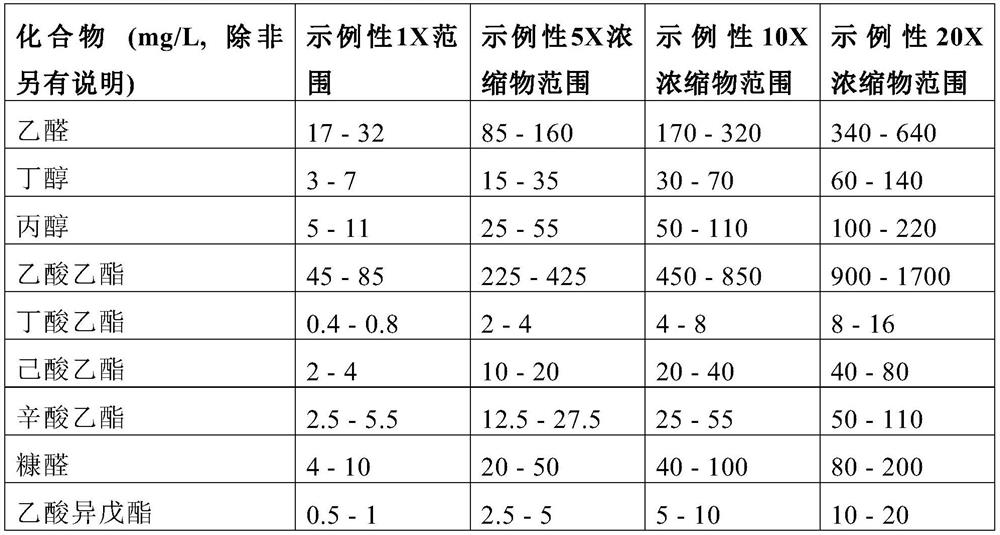

[0283] Embodiment 1 is a sake replica comprising:

[0284] ethanol;

[0285] water; and

[0286] One or more additional volatile organic compounds (VOCs), wherein the one or more additional VOCs include at least one compound selected from the group consisting of 1,4-cineole, 1-decanol, 2 ,4,6-trimethylphenol, 2-acetyl-1-methylpyrrole, 2-ethyl-3(5 or 6)-dimethylpyrazine, 2-ethyl-3-methylpyrazine , 2-isopropyl-4-methylthiazole, 2-methoxy-3-(1-methylpropyl)pyrazine, 2-methoxy-4-methylphenol, 2-methoxy- 4-Propylphenol, 2-methylbutyl acetate, 2-methylbutyl isovalerate, 2-nonanol, 3-carene, 3-methylthiohexyl acetate, 3-phenylpropanal, 4,5,6,7-tetrahydro-3,6-dimethylbenzofuran, 4-terpineol, 4-mercapto-4-methyl-2-pentanone, 5-methyl-2-benzene 2-hexenal, acetoin, α-ionone, allyl heptanoate, α-pinene, amyl alcohol, amyl butyrate, anisyl acetate, anisyl butyrate, b-caryophyllene, Benzyl Acetate, Benzyl Benzoate, Benzyl Butyrate, Benzyl Formate, Benzyl Propionate, β-Ionone, Butyryl L...

Embodiment approach 2

[0287] Embodiment 2 is the sake replica according to embodiment 1, wherein the one or more additional VOCs do not include at least one compound selected from the group consisting of 2,3-pentanedione, 1-octanol, 2 -Heptanone, 2-Nanone, 5-Methylfurfural, Benzaldehyde, Benzyl Alcohol, Butyl Acetate, Butyraldehyde, Citronellol, Diethyl Succinate, Ethyl Isobutyrate, Ethyl Lactate, Propionic Acid Ethyl ester, ethyl trans-2-butenoate, ethyl (methylthio)acetate, γ-enantholactone, γ-caprolactone, γ-octyl lactone, hexanol, isopentyl caproate, Isobutyl acetate, isobutyraldehyde, isobutyric acid, isovaleric acid, methionoacetate, methyl acetate, nonanoic acid, phenylacetaldehyde, propionaldehyde, propionic acid, propyl acetate, and propyl butyrate .

Embodiment approach 3

[0288]Embodiment 3 is a sake replica comprising:

[0289] ethanol;

[0290] water; and

[0291] One or more additional VOCs, wherein the one or more additional VOCs do not include at least one compound selected from the group consisting of 1-octanol, 2,3-pentanedione, 2-heptanone, 2-Nanone, 5-Methylfurfural, Benzaldehyde, Benzyl Alcohol, Butyl Acetate, Butyraldehyde, Citronellol, Diethyl Succinate, Ethyl Isobutyrate, Ethyl Lactate, Ethyl Propionate, Trans Formula - 2-butenoic acid ethyl ester, (methylthio) ethyl acetate, γ-enantholactone, γ-caprolactone, γ-octyl lactone, hexanol, isoamyl caproate, isobutyl acetate , Isobutyraldehyde, Isobutyric Acid, Isovaleric Acid, Methionyl Acetate, Methyl Acetate, Nonanoic Acid, Phenylacetaldehyde, Propionaldehyde, Propionic Acid, Propyl Acetate, and Propyl Butyrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com