High-strength and multi-morphology Al2O3 particle/Al2O3 fiber composite ceramic sheet and preparation method thereof

A ceramic sheet and fiber composite technology, which is applied in the field of composite ceramic sheets, can solve the unsolved problems of mechanical strength and poor green formability, and achieve the effects of inhibiting disordered migration, high brittleness, and suppressing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

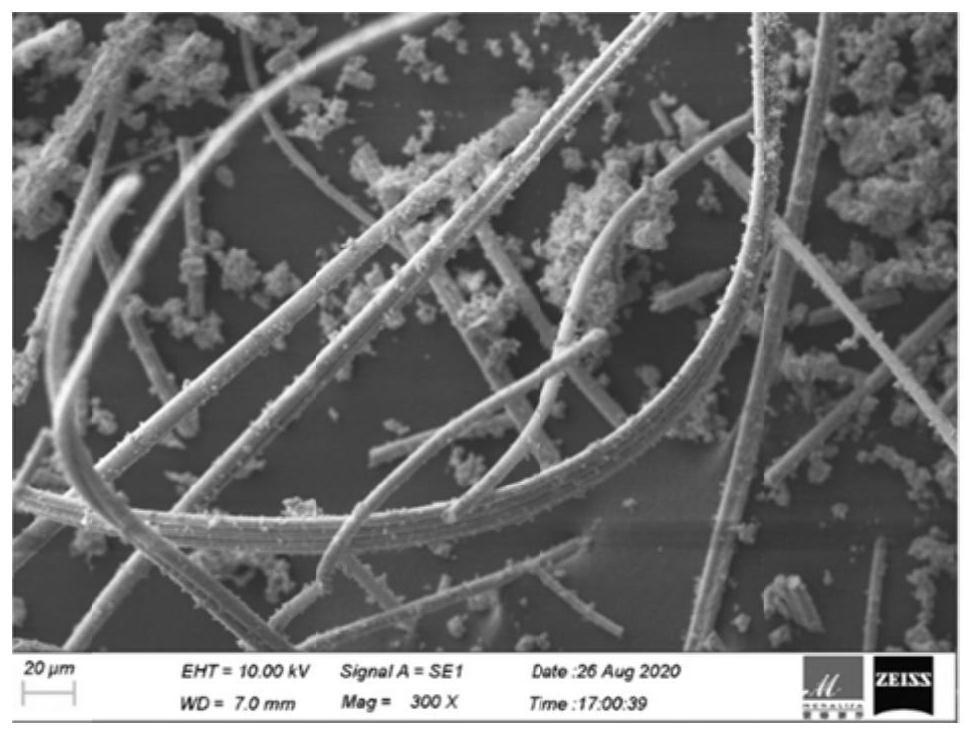

[0040] The specific technical scheme is as follows: a high-strength multi-morphology Al 2 o 3 Particle / Al 2 o 3 A preparation method for a fiber composite ceramic sheet, comprising the steps of:

