Total phosphate electrode material and preparation method thereof

A technology of electrode material and full phosphate, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve problems such as poor stability, poor rate performance of bimetallic nickel-cobalt phosphide, and unsatisfactory cycle performance. High energy density, beneficial to flow and conduction, and enhanced electrochemical reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

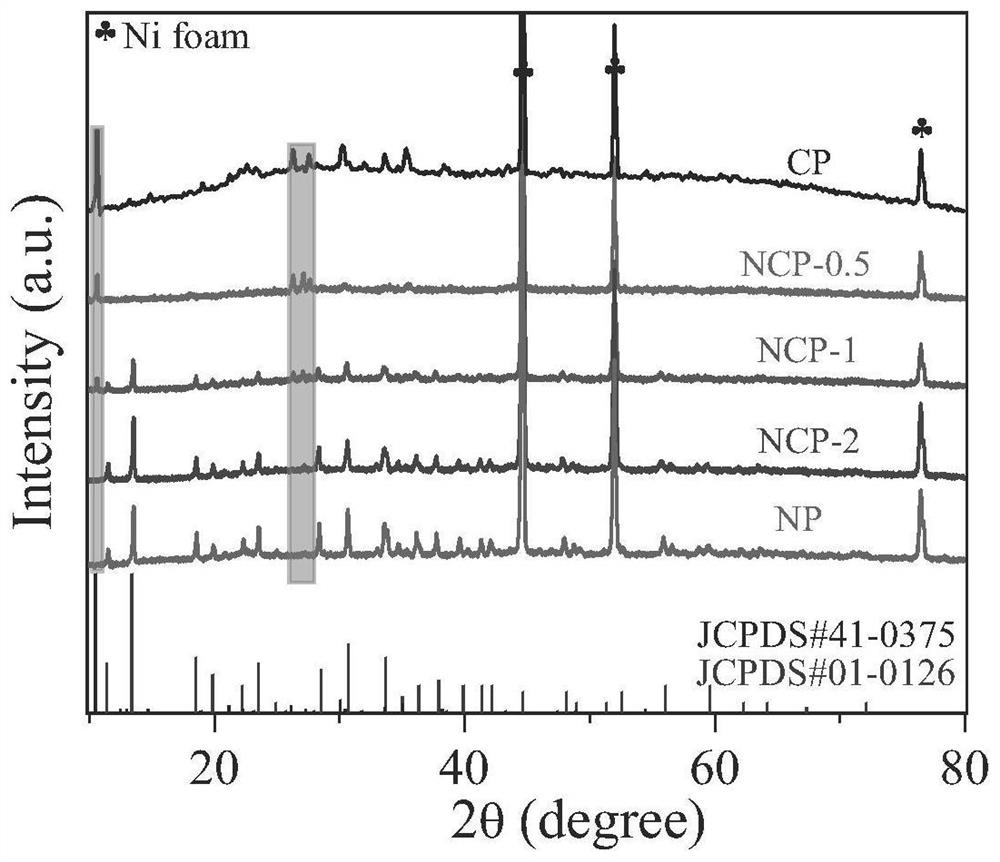

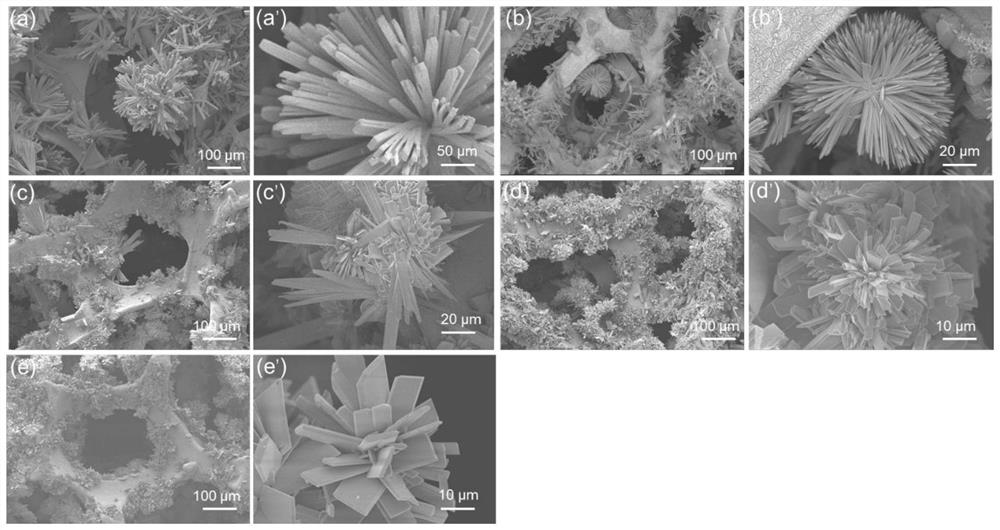

[0047] The embodiment of the present invention provides a kind of preparation method of all-phosphate electrode material, comprises the following steps:

[0048] S1. Growing sheet-shaped nickel-cobalt phosphate on the surface of the substrate by a hydrothermal method to obtain the substrate loaded with the sheet-shaped nickel-cobalt phosphate;

[0049] S2. Using the substrate supporting the flaky nickel-cobalt phosphate as a working electrode, deposit nickel-cobalt hydrogen phosphate on the surface of the flaky nickel-cobalt phosphate by electrodeposition to obtain a full phosphate electrode material.

