Method for preparing NiCo hydrotalcite/foamed nickel composite material by taking Co-MOF as sacrificial template

A technology of composite materials and nickel foam, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of reducing the capacitance performance of active materials, poor conductivity of hydrotalcite, and poor conductivity, so as to improve conductivity and large The effect of specific surface area and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

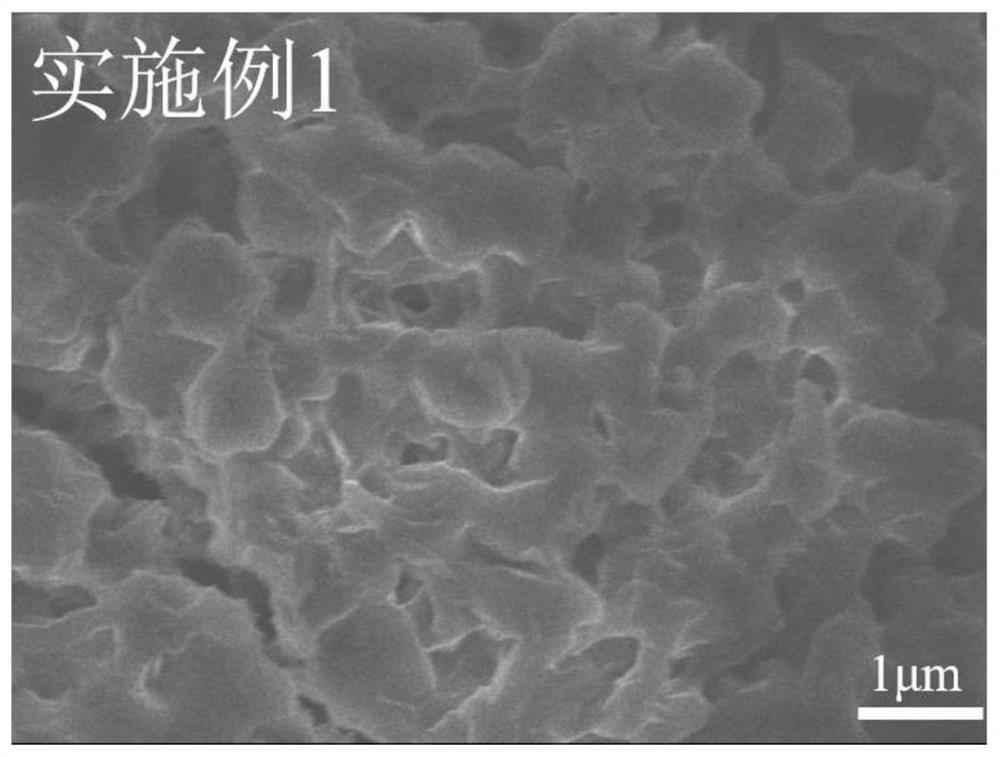

Embodiment 1

[0029] (1) Foam nickel pretreatment: the foam nickel is cut to an area of 2cm 2 Rectangular nickel foam, first place the cut nickel foam in acetone solution for 3 minutes, then use 1M HCl for 4 minutes, and finally use absolute ethanol for 5 minutes, and dry it in an oven at 60°C for 12 hours;

