Method for detecting triethylamine and N, N-diethylaniline in ceftazidime and application

A technology of diethylaniline and ceftazidime, which can be used in measurement devices, instruments, scientific instruments, etc., can solve the problem of limited types of residual solvents, and achieve the effects of good system adaptability, good linearity, and good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

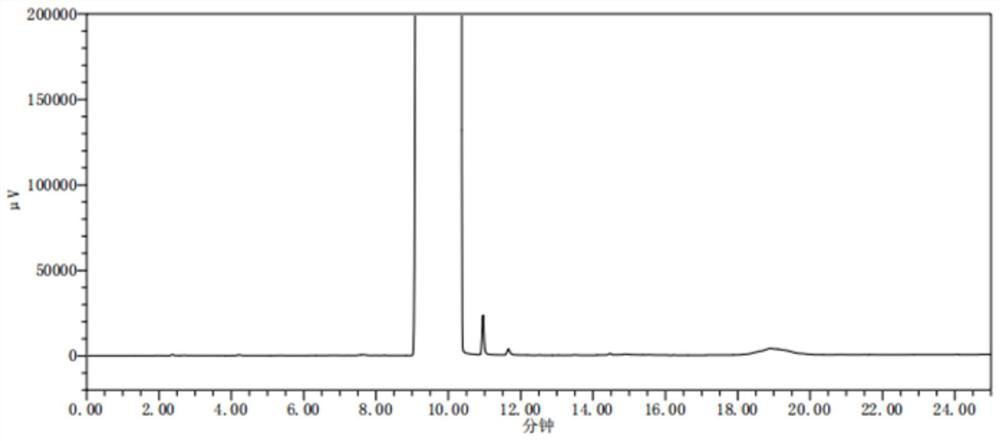

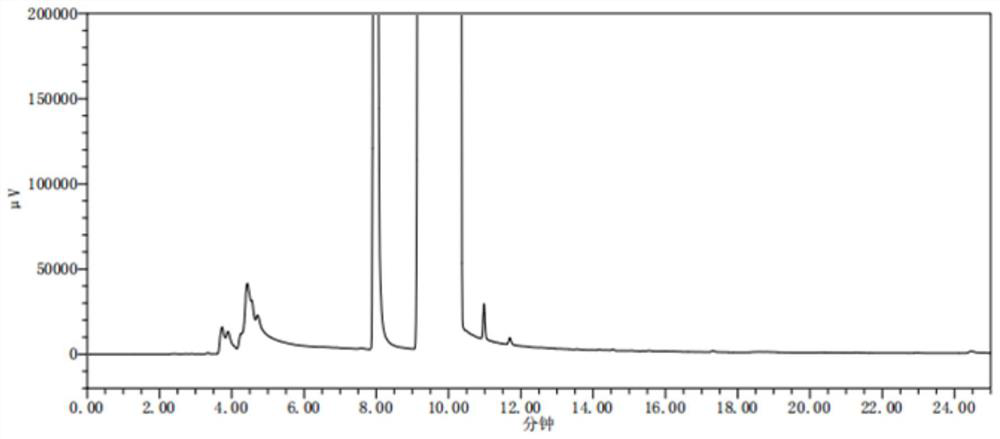

[0049] (1) Chromatographic conditions:

[0050] Instrument: gas chromatograph (Shimadzu GC-2014C), detector is hydrogen flame ionization detector (FID);

[0051] Chromatographic column: CP-Volamine, 30m×0.32mm, 5.0μm or a capillary column with equivalent performance;

[0052] Column temperature: the initial temperature is 100°C, maintained for 3 minutes, and raised to 220°C at a rate of 10°C per minute, maintained for 10 minutes;

[0053] The inlet temperature is 230°C; the detector temperature is 250°C;

[0054] Column flow rate is 1.0mL / min

[0055] Blank solvent: dimethylsulfoxide.

[0056] (2) Solution preparation: See Table 1 for the solution preparation process.

[0057] Table 1 Triethylamine and N, N-diethylaniline solution preparation process

[0058]

[0059] The specific operation is as follows:

[0060] N,N-diethylaniline stock solution: Take 50mg of N,N-diethylaniline, put it in a 100mL measuring bottle, add dimethyl sulfoxide to dissolve and dilute to the...

Embodiment 2

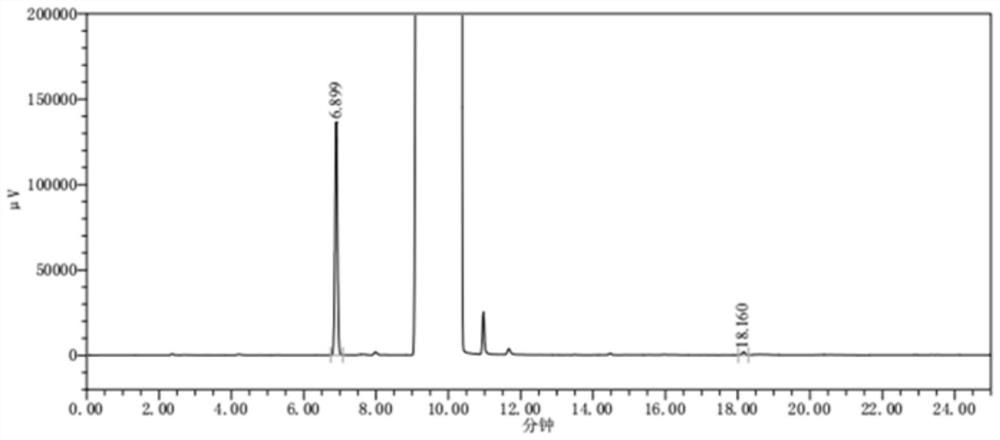

[0092] Verification Example 2: Linearity and Range

[0093] (1) Test process:

[0094] The preparation process of the linear solution is shown in Table 7 (preparation process of the linear solution of triethylamine and N,N-diethylaniline). Precisely measure 1 μL of each linear solution, inject them into the gas chromatograph respectively, and record the chromatogram. 30% linear solution is limit of quantitation, as the starting point of linearity, with the concentration of each solution as abscissa, with each solvent peak area as ordinate to carry out linear regression (results see Figure 7 and Figure 8 ).

[0095] Table 7 Triethylamine and N, N-diethylaniline linear solution preparation process

[0096] linear solution Triethylamine concentration (μg / mL) N, N-diethylaniline concentration (μg / mL) prepare 30% 150.00 1.50 Linear stock solution 3mL→20mL 40% 200.00 2.00 Linear stock solution 2mL→10mL 60% 300.00 3.00 Linear stock solutio...

Embodiment 3

[0112] Validation Example 3: Limits of Detection and Limits of Quantitation

[0113] (1) Test process:

[0114] Accurately measure the linear solution (limit 30%) under "Verification Example 2: Linearity and Range", the signal-to-noise ratio (S / N) is greater than 10:1, which can be used as the limit of quantification. Dilute the limit of quantitation, according to the signal-to-noise ratio (S / N) greater than 3:1, can be used as the detection limit. The quantitative limit was injected 6 times continuously, the peak area was recorded, and the average value and RSD value were calculated.

[0115] (2) Results and conclusions:

[0116] Table 10 triethylamine, N, N-diethylaniline quantitative limit and detection limit results

[0117]

[0118] Table 11 Triethylamine, N, N-diethylaniline quantitative limit system precision results

[0119] Element 1 2 3 4 5 6 average RSD(%) Triethylamine 203956 204855 199872 200868 198898 198591 201173 1.32 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com