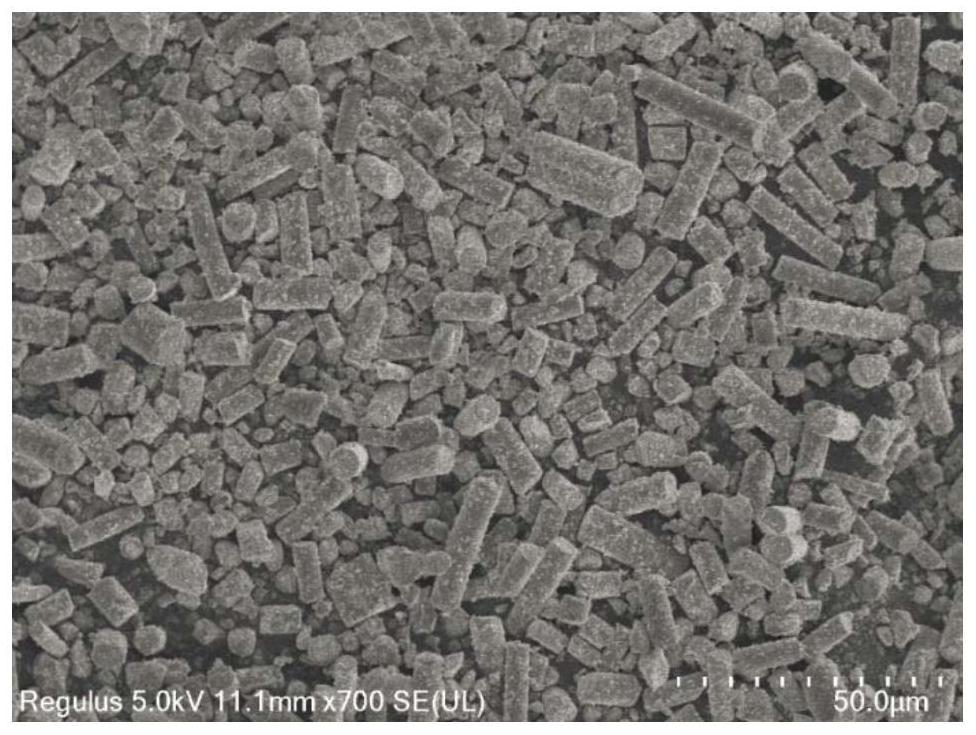

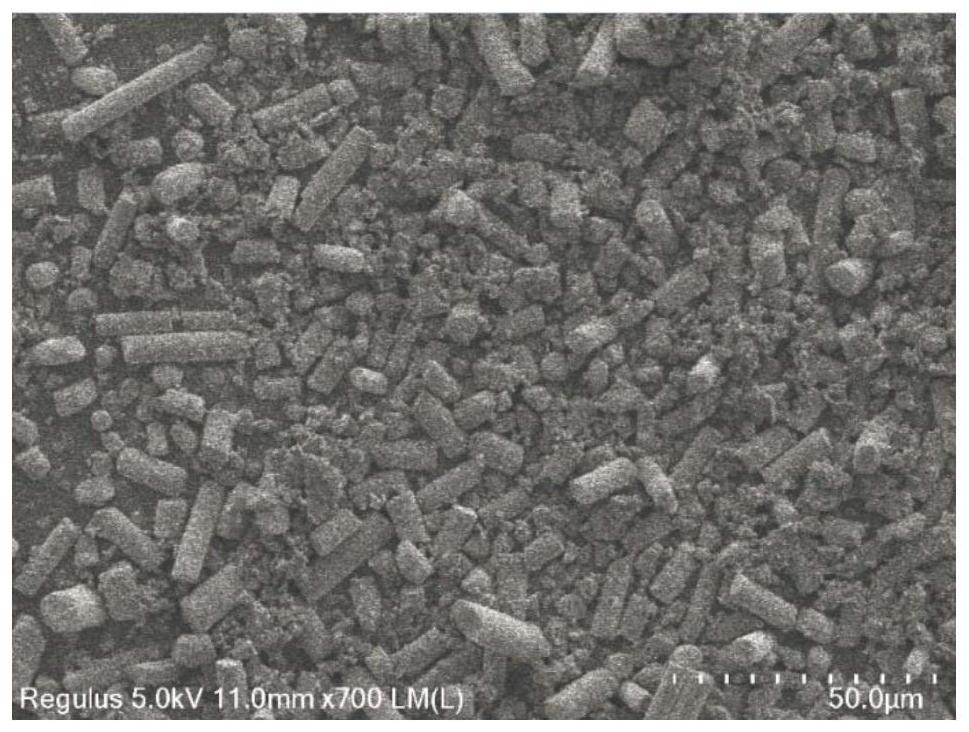

[0041] 1) Spherical and rod-shaped Al 2 o 3 The powders are weighed sequentially according to a specific mass ratio and mixed uniformly to obtain Al 2 o 3 Mix powder A. Among them, spherical Al 2 o 3 The particle diameter of the powder is 100-200nm, the mesopore diameter is 1-5nm, and the mesoporosity is 5%-10%. Rod Al 2 o 3 The particle size of the powder is 1-5 μm, the mesopore diameter is 50-100 nm, and the mesoporosity is 10%-20%. The specific mass ratio above is spherical Al 2 o 3 Powder: Rod Al 2 o 3 Powder=(20-30):(5-10).

[0042] 2) Take Al 2 o 3 Mix powder A, magnesium oxide, manganese oxide, high-strength cement soil, high-quality potassium feldspar, kaolin, black talc, Shaoguan ball clay, xenotime soil, carboxymethyl cellulose, sodium tripolyphosphate 11...

Embodiment 1

[0048] 1) Spherical and rod-shaped Al 2 o 3 The powders are weighed sequentially according to a specific mass ratio and mixed uniformly to obtain Al 2 o 3 Mix powder A. Among them, spherical Al 2 o 3 The particle size of the powder is 100nm, the mesopore diameter is 1nm, and the mesoporosity is 5%. Rod Al 2 o 3 The particle size of the powder is 1 μm, the mesopore diameter is 50 nm, and the mesoporosity is 10%. The specific mass ratio above is spherical Al 2 o 3 Powder: Rod Al 2 o 3 Powder = 20:5.

[0049] 2) Take Al 2 o 3 Mix powder A, magnesium oxide, manganese oxide, high-strength cement soil, high-quality potassium feldspar, kaolin, black talc, Shaoguan ball clay, xenotime soil, carboxymethyl cellulose, sodium tripolyphosphate 11 kinds of raw materials, according to the following Stoichiometric weighing and uniform mixing, and then crushing, ball milling, pulping and other processes to obtain the slurry precursor B with good suspension. where Al 2 o 3 The...

Embodiment 2

[0054] 1) Spherical and rod-shaped Al 2 o 3 The powders are weighed sequentially according to a specific mass ratio and mixed uniformly to obtain Al 2 o 3 Mix powder A. Among them, spherical Al 2 o 3 The particle diameter of the powder is 200nm, the mesopore diameter is 5nm, and the mesoporosity is 10%. Rod Al 2 o 3 The particle size of the powder is 5 μm, the mesopore diameter is 100 nm, and the mesoporosity is 20%. The specific mass ratio above is spherical Al 2 o 3 Powder: Rod Al 2 o 3 Powder = 30:10.

[0055] 2) Take Al 2 o 3 Mix powder A, magnesium oxide, manganese oxide, high-strength cement soil, high-quality potassium feldspar, kaolin, black talc, Shaoguan ball clay, xenotime soil, carboxymethyl cellulose, sodium tripolyphosphate 11 kinds of raw materials, according to the following Stoichiometric weighing and uniform mixing, and then crushing, ball milling, pulping and other processes to obtain the slurry precursor B with good suspension. Among them, A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com