Aqueous positive electrode polymer, preparation method thereof and small molecule flow battery system

A technology for flow batteries and polymers, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve the problems of restricting the large-scale application of flow batteries, cross-contamination of porous membranes, and large pore size of porous membranes, and achieve suppression of concentration differences. Polarization phenomenon, meet the needs of large-scale energy storage, the effect of fast charge and discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

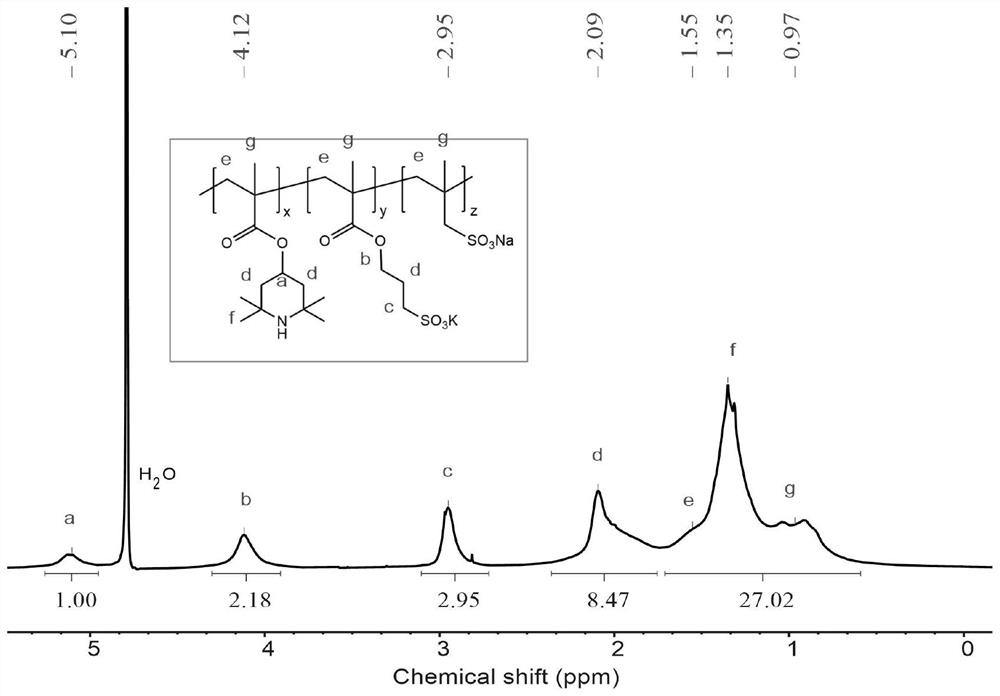

[0049] The present invention also provides a method for preparing the above-mentioned water-based positive electrode polymer, comprising the following steps: Ester (TEMPMA), monomer 3-sulfonic acid propyl methacrylate potassium salt (SMPS) and monomer 2-methyl-2-propene-1-sulfonic acid sodium (SMAS) as raw materials, adding initiator, through free The method for preparing the water-based positive electrode polymer by base polymerization, the chemical reaction formula is as shown in formula (1):

[0050]

[0051] Specifically, the method for preparing the water-based positive electrode polymer includes the following steps: S11. In a container, sequentially add TEMPMA, SMPS, SMAS and dilute hydrochloric acid. After all the solids are dissolved, the initiator is added, and the 2 Stir and heat to remove oxygen in the environment, react for 18-24h; after the reaction, cool to room temperature; add NaOH dropwise to adjust to alkalinity, and then use a dialysis bag with a molecul...

Embodiment 1

[0081] Preparation of an Aqueous Positive Electrode Polymer by Free Radical Polymerization

[0082] In a 250 mL flask with a branch tube, TEMPMA (5.633 g 25 mmol), SMPS (7.512 g 30.5 mmol), SMAS (1.58 g 10 mmol) and 100 mL 0.75 M dilute hydrochloric acid were added sequentially. After all the solids were dissolved, the initiator 4,4'-azobis(4-cyanovaleric acid) (ABCVA, 0.84 g) was added to obtain a suspension. Pass N 2 After 30min, heat to 80°C. The solution turned from cloudy to clear. Reaction 24h. After the reaction, cool to room temperature. NaOH (20wt%) was added dropwise until the pH was around 8. Carry out dialysis with a dialysis bag with a molecular weight cut-off of 1000, and freeze-dry the solution after the dialysis to obtain a white flocculent polymer;

[0083] Oxidation: Dissolve the polymer in 30 mL deionized water, add Na 2 WO 4 (0.6g), heated to 50°C, added dropwise H within 20h 2 o 2 (30wt%) 22mL, NaOH was added dropwise throughout the process to m...

Embodiment 2

[0085] In a 250 mL flask with a branch tube, TEMPMA (4.50 g 20 mmol), SMPS (4.92 g 20 mmol), SMAS (1.58 g 10 mmol) and 10 mL of 0.75 M dilute hydrochloric acid were sequentially added. After all the solids were dissolved, the initiator 4,4'-azobis(4-cyanovaleric acid) (ABCVA, 0.84 g) was added. Pass N 2 After 30min, heat to 65°C. The solution turned from cloudy to clear. Reaction 24h. After the reaction, cool to room temperature. NaOH (20wt%) was added dropwise until the pH was around 8. Carry out dialysis with a dialysis bag with a molecular weight cut-off of 1000, and freeze-dry the solution after the dialysis to obtain a white flocculent polymer;

[0086] Oxidation: Dissolve the polymer in 50 mL deionized water, add Na 2 WO 4 (0.6g), stirring at room temperature, adding H dropwise within 20h 2 o 2 (30wt%) 22mL, NaOH was added dropwise throughout the process to maintain the pH at 8-9. Reaction at room temperature for 24h. A dialysis bag with a molecular weight cut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com