Method for immobilizing microorganism high-yield hyaluronic acid by using 3D printing technology

A 3D printing and hyaluronic acid technology, applied in the field of hyaluronic acid preparation, can solve the problems of high operating cost, low reusability, and complicated purification steps, and achieve simplified purification steps, high antioxidant activity, and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

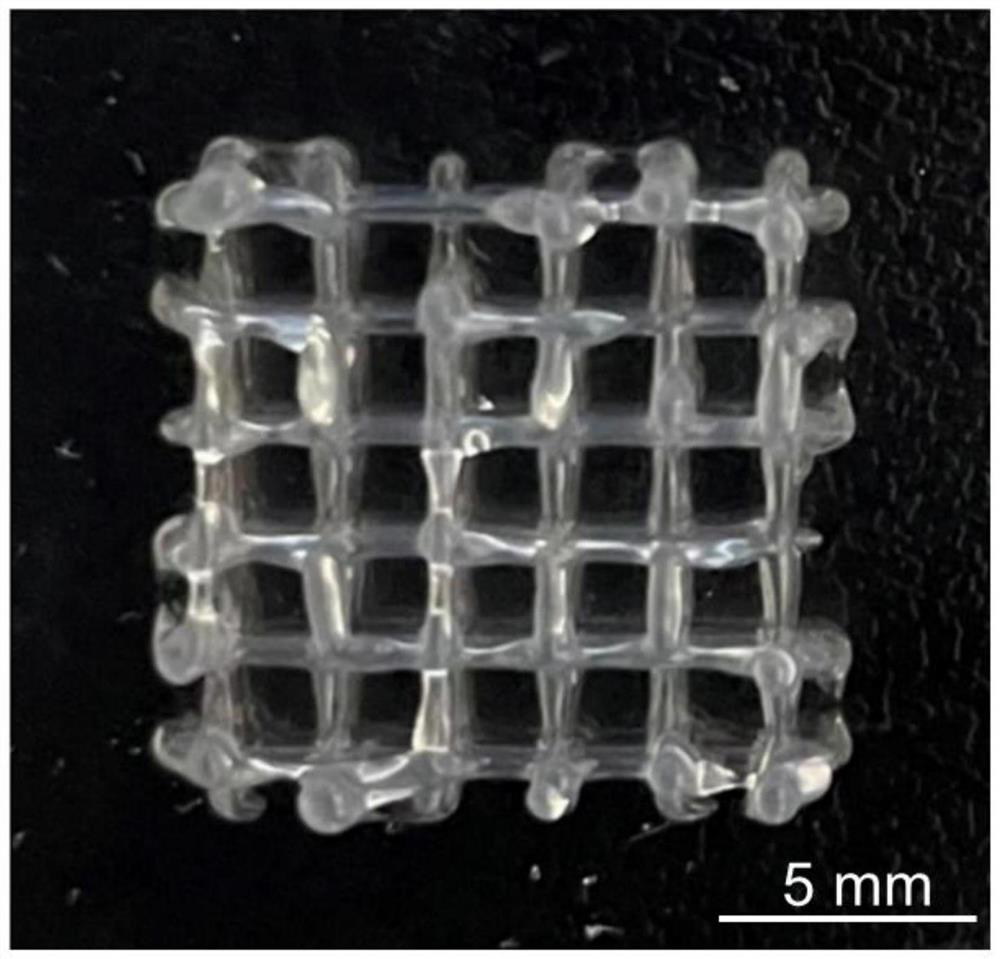

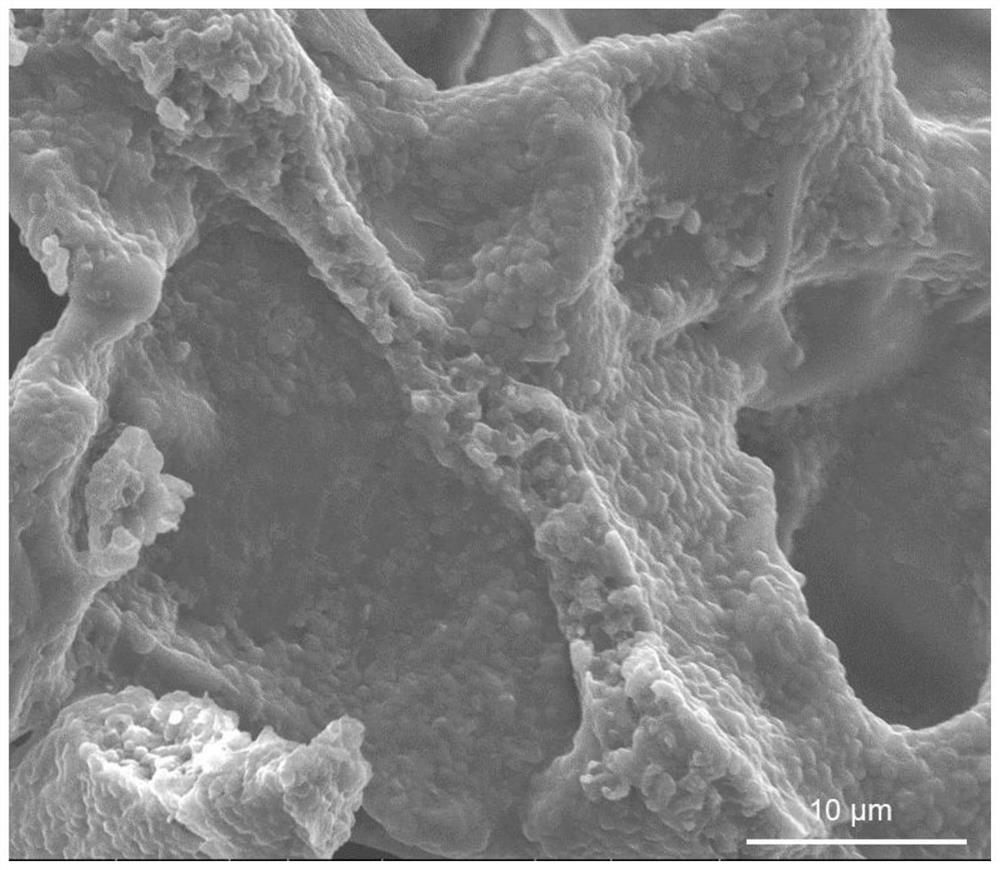

[0039] Example 1 Preparation method of high-yield hyaluronic acid by immobilized microorganism using 3D printing technology