[0050] The sheet structure of single nickel cobalt phosphate is unstable and easy to collapse. Based on this, the present invention selects two different nickel-cobalt phosphate materials as battery-type capacitor materials for compounding, using sheet-shaped nickel-cobalt phosphate as the basis to provide a large number of deposition sites, and then compounding on it with high...

Embodiment 1

[0072] The preparation of the substrate of embodiment 1 load sheet-shaped nickel-cobalt phosphate

[0073] The sheet-shaped nickel-cobalt phosphate is grown on the surface of the substrate by a hydrothermal method to obtain a substrate loaded with sheet-shaped nickel-cobalt phosphate; the specific operations include:

[0074] S11, using water as a solvent, preparing a mixed solution containing nickel chloride and cobalt chloride, adding dipotassium hydrogen phosphate solution dropwise thereto, and then mixing and stirring for 30 minutes to make it evenly mixed to obtain a reaction solution, in which nickel ions and The total molar concentration of cobalt ions is 1.8mM, and the molar concentration of hydrogen phosphate ions is 1.2mM;

[0075] S12. Pour 10mL of the reaction solution into a 25mL reactor, add nickel foam as a substrate, and conduct a hydrothermal reaction at 150°C for 12 hours. After the reaction is completed, the product is washed and dried to obtain a substrate ...

Embodiment 2

[0082] The preparation of embodiment 2 full phosphate electrode material

[0083] A preparation method for an all-phosphate electrode material, comprising the following steps:

[0084] S1. Growth of flaky nickel-cobalt phosphate on the surface of the substrate by hydrothermal method to obtain a substrate loaded with flaky nickel-cobalt phosphate, the specific operation is the same as that of Example 1;

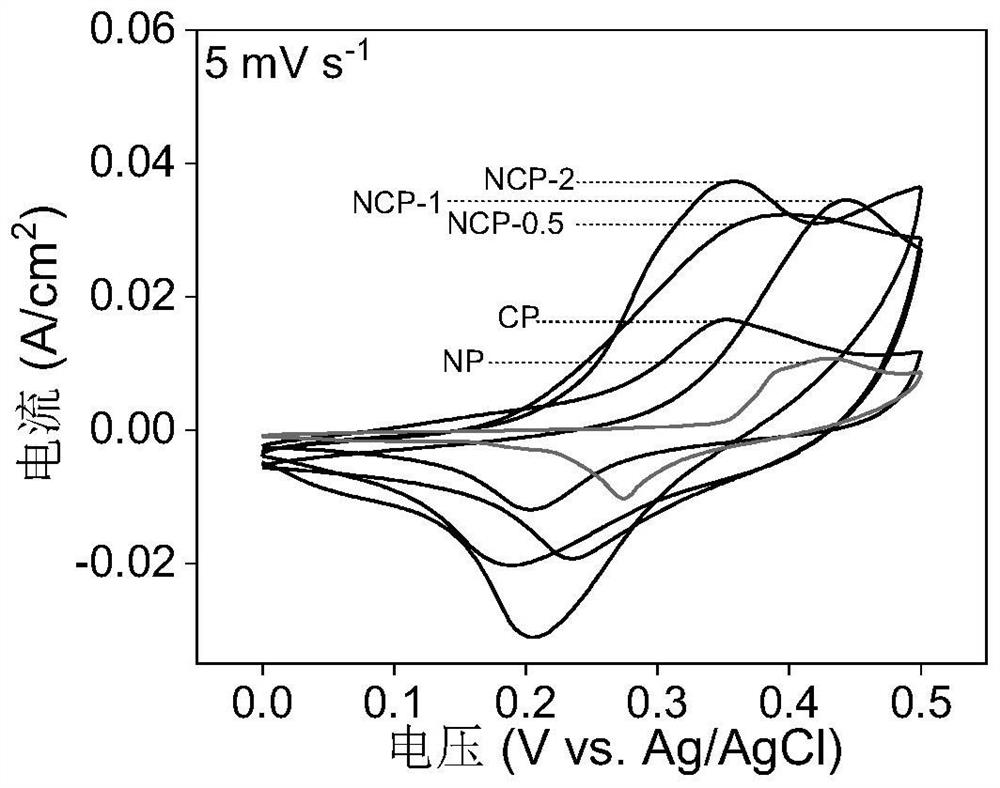

[0085] In the present embodiment, the molecular formula of nickel-cobalt phosphate is: Ni 2 Co(PO 4 ) 2 ;

[0086] S2. A three-electrode system is constructed with the substrate loaded with sheet-like nickel-cobalt phosphate as the working electrode, Pt as the counter electrode, and Ag / AgCl as the reference electrode. The three-electrode system is placed in the electrolyte and scanned by cyclic voltammetry for 6 Circle, the scanning voltage is -1.2 to 0.2V, and the scanning rate is 5mv / s, nickel-cobalt hydrogen phosphate is electrodeposited on the surface of nickel-cobalt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com