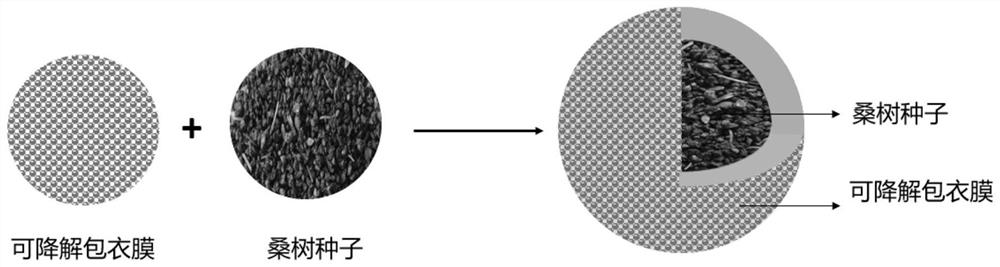

Degradable mulberry seed coating film agent as well as preparation method and use method thereof

A technology for coating film and seeds, applied in the direction of seed coating/seed dressing, application, nitrogen fertilizer, etc., can solve the problems of pollution of the ocean, the entry of pesticides into rivers, pollution of the atmosphere, etc. The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

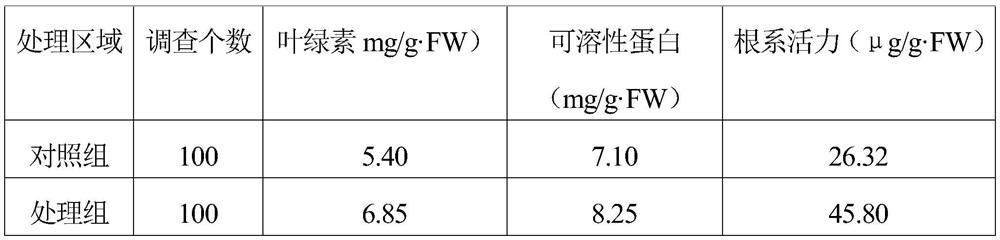

Examples

Embodiment 1

[0030] 1) Add 6 parts of 20% nitric acid solution to 200 parts of deionized water, add 0.5 part of chitosan to it while stirring, then place it at a constant temperature of 65°C and stir until it is completely dissolved, and let it stand for a while to make the shell The bubbles in the polysan disappear, and the chitosan solution A is obtained, which is set aside;

[0031] 2) Dissolving 30 parts of humic acid in a strong alkali solution with a pH of 13 to obtain a humate solution B with a mass fraction of 5%, and set aside;

[0032] 3) Dissolve 5 parts of urea into 45 parts of deionized water and stir evenly to obtain urea solution C, which is set aside;

[0033] 4) Stir chitosan solution A, humic acid solution B and urea solution C at a constant temperature of 45°C for 1.5 hours to mix them evenly to obtain a mixed solution;

[0034] 5) Add 8 parts of polyvinyl alcohol and 8 parts of tri-n-butyl citrate into the container, stir evenly, put them into the reaction kettle, and ...

Embodiment 2

[0039] 1) Add 3 parts of 20% nitric acid solution to 100 parts of deionized water, add 0.3 parts of chitosan to it while stirring, then place it at a constant temperature of 60°C and stir until it is completely dissolved, and let it stand for a while to make the shell The bubbles in the polysan disappear, and the chitosan solution A is obtained, which is set aside;

[0040] 2) Dissolving 24 parts of humic acid in a strong alkali solution with a pH of 11 to obtain a humate solution B with a mass fraction of 3%, and set aside;

[0041] 3) Dissolve 1 part of urea into 10 parts of deionized water, and stir evenly to obtain urea solution C, which is set aside;

[0042] 4) Stir chitosan solution A, humic acid solution B and urea solution C at a constant temperature of 35°C for 1 hour to mix them evenly to obtain a mixed solution;

[0043] 5) Add 4 parts of propylene glycol phenyl ether and 4 parts of tributyl citrate into the container, stir evenly, put them into the reaction kettl...

Embodiment 3

[0048] 1) Add 6 parts of 20% nitric acid solution to 150 parts of deionized water, add 0.3 parts of chitosan to it under stirring conditions, then place it at a constant temperature of 60°C and stir until it is completely dissolved, and let it stand for a period of time to make the shell The bubbles in the polysan disappear, and the chitosan solution A is obtained, which is set aside;

[0049] 2) Dissolving 25 parts of humic acid in a strong alkali solution with a pH of 12 to obtain a humate solution B with a mass fraction of 4%, set aside;

[0050] 3) Dissolve 2 parts of urea into 20 parts of deionized water, and stir evenly to obtain urea solution C, which is set aside;

[0051] 4) Stir chitosan solution A, humic acid solution B and urea solution C at a constant temperature of 35°C for 1 hour to mix them evenly to obtain a mixed solution;

[0052] 5) Add 5 parts of AH-12 and 5 parts of polyethylene glycol into the container, stir evenly, put it into the reaction kettle, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com