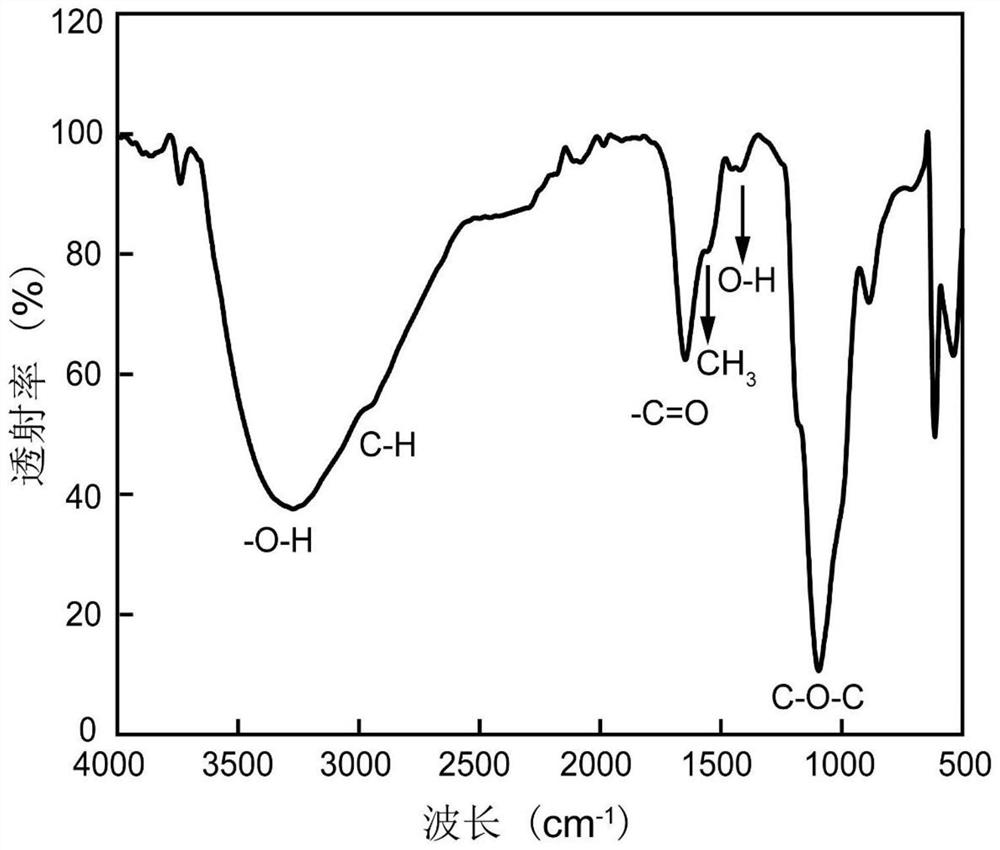

[0040] (1) A-type pigskin gelatin was dissolved in phosphate buffer (pH 7.4) at 50℃ to prepare 10% gelatin solution, and then methacrylic anhydride (0.6g of methacrylic anhydride per 1g of gelatin) was dripped into the gelatin solution at 50℃, stirred and reacted for 3h. After 3 hours of reaction, the solution was centrifuged at 3500g for 3min, the supernatant was collected and heated at four times the volume. The diluted gelatin solution was dialyzed with deionized water (MWCO, 8000-14000 DA) at 40℃ for 7 days, and the product was collected by freeze-drying to obtain the modified GelMA.

[0041](2) Weigh 0.25g modified GelMA and 0.25g gel (type A pigskin gelatin) in 4.5mL deionized water, stir and mix the obtained mixture at a constant speed of 500rpm at 37℃, and after it is completely dissolved, mix the mixture with LAP (the mass-volume ratio to the deion...

Embodiment 2

[0046] Example 2 Preparation method of high-yield hyaluronic acid by immobilized microorganism using 3D printing technology

[0047] (1) A-type pigskin gelatin was dissolved in phosphate buffer (pH 7.4) at 50℃ to prepare 10% gelatin solution, and then methacrylic anhydride (0.6g of methacrylic anhydride per 1g of gelatin) was dripped into the gelatin solution at 50℃, stirred and reacted for 3h. After 3 hours of reaction, the solution was centrifuged at 3500g for 3min, the supernatant was collected and heated at four times the volume. The diluted gelatin solution was dialyzed with deionized water (MWCO, 8000-14000 DA) at 40℃ for 7 days, and the product was collected by freeze-drying to obtain the modified GelMA.

[0048] (2) Weigh 0.25g modified GelMA and 0.25g gel (type A pigskin gelatin) in 4.5mL deionized water, stir and mix the obtained mixture at a constant speed of 500rpm at 37℃, and after it is completely dissolved, mix the mixture with LAP (the mass-volume ratio to the deio...

Embodiment 3

[0052] Example 3 Preparation method of high-yield hyaluronic acid by immobilized microorganism using 3D printing technology

[0053] (1) A-type pigskin gelatin was dissolved in phosphate buffer (pH 7.4) at 50℃ to prepare 10% gelatin solution, and then methacrylic anhydride (0.6g of methacrylic anhydride per 1g of gelatin) was dripped into the gelatin solution at 50℃, stirred and reacted for 3h. After 3 hours of reaction, the solution was centrifuged at 3500g for 3min, the supernatant was collected and heated at four times the volume. The diluted gelatin solution was dialyzed with deionized water (MWCO, 8000-14000 DA) at 40℃ for 7 days, and the product was collected by freeze-drying to obtain the modified GelMA.

[0054] (2) Weigh 0.25g modified GelMA and 0.25g gel (type A pigskin gelatin) in 4.5mL deionized water, stir and mix the obtained mixture at a constant speed of 500rpm at 37℃, and after it is completely dissolved, mix the mixture with LAP (the mass-volume ratio to the deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com