Special organic fertilizer production line for rice and process for producing organic fertilizer

A production process and technology for organic fertilizers, which are applied to the production line of organic fertilizers for rice and the technical field of producing organic fertilizers, can solve the problems of time-consuming and energy-consuming, uneven addition positions, contact surfaces between fermented products and air, and insufficient contact time, etc. Achieving the effect of sufficient oxygenation, labor-saving processing, and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

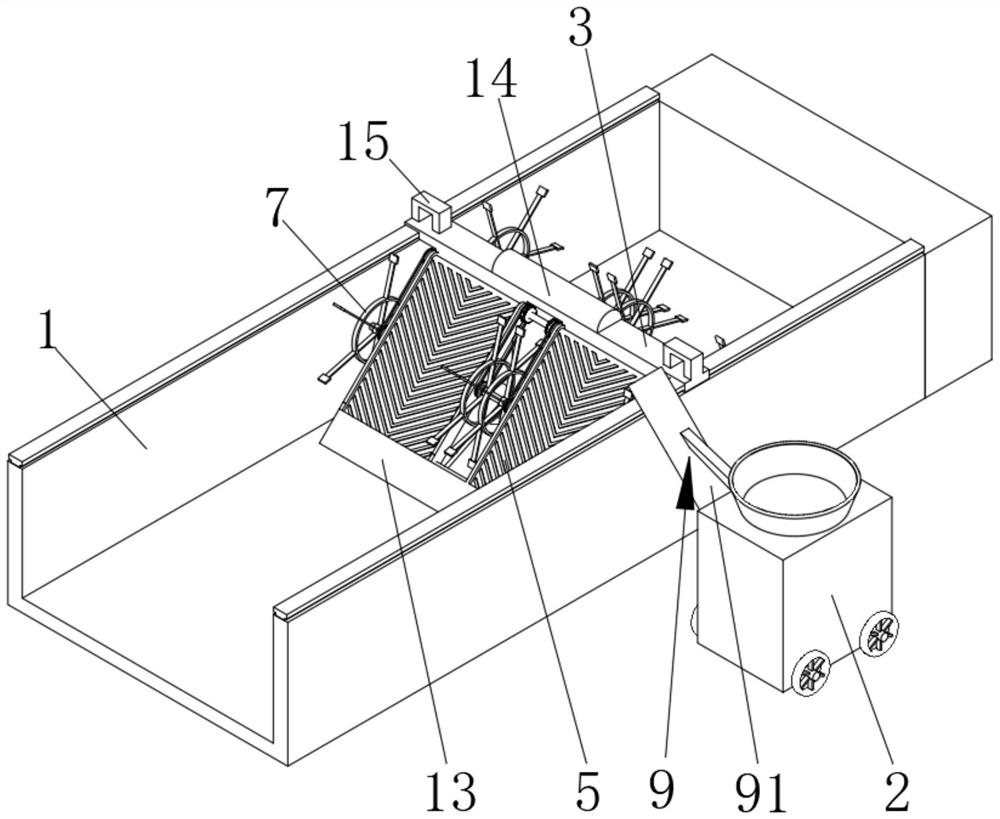

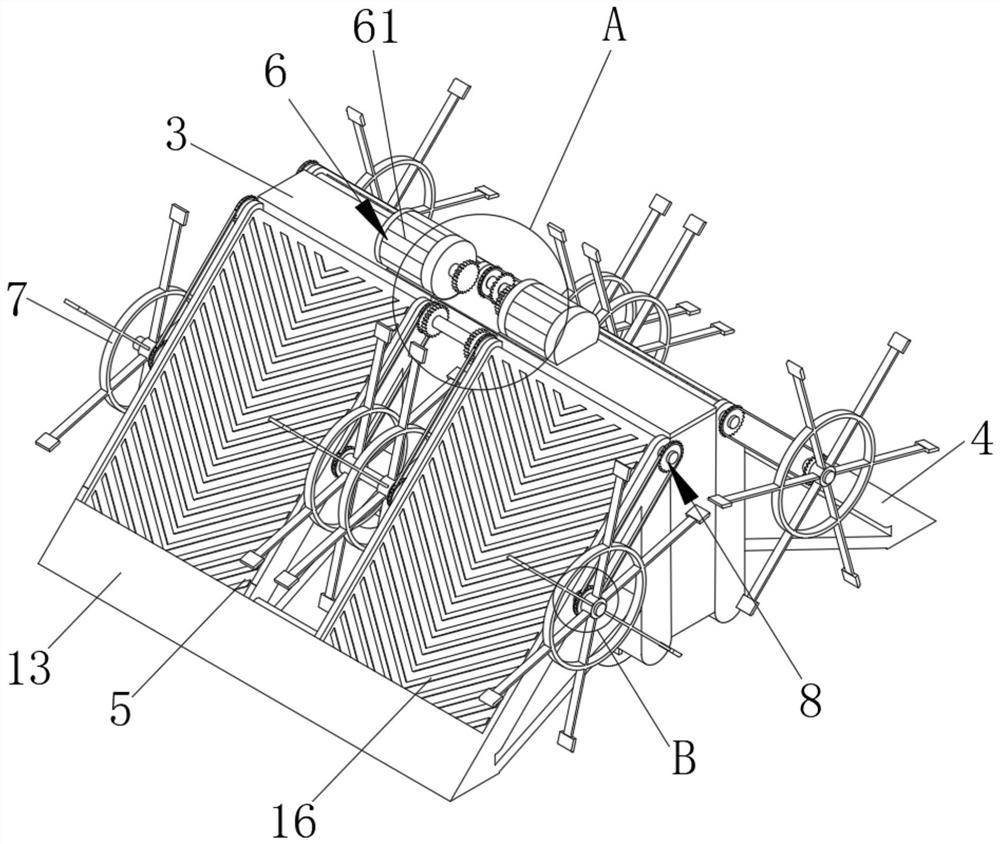

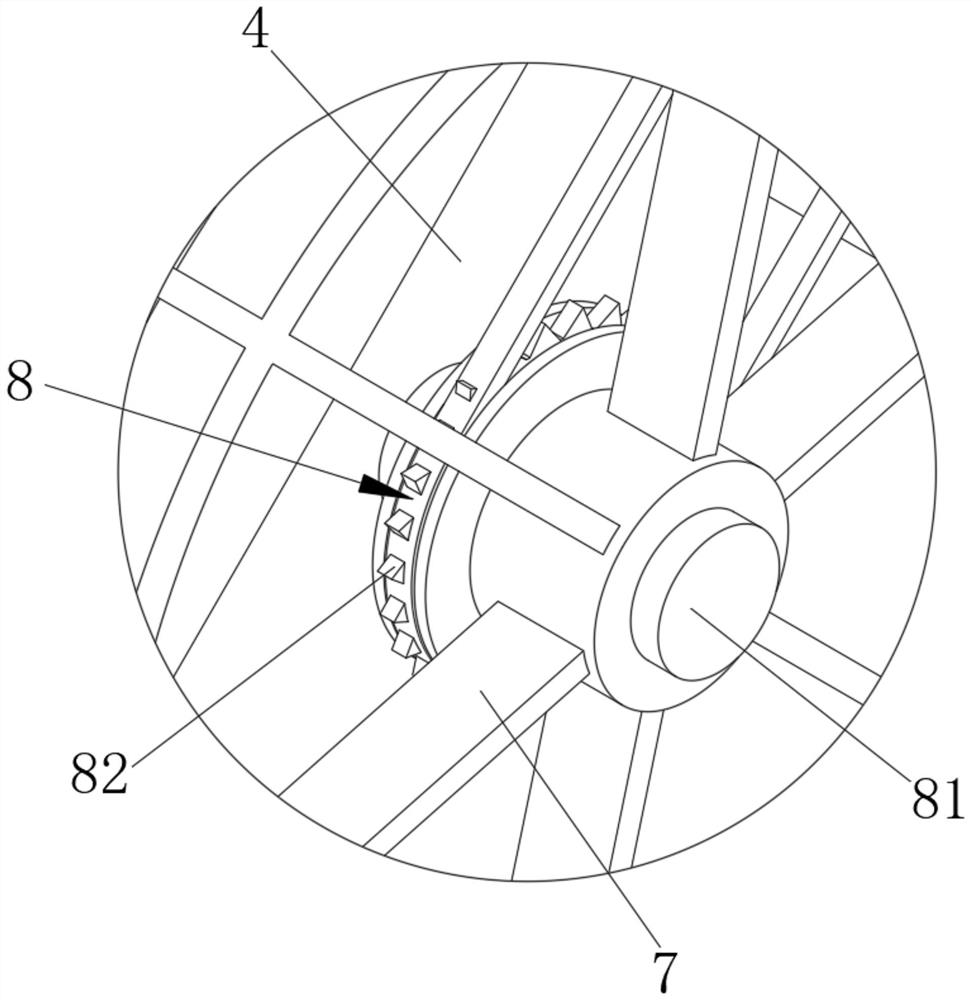

[0035] Figure 1-6The production process of the rice-specific organic fertilizer according to an embodiment of the present invention is at least composed of the following processes: dropping feces into the fermentation tank, using herbivorous cow dung as the main choice of feces, and transporting the crushed straw fragments to In the inner cavity of the fermentation tank, the straw fragments and feces are then mixed evenly by a turning machine. During the process of putting in straw fragments, the process of turning over and feeding is carried out synchronously, so as to achieve full mixing of the feces and straw fragments, and then to the Spray the fermentation solution inside the fermentation tank. The fermentation solution uses carbohydrates containing microorganisms. The main components of carbohydrates are ethanol, acetone-butanol, butanol-isopropanol, acetone-ethanol, 2,3-butanediol and glycerin for fermentation. During the period, the internal temperature of the ferment...

Embodiment 2

[0041] Figure 1-6 The production process of the special organic fertilizer for rice according to an embodiment of the present invention is at least composed of the following process: put feces into the fermentation tank body 1, the feces are selected from dairy cow dung mainly grazing, and the crushed straw fragments It is transported to the inner cavity of the fermentation tank body 1, and then the straw fragments and feces are mixed evenly by a turning machine. During the process of putting straw fragments, the process of turning over and feeding is carried out synchronously, so as to achieve full mixing of feces and straw fragments. Afterwards, the fermentation solution is sprayed into the fermentation tank body 1. The fermentation solution adopts carbohydrates containing microorganisms. The main components of carbohydrates are ethanol, acetone-butanol, butanol-isopropanol, acetone-ethanol, 2,3-butanol Glycol and glycerin are fermented. During the fermentation period, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com