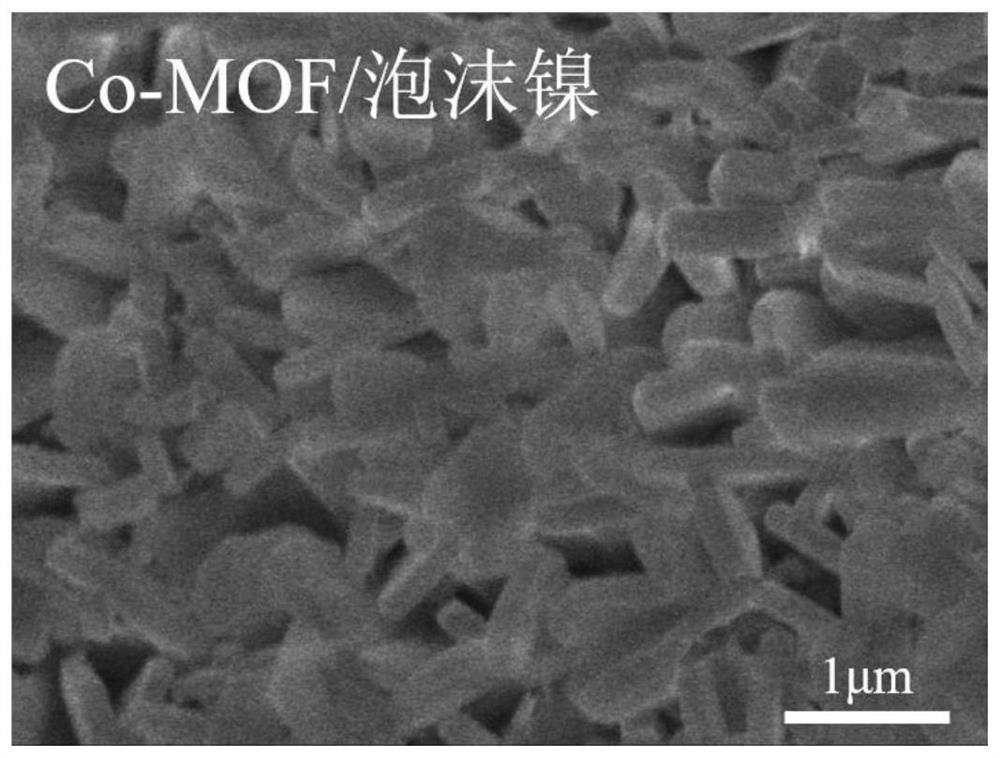

[0030] (2) Precursor Co-MOF / nickel foam preparation: Dissolve 3mmol cobalt nitrate in 60ml deionized water, and stir magnetically at a speed of 500rpm for 10min; dissolve 24mmol 2-methylimidazole in 60ml deionized water, Rotating speed is carried out magnetic stirring 10min; 2-methylimidazole solution is poured in the cobalt nitrate solution, forms mixed solution, mixed solution is carried out magnetic stirring 15min with the rotating speed of 800rpm; The foamed nickel that pretreated is placed in mixed solution, and The mixed solution was left standing or stirred at a speed not greater than 500 rpm for 8 hours at a temperature of 25°C. The nickel foam grown on Co-MOF was repeatedly...

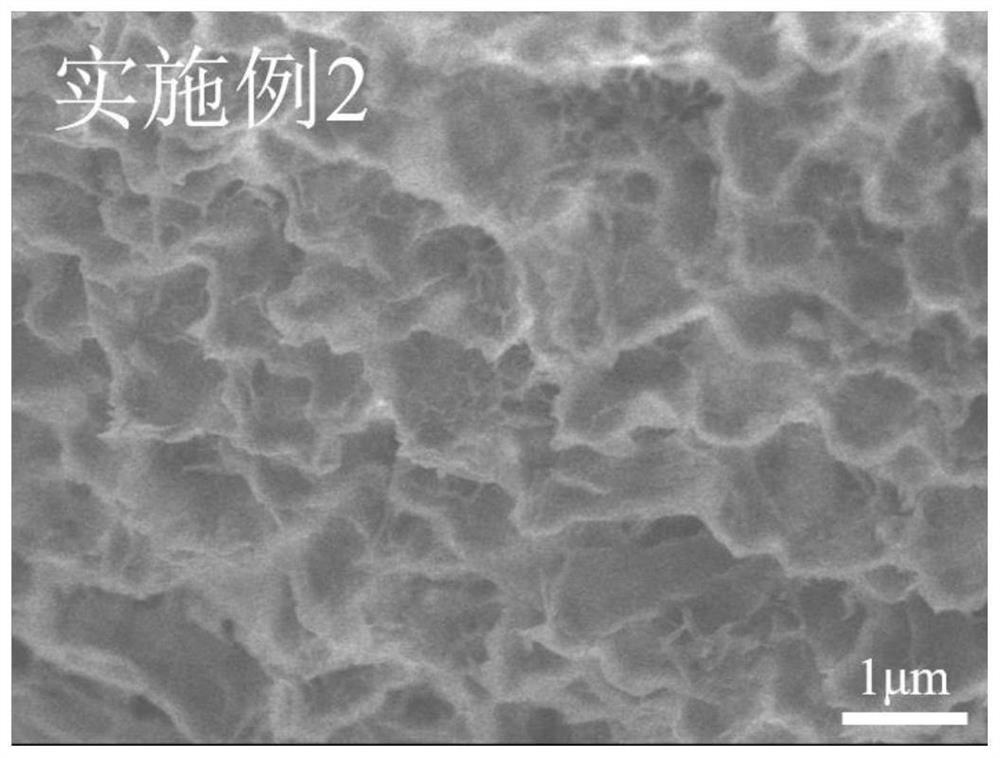

Embodiment 2

[0034] (1) Foam nickel pretreatment: the foam nickel is cut to an area of 2cm 2 Rectangular nickel foam, first place the cut nickel foam in acetone solution for 3 minutes, then use 1M HCl for 4 minutes, and finally use absolute ethanol for 5 minutes, and dry it in an oven at 60°C for 12 hours;

[0035] (2) Precursor Co-MOF / nickel foam preparation: Dissolve 3mmol cobalt nitrate in 60ml deionized water, and stir magnetically at a speed of 500rpm for 10min; dissolve 24mmol 2-methylimidazole in 60ml deionized water, Rotating speed is carried out magnetic stirring 10min; 2-methylimidazole solution is poured in the cobalt nitrate solution, forms mixed solution, mixed solution is carried out magnetic stirring 15min with the rotating speed of 800rpm; The foamed nickel that pretreated is placed in mixed solution, and The mixed solution was left standing or stirred at a speed not greater than 500 rpm for 8 hours at a temperature of 25°C. The nickel foam growing Co-MOF was cleaned wit...

Embodiment 3

[0039] 1) Pretreatment of foamed nickel: cutting the foamed nickel to an area of 2cm 2 Rectangular nickel foam, first place the cut nickel foam in acetone solution for 3 minutes, then use 1M HCl for 4 minutes, and finally use absolute ethanol for 5 minutes, and dry it in an oven at 60°C for 12 hours;

[0040] 2) Precursor Co-MOF / nickel foam preparation: Dissolve 3mmol cobalt nitrate in 60ml deionized water and stir magnetically at 500rpm for 10min; dissolve 24mmol 2-methylimidazole in 60ml deionized water and stir at 500rpm Perform magnetic stirring for 10 min; pour 2-methylimidazole solution into cobalt nitrate solution to form a mixed solution, and magnetically stir the mixed solution at a speed of 800 rpm for 15 min; place the pretreated nickel foam in the mixed solution, and mix The solution was left standing or stirred at a speed not greater than 500 rpm for 8 hours at a temperature of 25°C. The nickel foam grown on Co-MOF was treated with deionized water and dried in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com