Olefin hydration reaction system and olefin hydration method

A technology for hydration of olefins and olefins, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical/physical chemical fixed reactors, etc., can solve poor mixing and dispersion effects, low mass transfer efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

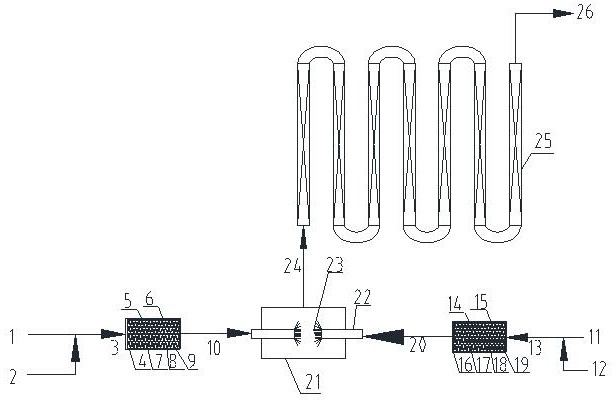

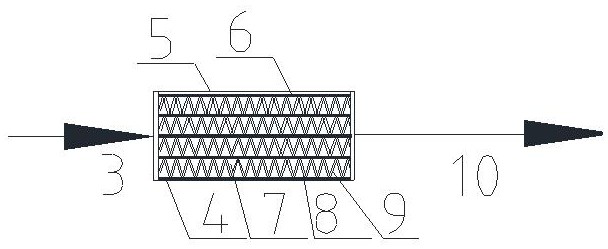

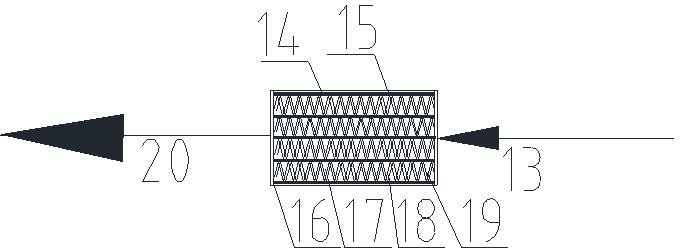

[0039] The mass ratio of olefin and water is introduced into the first mixing device with a ratio of 4:1 to form the first mixed material, and the mass ratio of olefin and water is introduced into the second mixed device with a ratio of 1:9 to form the second mixed material; the first The mass ratio of the mixed material to the second mixed material is 1:1. The first mixed material and the second mixed material are mixed through pipelines and then introduced into a tubular reactor for olefin hydration reaction. The bottom of the reactor is fed, and it is divided into four sections of reactors. The straight pipe section of each section is 2 meters long and four sections The reactors are connected in sequence. The straight pipe section of the reactor is 8 meters long in total, and the straight pipe section in the reactor is filled with olefin hydration catalyst.

[0040] In the first mixing equipment, the sheet in the microchannel mixing assembly is made of stainless steel, the ...

Embodiment 2

[0043] The water-alkene mass ratio is introduced into the first mixing device with a ratio of 5:1 to form the first mixed material, and the water-alkene mass ratio is introduced into the second mixed material with a ratio of 1:11 to form the second mixed material, the first mixed material and the second mixed material The mass ratio of the secondary mixture materials is 1:1. The two streams of materials are introduced into both ends of the homogenizer, and after being diverted by the guide tubes at both ends and ejected from the nozzle, they collide with each other, and the droplets in the two streams of materials permeate and diffuse each other to form a uniform mixture and introduce it into the tubular reactor. Olefin hydration reaction, feed at the bottom, is divided into three sections of reactors, each section of straight pipe is 3 meters long, and the three sections of reactors are connected in sequence, with a total length of 9 meters, and the straight pipes in the react...

Embodiment 3

[0047] Water ene mass ratio is introduced into the first mixing device with the ratio of 6:1 to form the first mixed material, and water ene mass ratio is introduced into the second mixed device with the ratio of 1:13 to form the second mixed material; the first mixed material and the second mixed material The mass ratio of the secondary mixture materials is 1:1. The two streams of materials are introduced into both ends of the homogenizer, and after being diverted by the guide tubes at both ends and ejected from the nozzle, they collide with each other, and the droplets in the two streams of materials permeate and diffuse each other to form a uniform mixture and introduce it into the tubular reactor. Olefin hydration reaction, feed at the bottom, is divided into five sections of reactors, each section of straight pipe is 2 meters long, and the five sections of reactors are connected in sequence, with a total length of 10 meters, and the straight pipes in the reactor are all fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com