PP-RCT special material with high beta crystal content, pipe and preparation methods of PP-RCT special material and pipe

A technology of PP-RCT and special materials, which is applied in the field of PP-RCT special materials and pipes and their preparation, can solve the problems of PP-RCT special materials with high β crystal content, etc., and achieve good toughness, excellent impact resistance and Effects of heat resistance and high β-crystal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1-4

[0050] 1. The PPR pipes with high β crystal content of each embodiment and each comparative example are prepared according to the following steps:

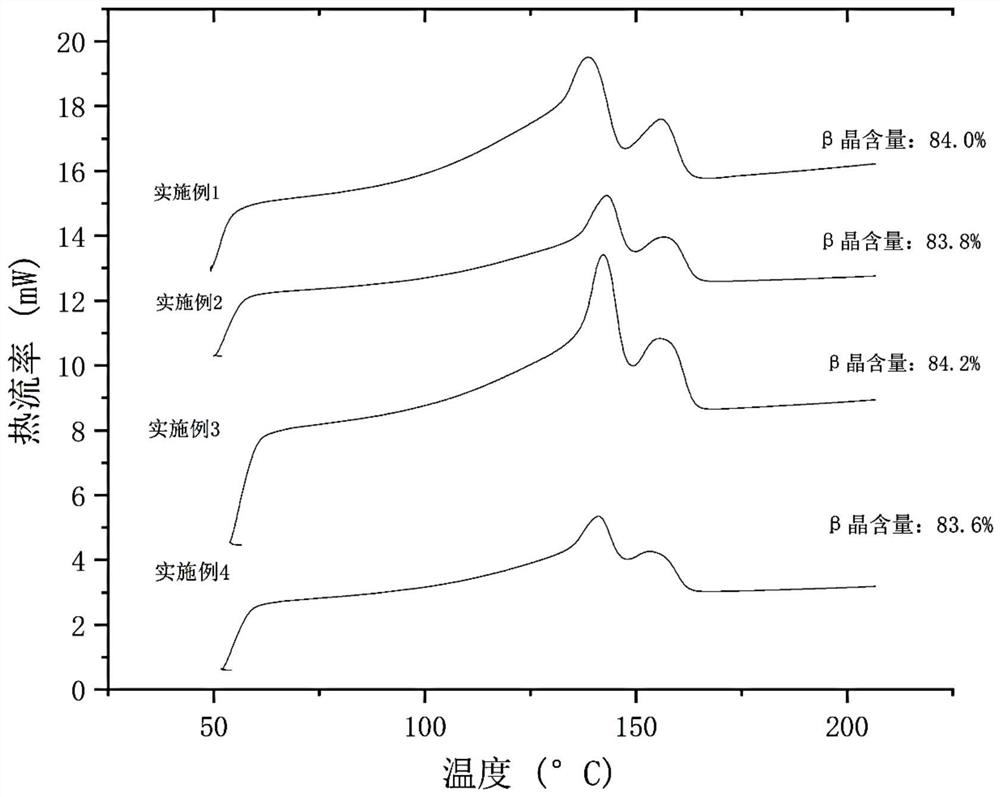

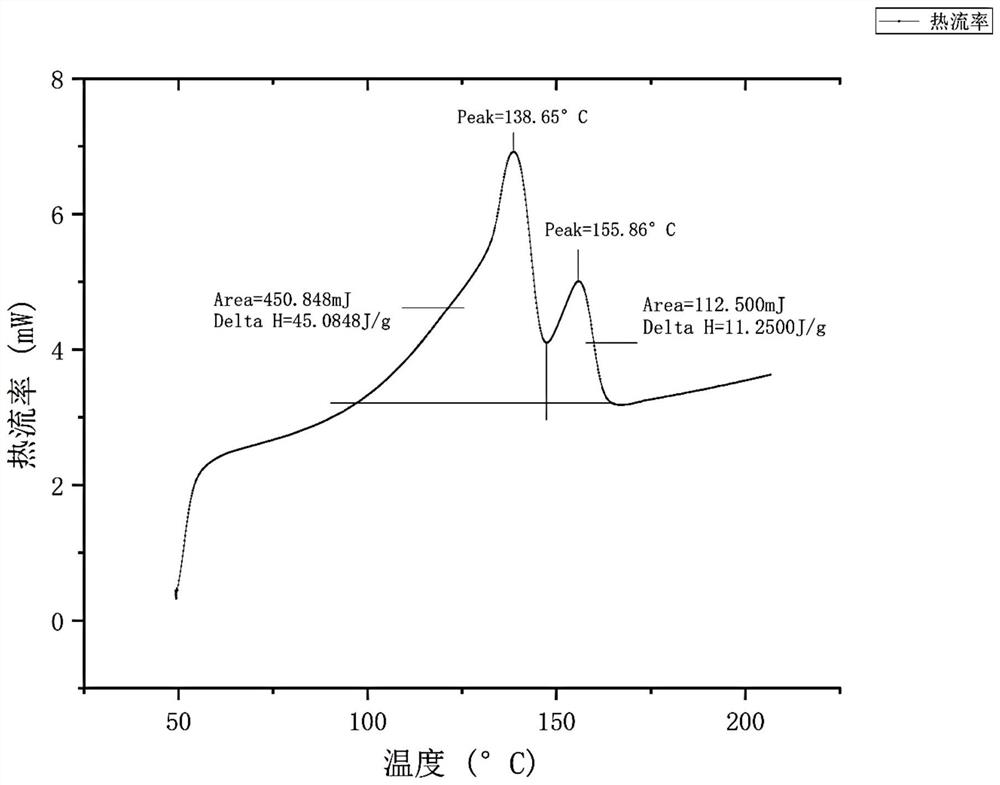

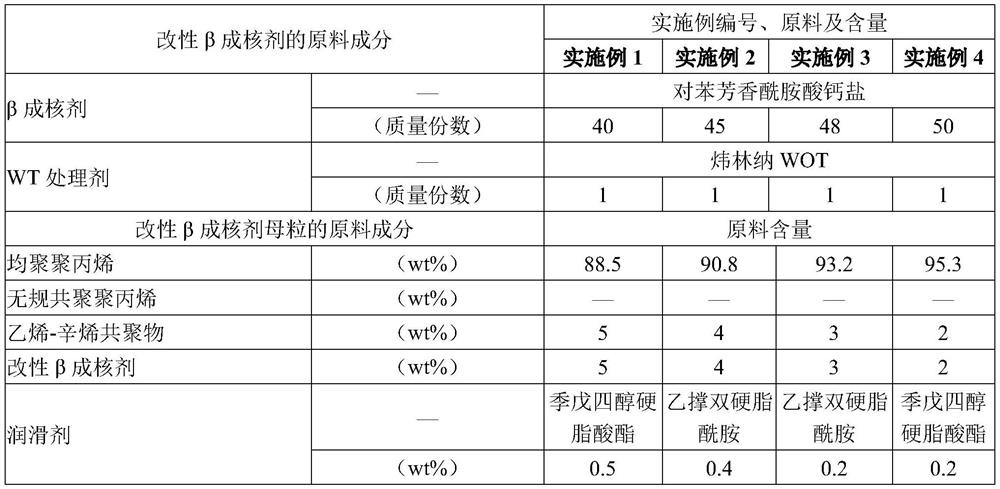

[0051] 1) Stir the β-nucleating agent in a high mixer at a speed of 900-960 rpm until the temperature reaches 80°C, add the WT treatment agent, then stir at a speed of 900-960 rpm until the temperature reaches 100°C, cool , to prepare a modified β-nucleating agent, the mass fraction ratio of the WT treatment agent and the β-nucleating agent is 1:(40-50).

[0052] 2) According to weight percentage, weigh 88.5wt%~95.3wt% of homopolypropylene, 2wt%~5wt% of ethylene-octene copolymer, 2wt%~5wt% of the modified β nucleating agent, 0.2 Wt%-0.5wt% of lubricant, and 0.5wt%-1wt% of antioxidant, mixed uniformly, put into extruder to extrude, cooled, pelletized, that is, the modified β-nucleating agent master pellets; the barrel temperature range of the extruder is 170-190°C, and the screw speed is 300-400rpm.

[0053] The melt index of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com