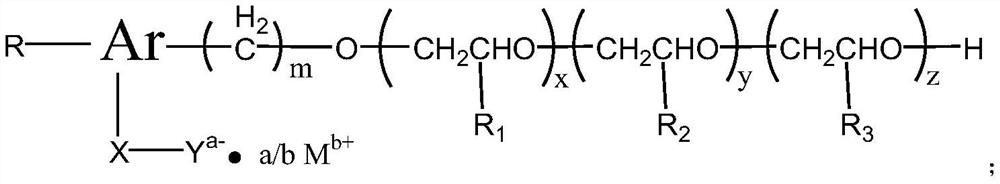

Polyether anionic surfactant and method for improving oil and gas recovery ratio

A surfactant and anionic technology, applied in the field of polyether anionic surfactants, can solve problems such as poor sweep efficiency, high viscosity of crude oil, and poor fluidity of crude oil, and achieve strong salt resistance, high hydrothermal stability, and salt resistance The effect of ability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

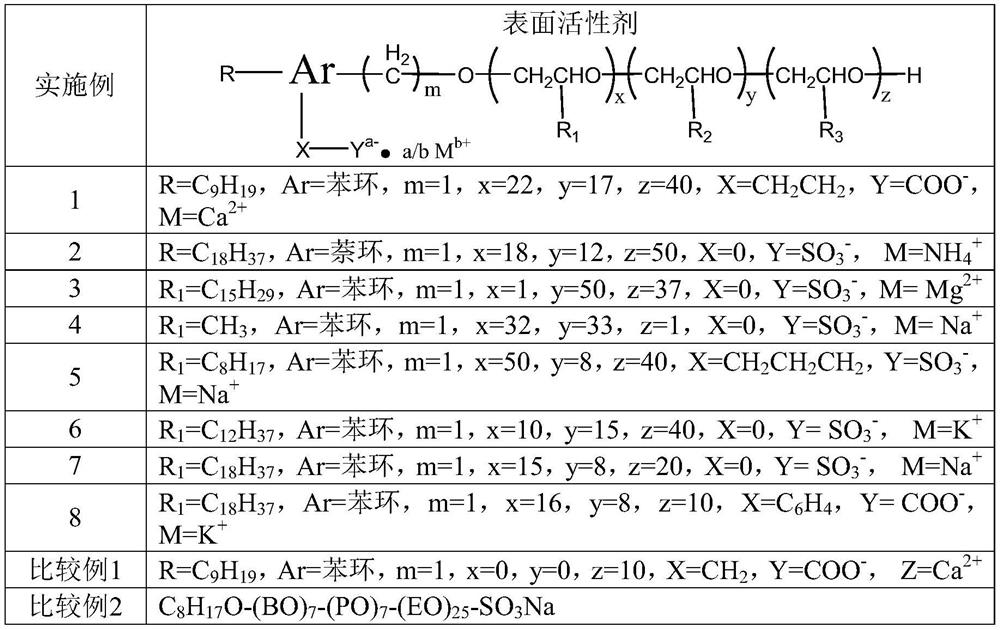

Embodiment 1

[0031] Synthesis of Octadecyl Naphthalene Methanol Polyether Ammonium Sulfonate Anionic Nonionic Surfactant:

[0032] Add a certain amount of octadecylnaphthalene methanol and 0.5% KOH by mass and 30ppm phosphazene catalyst in the polymerization reactor, heat the system temperature to 80-90°C under stirring, open the vacuum system, dehydrate for 1 hour, and then use Nitrogen is purged 3 to 4 times to remove the air in the system, and then the reaction temperature is raised to 200°C, and then a metered amount of butylene oxide is slowly introduced to control the reaction pressure <2.0MPa to carry out the etherification reaction. After the reaction of this step is completed, the temperature is lowered to 180°C, and the calculated amount of propylene oxide is continued to be introduced slowly. Until the end of the reaction (the reaction pressure remains constant), the system is purged with nitrogen to remove unreacted ethylene oxide to obtain the alkylaryl polyether nonionic surf...

Embodiment 2

[0048] Synthesis of Nonylbenzyl Alcohol Polyether Carboxylate Calcium Anion Nonionic Surfactant:

[0049] Add a certain amount of 4-nonyl 2-hydroxymethylphenylpropionic acid and 1% KOH based on its mass as a catalyst in the polymerization reactor, heat the system temperature to 80-90°C while stirring, turn on the vacuum system, and dehydrate for 1 hour , and then purged with nitrogen for 3 to 4 times to remove the air in the system, then raise the reaction temperature to 200°C and slowly feed in the measured amount of butylene oxide, and control the reaction pressure <2.0MPa to carry out the etherification reaction. After the reaction of this step is completed, the temperature is lowered to 180°C, and the calculated amount of propylene oxide is continued to be introduced slowly. Until the reaction is finished (the reaction pressure remains constant), the system is purged with nitrogen to remove unreacted ethylene oxide to obtain 4-nonyl-2-hydroxymethyl polyether potassium phen...

Embodiment 3

[0059] Synthesis of Pentadecylbenzyl Alcohol Polyether Sulfonate Magnesium Anionic Nonionic Surfactant:

[0060] Add pentadecylbenzyl alcohol, 2.0% KOH by mass and 30ppm phosphazene catalyst in the polymerization reactor, heat the system temperature to 80-90°C under stirring, open the vacuum system, dehydrate for 1 hour, and then blow it with nitrogen 3 to 4 times to remove the air in the system, then raise the reaction temperature to 180°C and then slowly feed in the measured amount of butylene oxide, and control the reaction pressure <0.60MPa to carry out the etherification reaction. After the reaction of this step is finished, continue to slowly feed the calculated amount of propylene oxide. After the reaction is over, add the calculated amount of ethylene oxide again, cool down to 150° C., and carry out the etherification reaction again until the end of the reaction (reaction pressure constant), with nitrogen purging system, remove unreacted oxirane, obtain pentadecylbenzy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com