High-barrier pesticide packaging bottle and preparation method thereof

A packaging bottle and high barrier technology, which is applied in the field of pesticide packaging plastics, can solve the problem that the gas barrier performance of pesticide packaging bottles cannot meet the high barrier performance of pesticide bottles, and achieve good gas barrier performance, low production cost and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

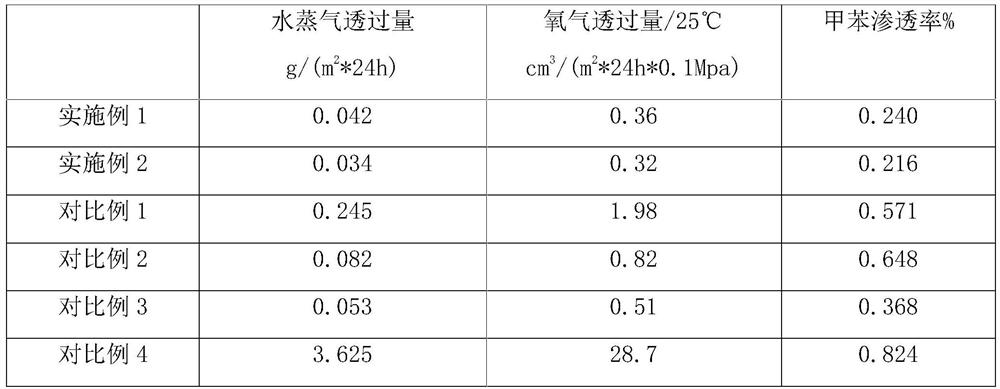

Examples

preparation example 1

[0035] The barrier layer is a three-layer co-extruded high barrier composite film with a thickness of 50 microns. The three-layer co-extruded high-barrier composite film is composed of a 15-micron first modified PET film, a 20-micron intermediate reinforced barrier film, and a 15-micron second modified PET film. Both the first modified PET film and the first modified PET film are prepared from the following raw materials in mass percentage: 2% TPEE thermoplastic polyester elastomer (DuPont TPEE-5526), 20% polyethylene naphthalate Alcohol resin (brand name TN8065S, American DuPont Company), 1% antioxidant 1010, 77% PET resin (brand name: RE19045BK, American DuPont Company).

[0036] The intermediate reinforced barrier film is prepared from the following raw materials: 3% TPEE thermoplastic polyester elastomer (DuPont TPEE-5526), 20% LCP resin (grade A950, Celanese Corporation), 15% polynaphthalene Formic acid ethylene glycol resin (brand name TN8065S, U.S. DuPont Company),...

preparation example 2

[0045] The difference between Preparation Example 2 and Preparation Example 1 is:

[0046] The intermediate reinforced barrier film is prepared from the following raw materials: 3% TPEE thermoplastic polyester elastomer (DuPont TPEE-5526), 25% LCP resin (grade A950, Celanese Corporation), 17% polynaphthalene Formic acid ethylene glycol resin (brand name TN8065S, U.S. DuPont Company), 49% PET resin (brand name: RE19045BK, U.S. DuPont Company), 1.0% antioxidant 1010, 2% barium sulfate (particle size: 12500 mesh, CAS number: 7727-43 -7, Zhushan County Qinba Barium Salt Co., Ltd.), 1.6% white carbon black (Lingshou County Ruojia Mineral Products Co., Ltd., 5000 mesh), 0.4% zinc oxide whiskers (model JC-83-02, Shijiazhuang Tuochuang Chemical Products Sales Co., Ltd.), 1% polyvinyl alcohol.

preparation example 3

[0048] The difference between Preparation Example 3 and Preparation Example 1 is:

[0049] The intermediate reinforced barrier film is prepared from the following raw materials: 3% TPEE thermoplastic polyester elastomer (DuPont TPEE-5526), 91% PET resin (brand: RE19045BK, DuPont, USA), 1.0% antioxidant 1010, 2% barium sulfate (particle size: 12500 mesh, CAS number: 7727-43-7, Zhushan County Qinba Barium Salt Co., Ltd.), 1.6% white carbon black (Lingshou County Ruojia Mineral Products Co., Ltd., 5000 mesh), 0.4 % zinc oxide whiskers (model JC-83-02, Shijiazhuang Tuochuang Chemical Products Sales Co., Ltd.), 1% polyvinyl alcohol.

[0050] The preparation method of barrier layer comprises the following steps:

[0051] Step 1, preparation of modified PET resin and intermediate reinforced barrier resin;

[0052] Preparation of modified PET resin: 2.0kg polyethylene naphthalate resin and 7.7kg PET resin were dried in a drier at 120°C for 4 hours, then the dried polyethylene naph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com