System and method for treating anthraquinone process hydrogen peroxide production wastewater by electrolytic flocculation method

An anthraquinone method hydrogen peroxide, electrolytic flocculation technology, applied in the direction of flocculation/sedimentation water/sewage treatment, biological water/sewage treatment, water/sewage treatment, etc. Cumbersome and other problems, to achieve the effect of short residence time, low investment cost and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and exemplary embodiments.

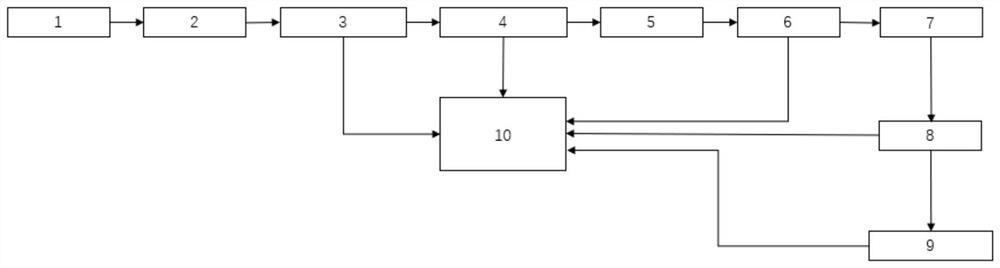

[0032] refer to figure 1 , an electrolytic flocculation method for treating anthraquinone hydrogen peroxide production wastewater treatment system, including a sludge storage tank 10, and an oil separation buffer pool 1, a wastewater adjustment pool 2, an electrolytic flocculation equipment 3, and a coagulation sedimentation equipment 4 arranged in sequence , an intermediate pool 5, an air flotation machine 6, a clear water pool 7, an A / O reaction pool 8 and a membrane bioreactor 9.

[0033] Process wastewater is wastewater produced by anthraquinone hydrogen peroxide, and other wastewater is wastewater without oil slick and COD95%, the removal rate of suspended oil is 97%, the COD removal rate is >85%, the phosphorus removal rate is >80%, and the nitrogen removal rate is >40%. Ammonia nitrogen removal rate > 40%; coagulation sedimentation equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com