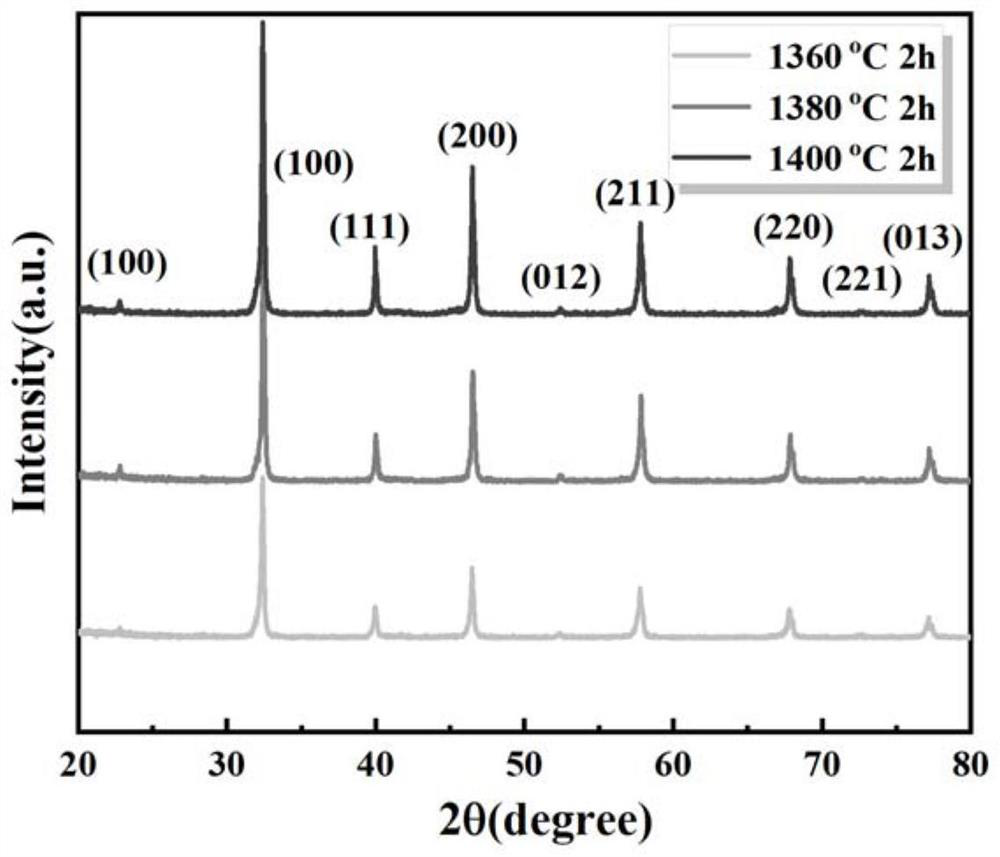

Preparation method of strontium titanate ceramic with high dielectric constant and frequency stability

A frequency stability, high dielectric constant technology, applied in the field of nanomaterial preparation, can solve the problems of increasing dielectric loss, vacancy defect space charge, relaxor ferroelectricity, etc., to achieve reduced dielectric loss, uniform sample size, The effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

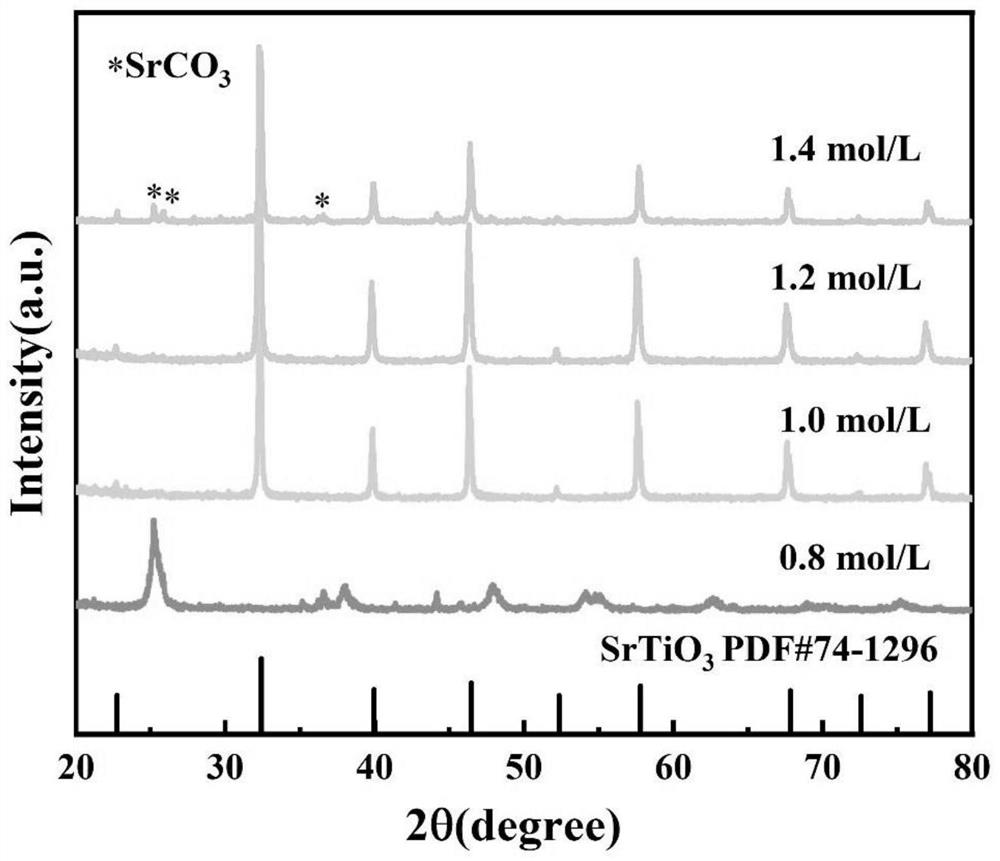

Embodiment 1

[0027] (1), weigh 1.926g Sr(NO 3 ) 2 Add 39mL deionized water and stir for 18min to obtain solution A;

