Nano silicon dioxide grafted halamine antibacterial melt-blown material as well as preparation method and application thereof

A nano-silica, silicon dioxide technology, applied in rayon manufacturing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of difficult release of halogen elements, potential safety hazards, poor antibacterial effect, etc., and achieve electrostatic charge High content, improved filtration effect, antibacterial content is not easy to lose the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030]The invention provides a preparation method of nano-silica grafted haloamine antibacterial melt-blown material, comprising the following steps:

[0031] S1. Preparation of modified silica:

[0032] The volume ratio of isopropanol and water is (2-5): 1 to form a mixed solution, and the γ-mercaptopropyltrimethoxysilane coupling agent is added to the mixed solution for hydrolysis to form a silanol structure. Then, hydrophilic nano silicon dioxide is added to the obtained solution, and after ultrasonic dispersion for 20-50 minutes, it is heated to reflux at 75-85°C. Finally, the mixed solution is centrifuged and washed, and the centrifuged product is vacuum-dried to obtain modified silicon dioxide.

[0033] Wherein, the mass ratio of hydrophilic nano silicon dioxide and γ-mercaptopropyltrimethoxysilane coupling agent is (8-12):(1-5).

[0034] In this process, hydrophilic silica is used, and its hydrophilicity is used to uniformly disperse it in the mixed solution containin...

Embodiment 1

[0056] A preparation method of nano silicon dioxide grafted haloamine antibacterial melt-blown material, comprising the following steps:

[0057] S1. Preparation of modified silica:

[0058] Prepare isopropanol and water at a volume ratio of 3:1 to form a mixed solution, and add γ-mercaptopropyltrimethoxysilane coupling agent into the prepared mixed solution for hydrolysis to form a silanol structure. Then, hydrophilic nano silicon dioxide was added to the obtained solution, and after ultrasonic dispersion for 30 min, it was heated to reflux at 80°C. Finally, the mixed solution is centrifuged and washed, and the centrifuged product is vacuum-dried to obtain modified silicon dioxide.

[0059] Wherein, the mass ratio of hydrophilic nano silicon dioxide and γ-mercaptopropyltrimethoxysilane coupling agent is 10:3.

[0060] S2. Preparation of silica grafted N-halamine precursor powder:

[0061] Mix the modified nano-silica, 1-allylhydantoin and benzoin dimethyl ether prepared in...

Embodiment 2-3

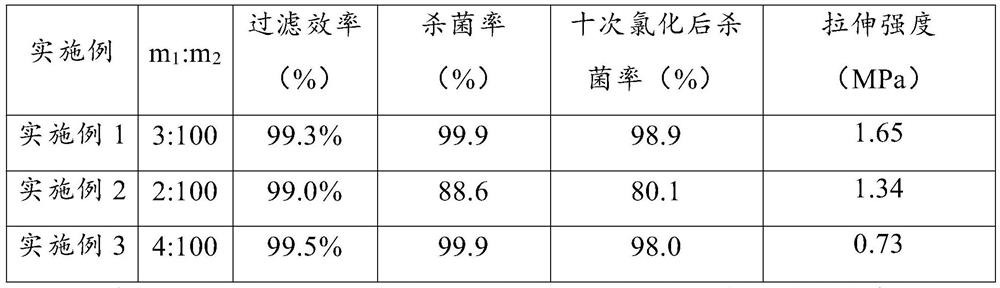

[0073] A kind of preparation method of nano-silica grafted halide amine antibacterial melt-blown material, compared with embodiment 1, the difference is that in step S3, nano-silica grafted N-halamine precursor powder and melt Mass ratio of sprayed polypropylene resin m 1 :m 2 It is different, and the others are substantially the same as those in Embodiment 1, and will not be repeated here.

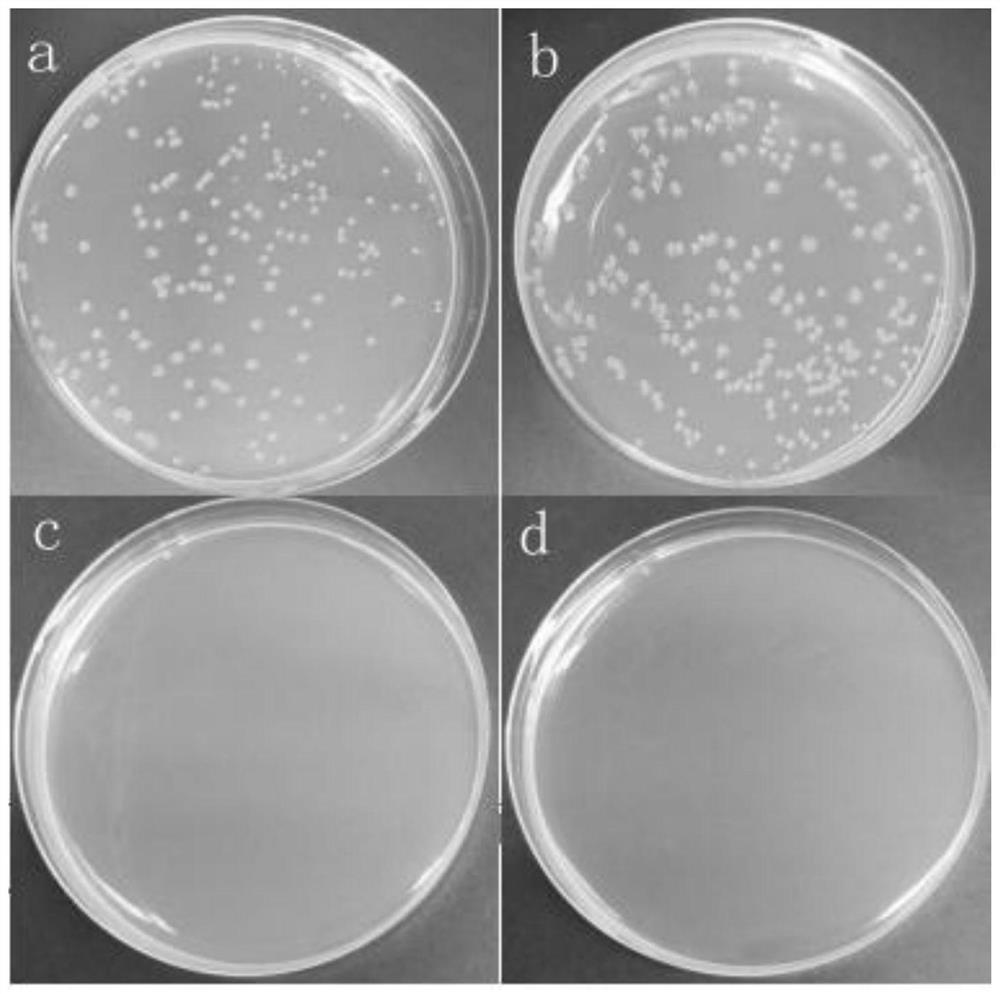

[0074] The nano-silica grafted haloamine antibacterial melt-blown material prepared in Examples 1-3 is subjected to a performance test, and the results are shown in Table 1. The bactericidal rate refers to the bactericidal rate of Escherichia coli, and the filtration efficiency refers to the bactericidal rate after chlorinated electret. Filtration efficiency of melt-blown material (without repeated regeneration) for 0.3 μm sodium chloride aerosol:

[0075] The performance test of the nano silicon dioxide grafted haloamine antibacterial melt-blown material prepared by table 1 embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com