[0028] (2), 1mL TiCl 4 Slowly drop into solution A, stir well until the solution is completely transparent, and obtain solution B;

[0029] (3), adding 1.248 g of NaOH with a concentration of 8.8 mol / L into solution B, stirring for 1 h, to obtain milky white suspension C;

[0030] (4) Transfer suspension C to a 58mL reaction kettle, and react under high pressure at 188°C for 12h to obtain product D;

[0031] (5) Pour the product D into a centrifuge tube, centrifuge and wash it with deionized water for more than 4 times in a centrifuge until the pH is neutral, and dry it in a vacuum oven at 88°C for 24 hours. Due to insufficient reaction driving force, and Not enough to generate SrTiO 3 Nano powder.

Embodiment 2

[0033] (1), weigh 1.926g Sr(NO 3 ) 2 Add 39mL deionized water and stir for 18min to obtain solution A;

[0034] (2), 1mL TiCl 4 Slowly drop into solution A, stir well until the solution is completely transparent, and obtain solution B;

[0035] (3), adding 1.568 g of NaOH with a concentration of 1.8 mol / L into solution B, stirring for 1 h, to obtain milky white suspension C;

[0036] (4) Transfer suspension C to a 58mL reaction kettle, and react under high pressure at 188°C for 12h to obtain product D;

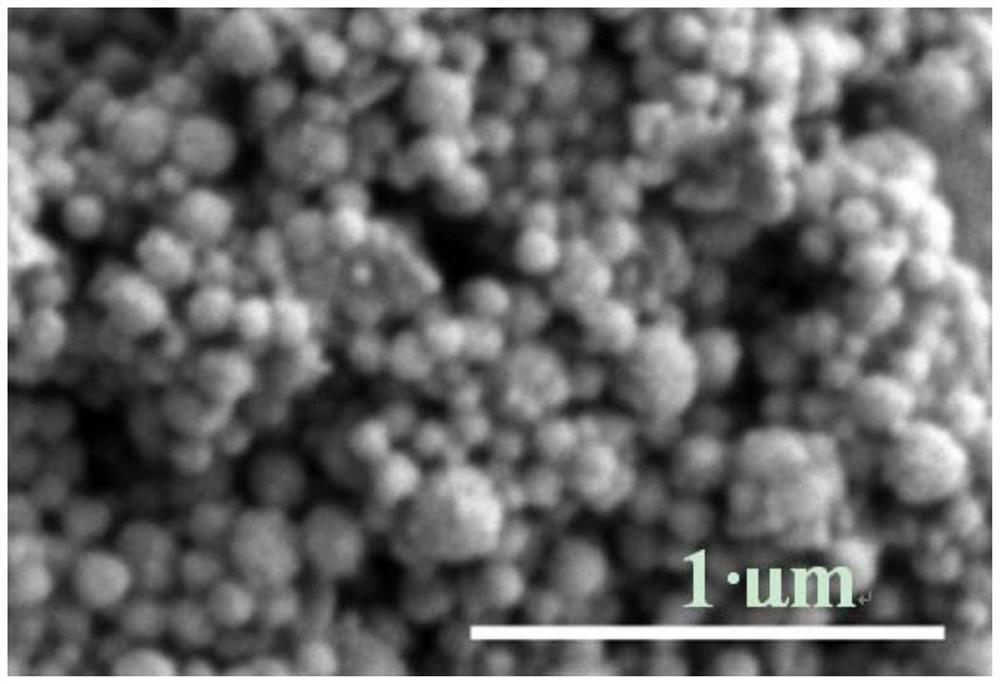

[0037] (5) Pour the product D into a centrifuge tube, centrifuge and wash it with deionized water for more than 4 times in a centrifuge until the pH is neutral, and dry it in a vacuum oven at 88°C for 24 hours to obtain pure single titanic acid Strontium nanopowder.

Embodiment 3

[0039] (1), weigh 1.926g Sr(NO 3 ) 2 Add 39mL deionized water and stir for 18min to obtain solution A;

[0040] (2), 1mL TiCl 4 Slowly drop into solution A, stir well until the solution is completely transparent, and obtain solution B;

[0041] (3), adding 1.872g of NaOH with a concentration of 1.2mol / L into solution B, stirring for 1h, to obtain milky white suspension C;

[0042] (4) Transfer suspension C to a 58mL reaction kettle, and react under high pressure at 188°C for 12h to obtain product D;

[0043] (5) Pour the product D into a centrifuge tube, centrifuge and wash it with deionized water for more than 4 times in a centrifuge until the pH is neutral, and dry it in a vacuum oven at 88°C for 24 hours to obtain pure single titanic acid Strontium nanopowder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com